Production method for edge sealing type hidden buckle rock wool laminboard

A production method and sandwich panel technology, which is applied to roofs, roofs, buildings, etc. that use flat/curved panels, can solve problems such as scattering, damage and drop, and short service life, so as to increase service life and not easy to degumming , the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

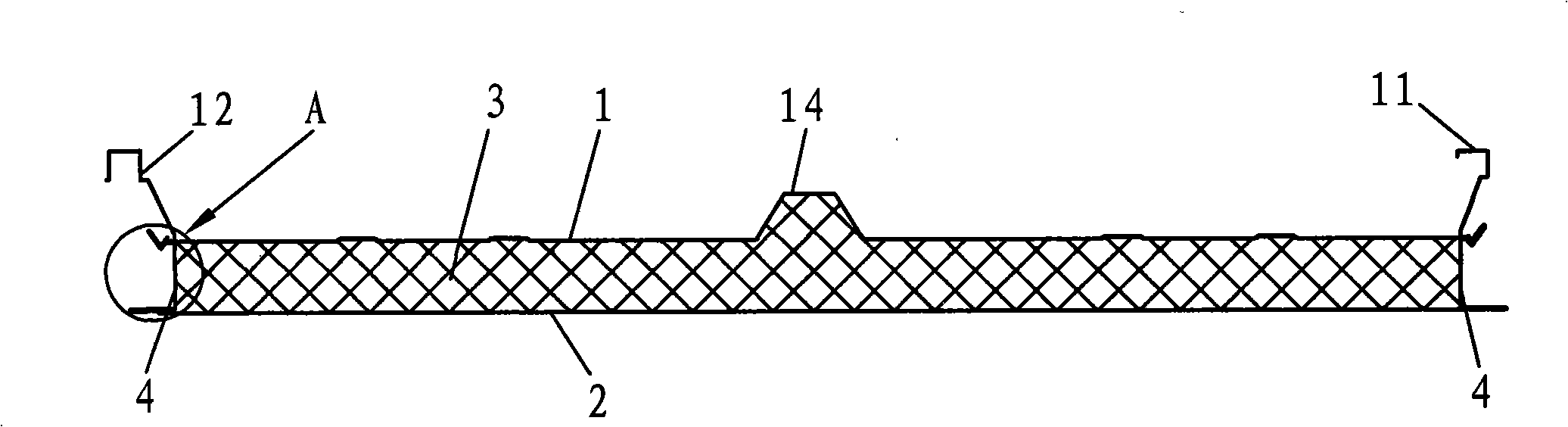

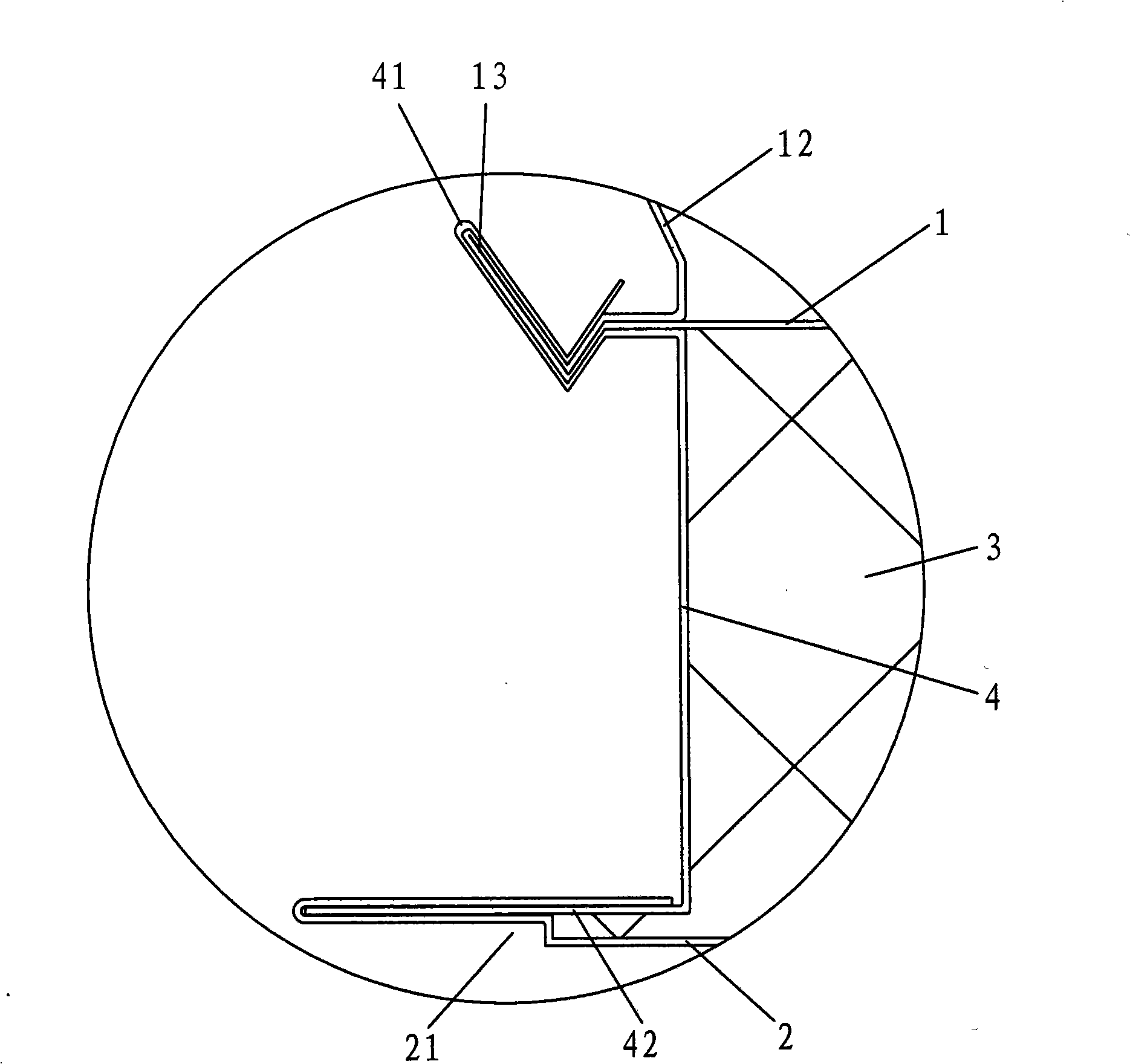

[0022] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1-2 , the edge-sealing concealed button rock wool sandwich panel made by the method of the present invention includes a panel 1 made of a metal plate, a bottom plate 2, and a core material made of rock wool and bonded between the panel 1 and the bottom plate 2 3. The panel 1 is a corrugated board structure with corrugated boards 14. The panel 1 with the corrugated board structure has better mechanical strength, strong bearing capacity, and is not easily deformed. The two sides of the panel 1 and the bottom panel 2 are respectively fastened and connected by two edge-sealing side panels 4 to form a closed frame. The edge-sealing side panels 4 can prevent water from leaking into the core material 3 from both sides of the sandwich panel. One side is bent upwards to form a hidden tile buckle 11, and the other side is bent upwards to form a tile buckle edge 12 that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com