Backlight module and liquid crystal display module

A backlight module and backplane technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of the support structure losing the height of the support cavity, the deformation of the support structure, and the deformation cannot be recovered, so as to improve the quality, height and The effect of small size and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

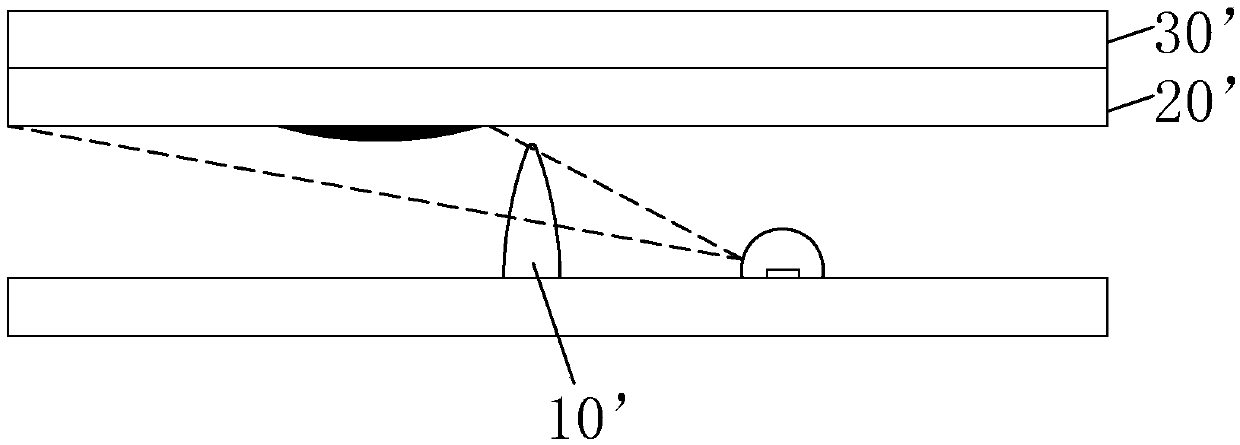

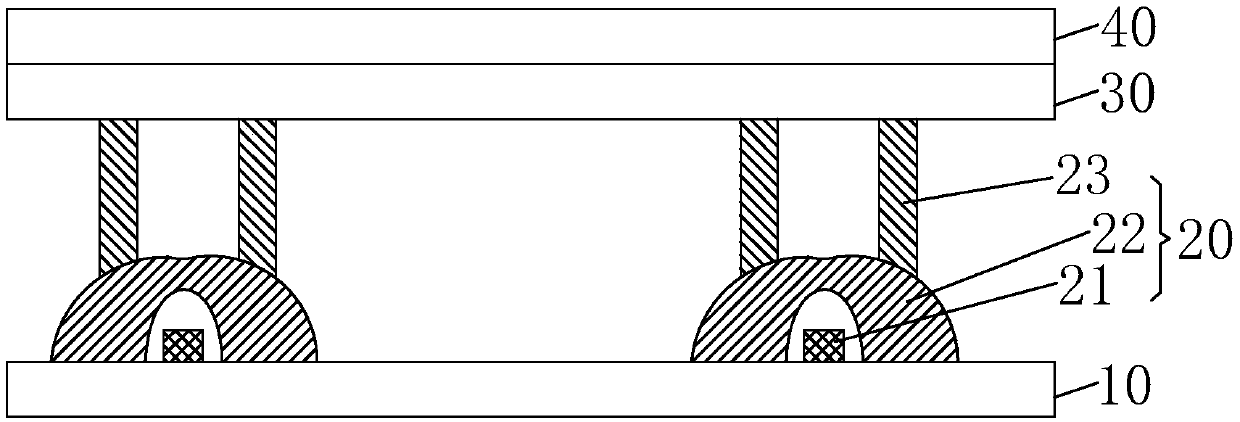

[0025] see figure 2 , the present invention provides a backlight module, comprising: a backplane 10, a plurality of light-emitting units 20 arranged at intervals on the backplane 10, and a diffusion plate 30 arranged on the light-emitting units 20;

[0026] The light emitting unit 20 includes a light emitting diode 21 , an LED lens 22 covering the light emitting diode 21 and at least one supporting structure 23 disposed on the LED lens 22 .

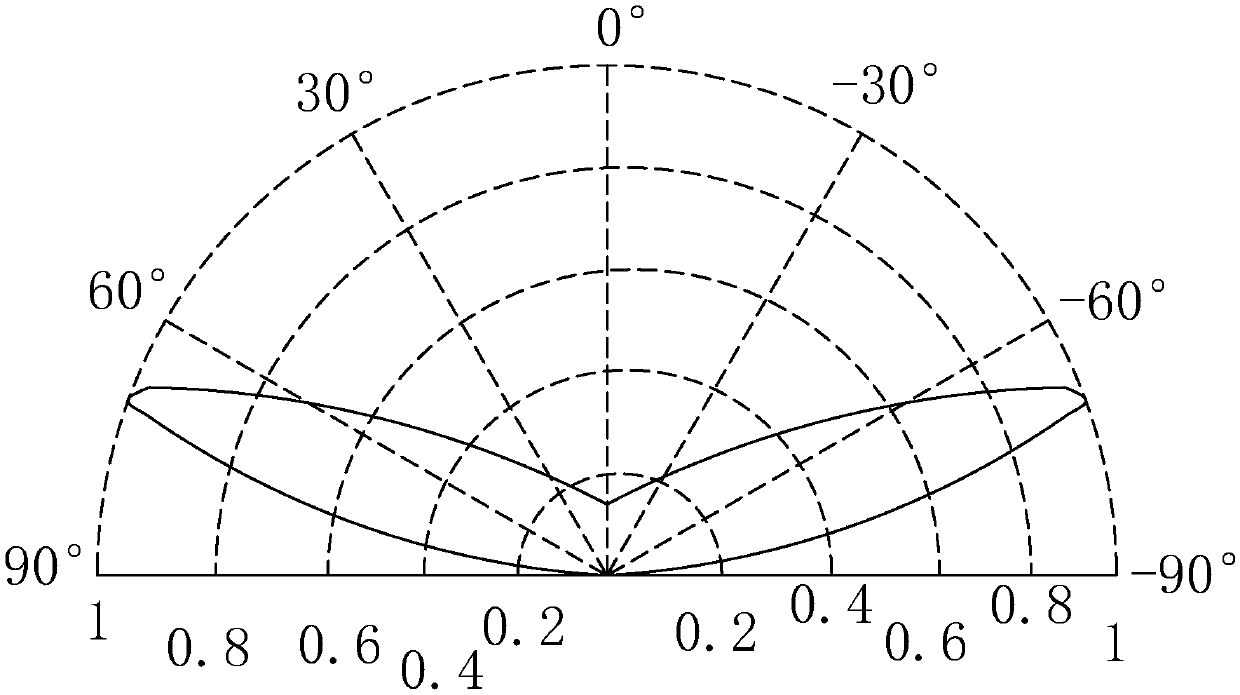

[0027] Specifically, the support structure 23 is located on the top of the LED lens 22 away from the light emitting diode 21 ; the light emitted by the light emitting diode 21 exits from the side of the LED lens 22 .

[0028] It should be noted that, in the light emitting unit 20 of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com