Preparation method of TEM (transverse electric and magnetic field) sample

A sample and cross-section technology, applied in the field of TEM sample preparation, can solve the problems of inapplicability, affecting the process, bending and deformation of TEM samples, etc., to achieve the effect of improving quality, good physical hardness, and improving analysis quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0036] Figure 1-8 It is a flow chart of a method for preparing a TEM sample of the copper seed crystal structure of the present invention, such as Figure 1-8 Shown, a kind of method for preparing the TEM sample of copper seed crystal structure specifically comprises the following steps:

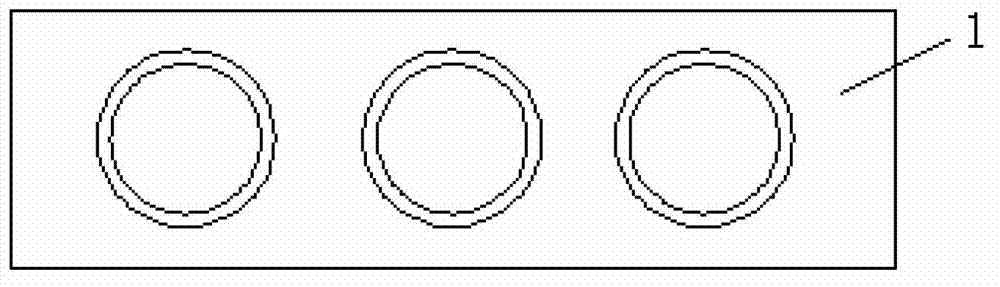

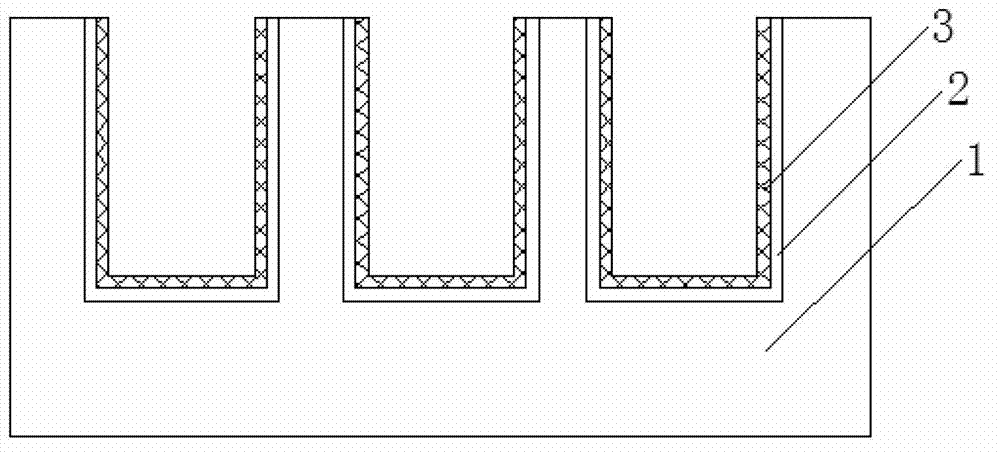

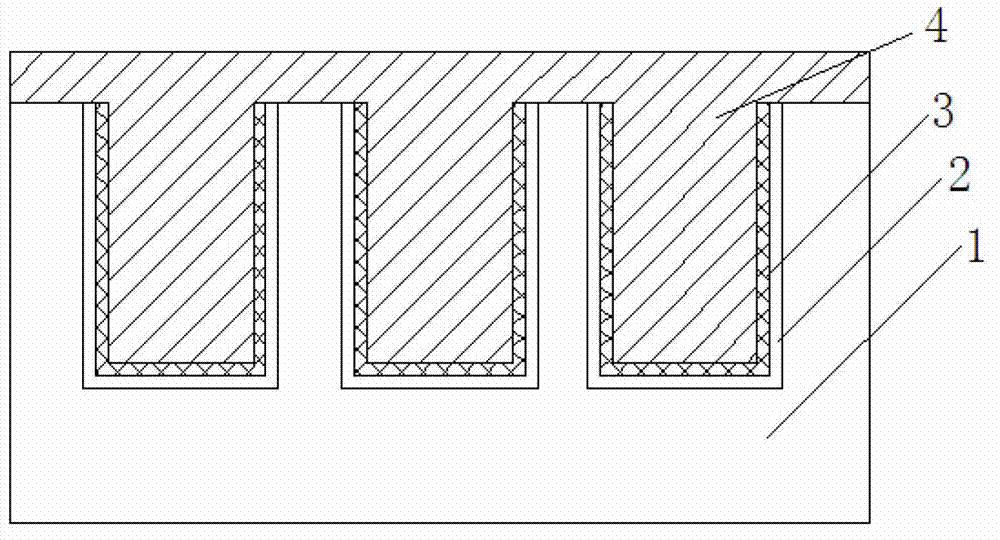

[0037] Step S1, providing a substrate 1 with a copper seed crystal structure, the trench is located in the substrate 1, the copper seed crystal structure includes a diffusion barrier layer 2 and a copper seed crystal layer 3, and the barrier layer 2 covers the bottom of the trench and its sidewall, the copper seed layer 3 covers the surface of the barrier layer 2, such as figure 1 and figure 2 The structure shown, where, figure 1 is a top view of a substrate with a copper seed structure, figure 2 is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com