Tile flatness detecting method and device

A technology for flatness detection and tiles, which is applied in the field of ceramic processing, and can solve problems such as deformation data and calibration difficulties of ceramic tiles that are easy to miss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

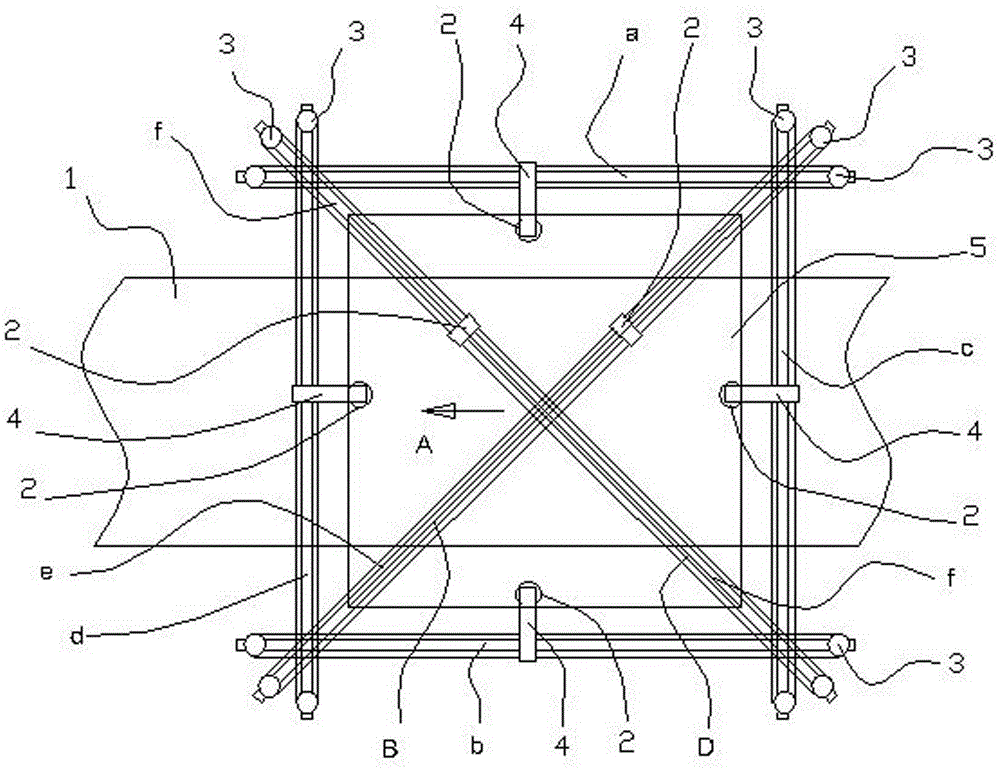

[0013] Embodiment one: if figure 1 As shown, the tile flatness detection device of the present invention is realized in this way, including an upper linear guide rail a arranged horizontally on both sides of the tile conveying device 1, a lower linear guide rail b, and two vertical rails perpendicular to the tile conveying direction A. Linear guide rails c, d, oblique linear guide rails e, f corresponding to tile diagonal directions B, D, and laser displacement sensors 2 slidingly arranged on each linear guide rail. The detection direction of laser displacement sensor 2 is downward, and each linear guide rail The laser displacement sensor 2 on the top is driven by the electric power mechanism 3 to move.

[0014] Here, a movable frame 4 driven by the electric power mechanism 3 is slidably arranged on the linear guide rail, and the movable frame 4 floats out to the top of the ceramic tile 5, and the laser displacement sensor 2 is arranged on the movable frame 4 floating out, so ...

Embodiment 2

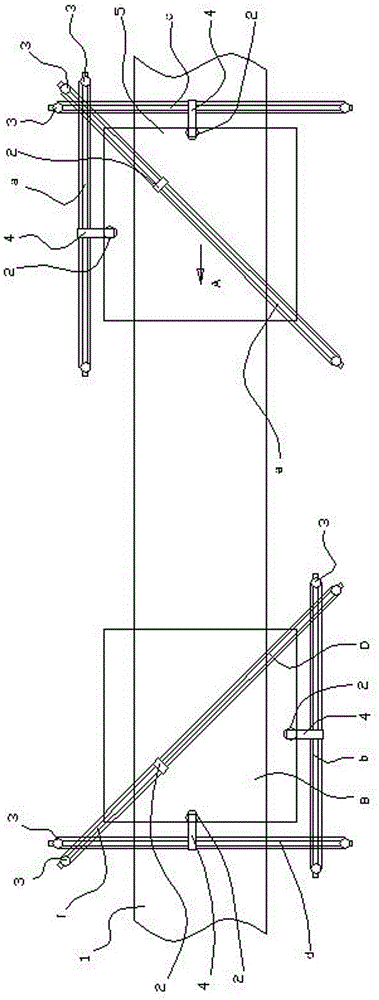

[0015] Embodiment two: if figure 2 As shown, this embodiment is based on the first embodiment, the upper linear guide rail a with the laser displacement sensor 2 arranged horizontally on one side of the tile conveying device 1, and one of the linear guides a perpendicular to the tile conveying direction A The vertical linear guide rail c of the laser displacement sensor 2 and the oblique linear guide rail e with the laser displacement sensor 2 corresponding to one pair of corner directions B of the tiles are the first group, which are arranged at the level of the other side of the tile conveying device 1 The upper linear guide rail b with laser displacement sensor 2, the other vertical linear guide rail d with laser displacement sensor 2 perpendicular to the tile conveying direction A, and the vertical linear guide rail d with laser displacement sensor 2 corresponding to the other diagonal direction D of the tiles. The oblique linear guide rail f of sense 2 is the second grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com