Casting continuous cleaning flow line and method thereof

An assembly line and casting technology, which is applied in the field of continuous casting cleaning line, can solve the problems of large workplace area, low production efficiency, high labor intensity of workers, etc., and achieve the effect of saving workplace area, reducing floor space, and saving manpower consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

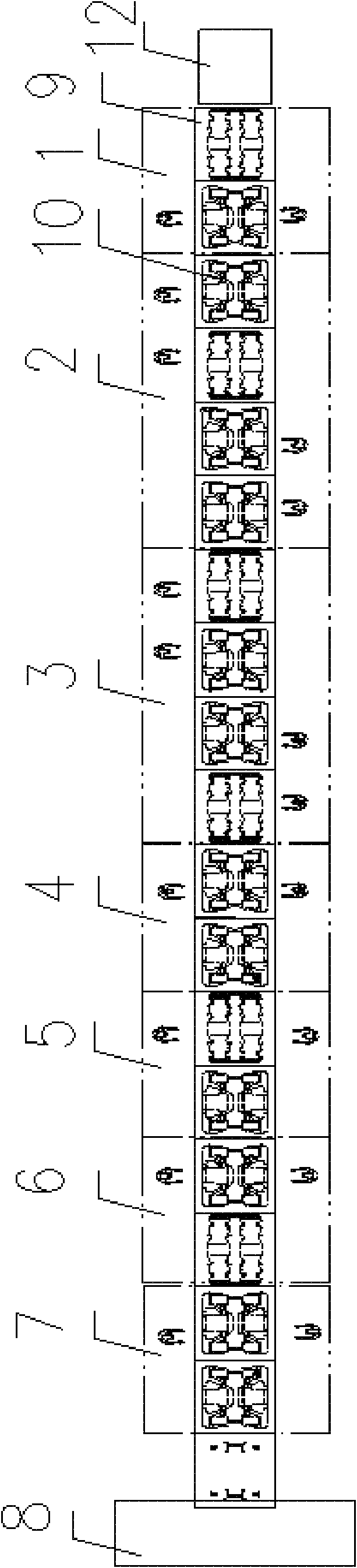

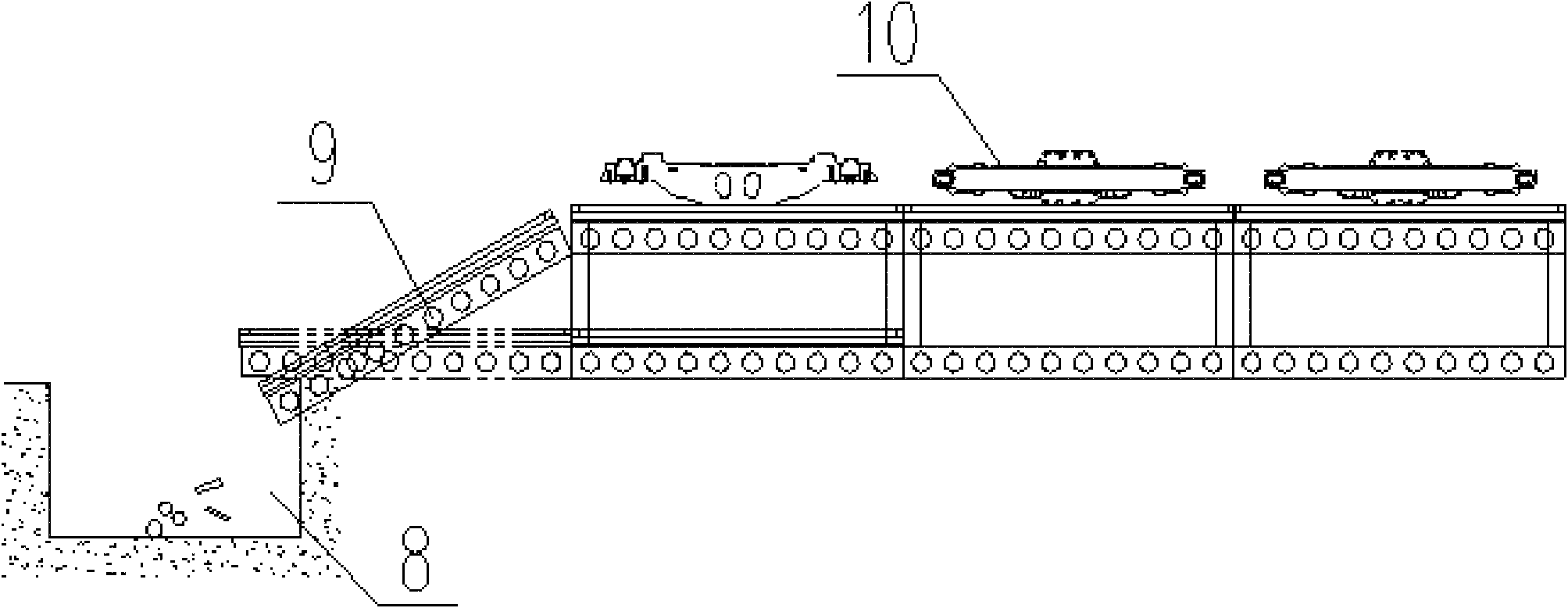

[0033] figure 1 It is a schematic diagram of the upper pipeline structure provided by the first embodiment of the present invention; figure 2 It is a schematic diagram of the bottom plate circulation provided by the first embodiment of the present invention.

