Centrifuge and process for manufacturing anti-cracking type composite brake drum by adopting centrifuge

A centrifuge and centrifugal casting technology, which is applied in the field of auto parts manufacturing, can solve the problems of affecting the braking effect, reducing the service life of the brake drum, cracking, etc., and achieve the effects of not being easily deformed, improving the service life and good crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

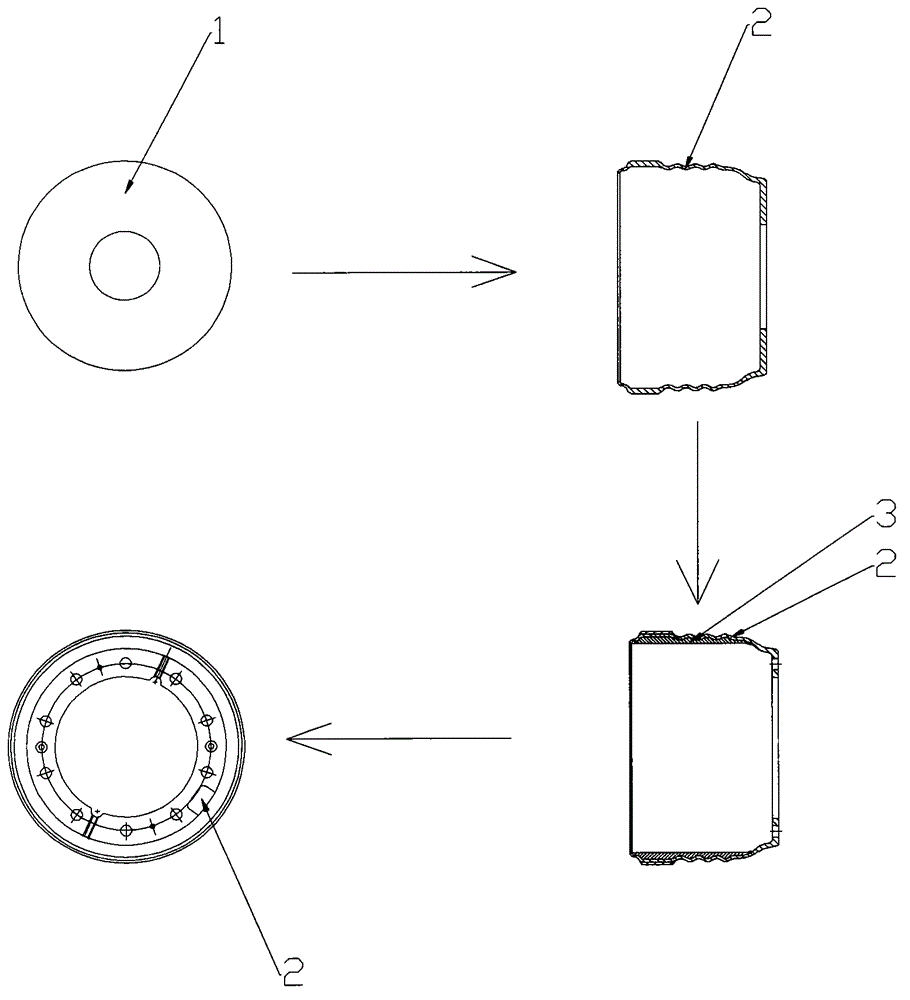

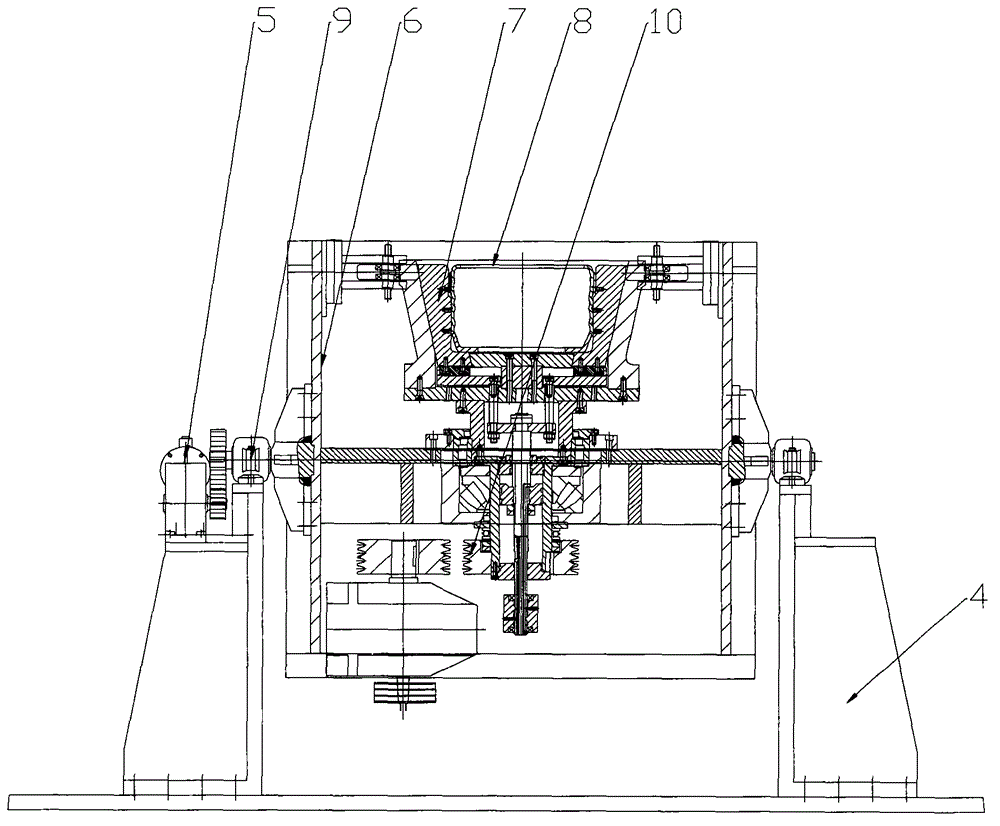

[0021] Such as figure 2 As shown, a centrifuge includes a support 4, a centrifugal casting chamber 6, and an overturning mechanism. The overturning mechanism includes an overturning frame 9, a speed changer 5 and a transmission mechanism, and the overturning frame 9 is arranged on the support 4 , the motor drives the overturn frame 9 to turn over relative to the support 4 through the transmission mechanism and the speed changer 5, and the inside of the centrifugal casting chamber 6 is provided with a locking shaping block 7, a centrifugal casting mechanism and a rotating mechanism 10, and the locking shaping block 7 can The position of the workpiece 8 is fixed and deformation of the workpiece 8 is prevented. The rotating mechanism 10 includes a transmission mechanism and a speed changer, and the main motor drives the locking shaping block 7 and the centrifugal casting mechanism to rotate relative to the centrifugal casting chamber 6 through the transmission mechanism and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com