Water flow inductive switch

A technology of water flow induction and switching, which is applied in the field of induction switching, can solve the problems of insensitivity of magnetic induction circuit boards, short service life, and rusting of iron filings, and achieve sensitive and stable induction pressure signals, sensitive induction pressure signals, and easy to use good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

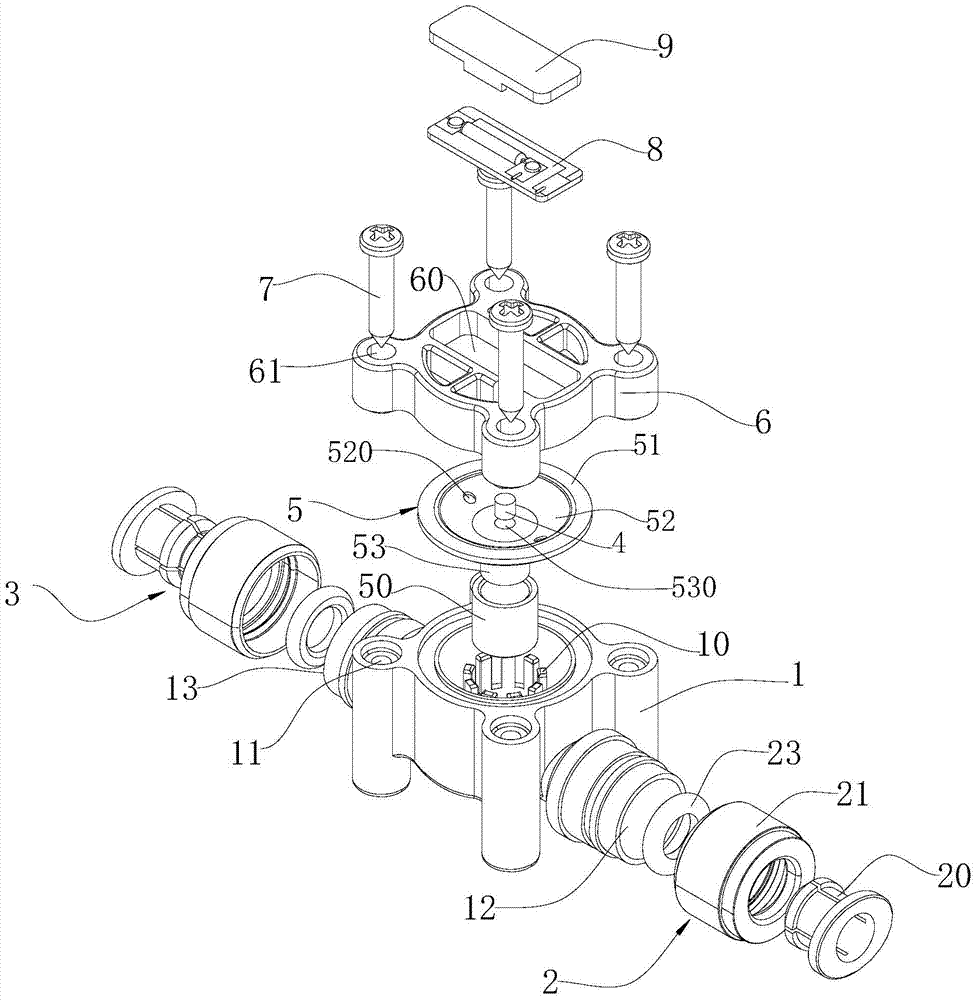

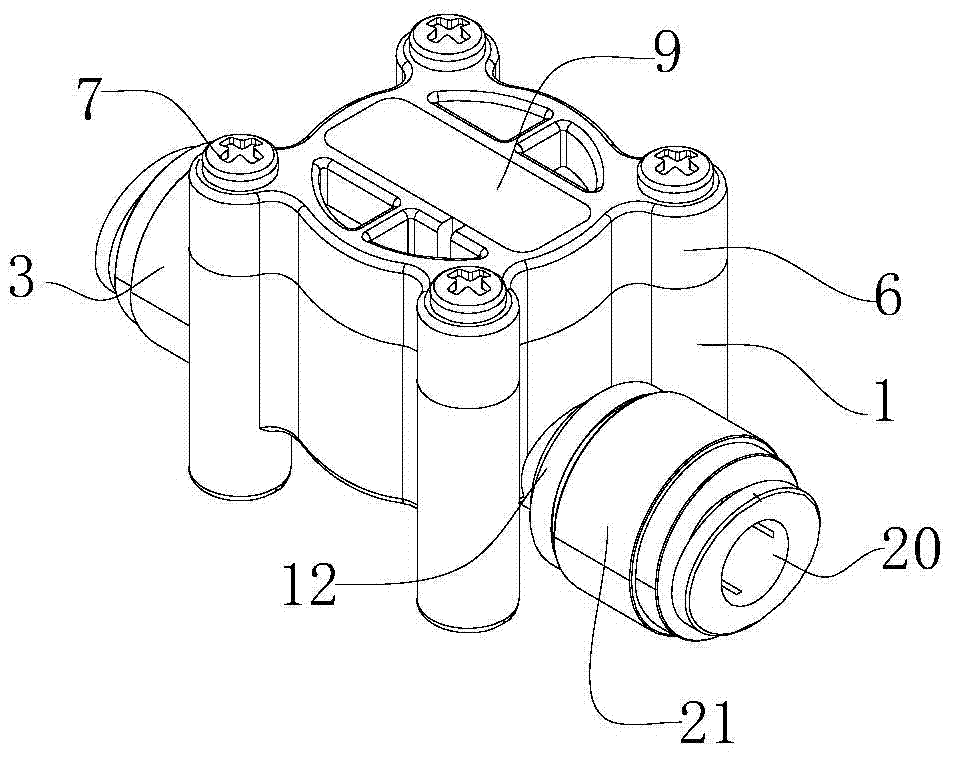

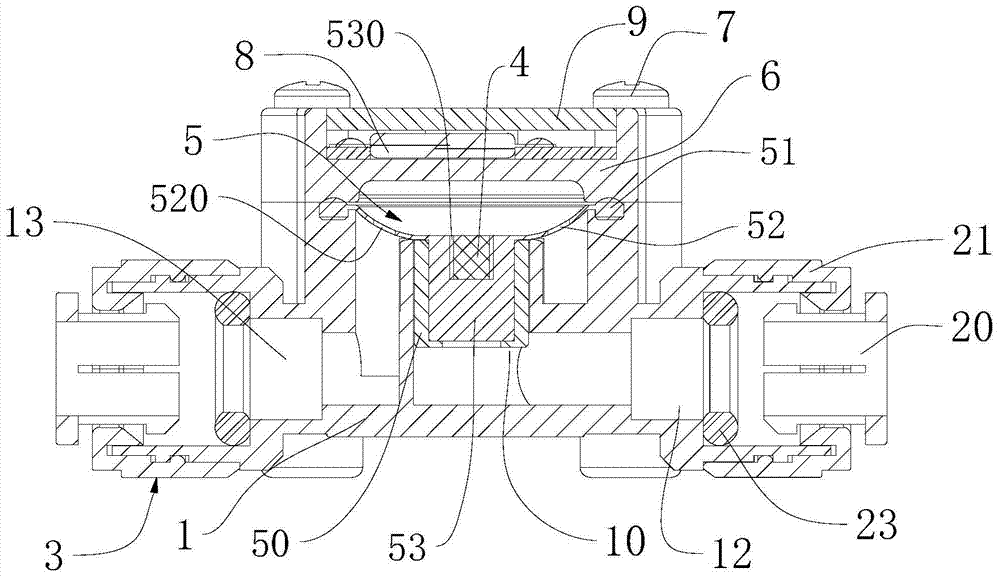

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 A water flow sensor switch is shown, which includes a housing, an elastic reset film 5 , a magnetic block 4 and a magnetic induction circuit board 8 . The housing is square as a whole and consists of a main housing 1 with an open top and an upper cover 6 sealingly covering the opening at the top of the main housing 1. Four screw holes 11 are arranged longitudinally along the four corners of the square main housing 1. Correspondingly, four through holes 61 are provided along the four corners of the square top cover 6 for the screws 7 to pass through, and the top cover 6 is fastened above the main casing 1 by four screws 7 to secure the main casing The opening at the top of the body 1 is sealed, and the way of sealing and covering is convenient for disassembly. Of course, for the housing, other known sealing and covering methods can also be used, and even the upper cover 6 and the main housing 1 can be...

Embodiment 2

[0032] Such as Figure 6 As shown, on the basis of Embodiment 1, the shape of the annular deformable membrane 52 of this embodiment is surrounded by an arc-shaped concave surface with an inner notch pointing obliquely upward, and the annular deformable membrane 52 in this embodiment is provided with two Pressure balance hole 520 .

[0033] The material of the annular deformable membrane 52 of the present embodiment is the following silica gel of raw material composition: 95 parts of vinyl silicone rubbers, 20 parts of fumed silica, 2 parts of diphenylsilanediol, 152 parts of titanium dioxide and benzoyl peroxide 2 servings. The above are all calculated in parts by weight and made through the existing silica gel manufacturing method.

Embodiment 3

[0035] Such as Figure 6 As shown, on the basis of Embodiment 2, the difference between this embodiment and Embodiment 2 is that the material of the annular deformable membrane 52 is silica gel with the following raw material components: 100 parts of vinyl silicone rubber, 22 parts of fumed silica, 3 parts of diphenylsilanediol, 148 parts of titanium dioxide and 1 part of benzoyl peroxide. The above are all calculated in parts by weight and made through the existing silica gel manufacturing method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com