[0034] The continuous casting cleaning line provided by this embodiment includes: a bottom plate 9, an upper line and a lower line. The upper line (also called the work roller) is figure 1 As shown, it includes the bottom plate feeding station, the upper part station 1, the primary cutting station 2, the primary gouging station 3, the turning station 4, and the secondary cutting station 5, which are sequentially set from the forward direction of the casting. There are nine stations for secondary gouging station 6, lowering station 7, floor automatic cleaning and return station. The casting residue collected by the automatic cleaning and return station of the bottom plate is poured into the residue collecting hopper 8. The ...

Embodiment 2

[0036] The continuous cleaning assembly line for castings provided by this embodiment includes: a bottom plate, an upper layer assembly line, and a lower layer assembly line. The bottom plate has a total of 18 pieces, and each two pieces of the bottom plate are placed side by side as a group, a total of 9 groups, and each station is composed of groups. The unit cleans up, with four castings on each group. The upper assembly line (also known as the work roller table) includes the bottom plate feeding station, the upper part station, the primary cutting station, the primary gouging station, the turning station, the secondary cutting station, and the secondary gouging station set in sequence. Automatic cleaning and return station of work station, loading station and bottom plate. The lower pipeline and the upper pipeline are connected end to end to form a closed operating loop.

[0037] The bottom plate circulates among the stations, and the bottom plate circulates between stations...

Embodiment 3

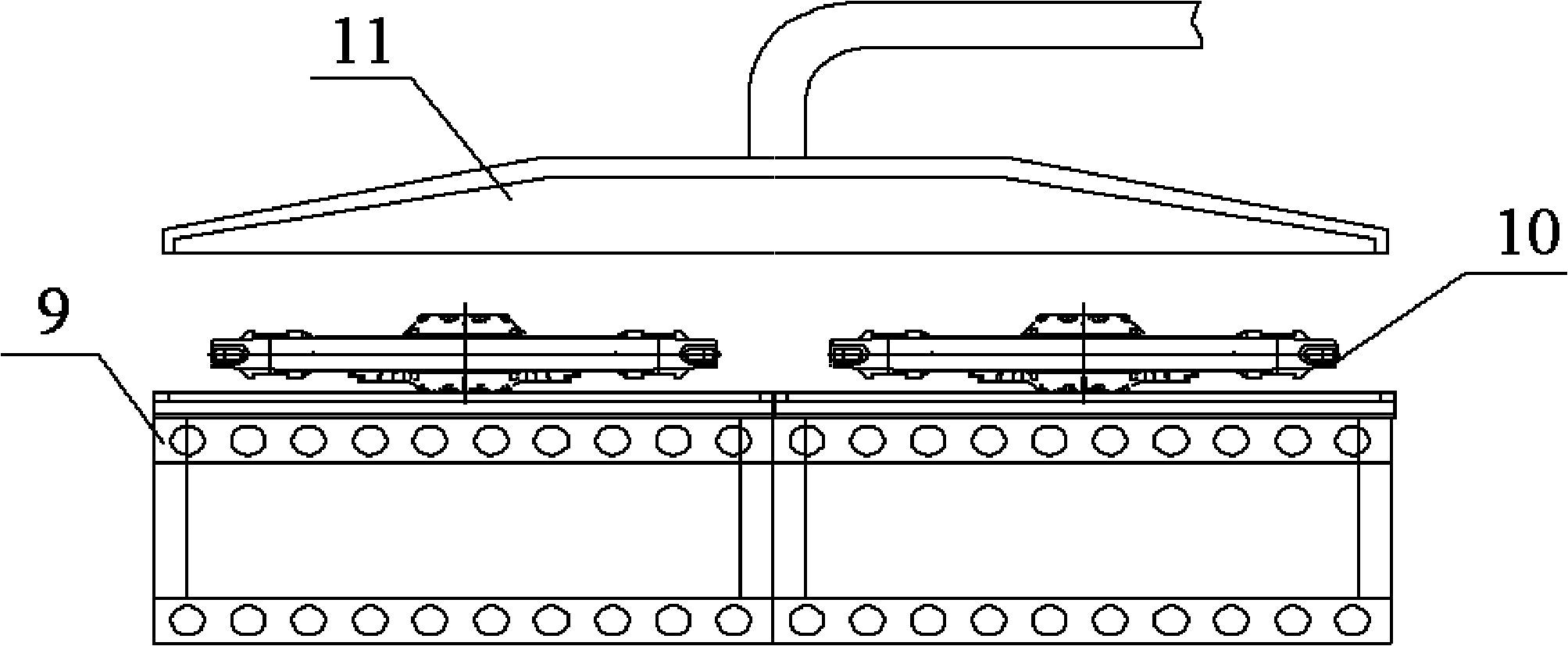

[0041] image 3 It is a schematic diagram of the structure of the top cover type dust collector of the third embodiment of the present invention.

[0042] The bottom plate, upper pipeline, and lower flow of the casting continuous cleaning line provided in this embodiment are the same as those in the second embodiment. The difference is that the casting continuous cleaning line provided in this embodiment has a single cutting station and a gouging station , The top of the operating point of the secondary cutting station and the secondary gouging station is provided with a top cover type dust collector 11, such as image 3 As shown, the casting 10 is placed on the bottom plate 9, and an inverted bucket-shaped top cover type dust collector 11 is arranged above the casting 10. The top cover type dust collector 11 can capture the smoke and dust generated by the heat floating and the smoke generated by the high-temperature arc combustion of the gouging carbon rod. The smoke and dust are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com