Steel pipe automatic drilling robot

A robot, steel pipe technology, applied in portable drilling rigs, metal processing equipment, drilling/drilling equipment, etc., can solve the problems affecting the quality and use of drilling, inconvenient manual operation, unstable drilling, etc., to achieve accurate Positioning multi-angle punching, simple structure, anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

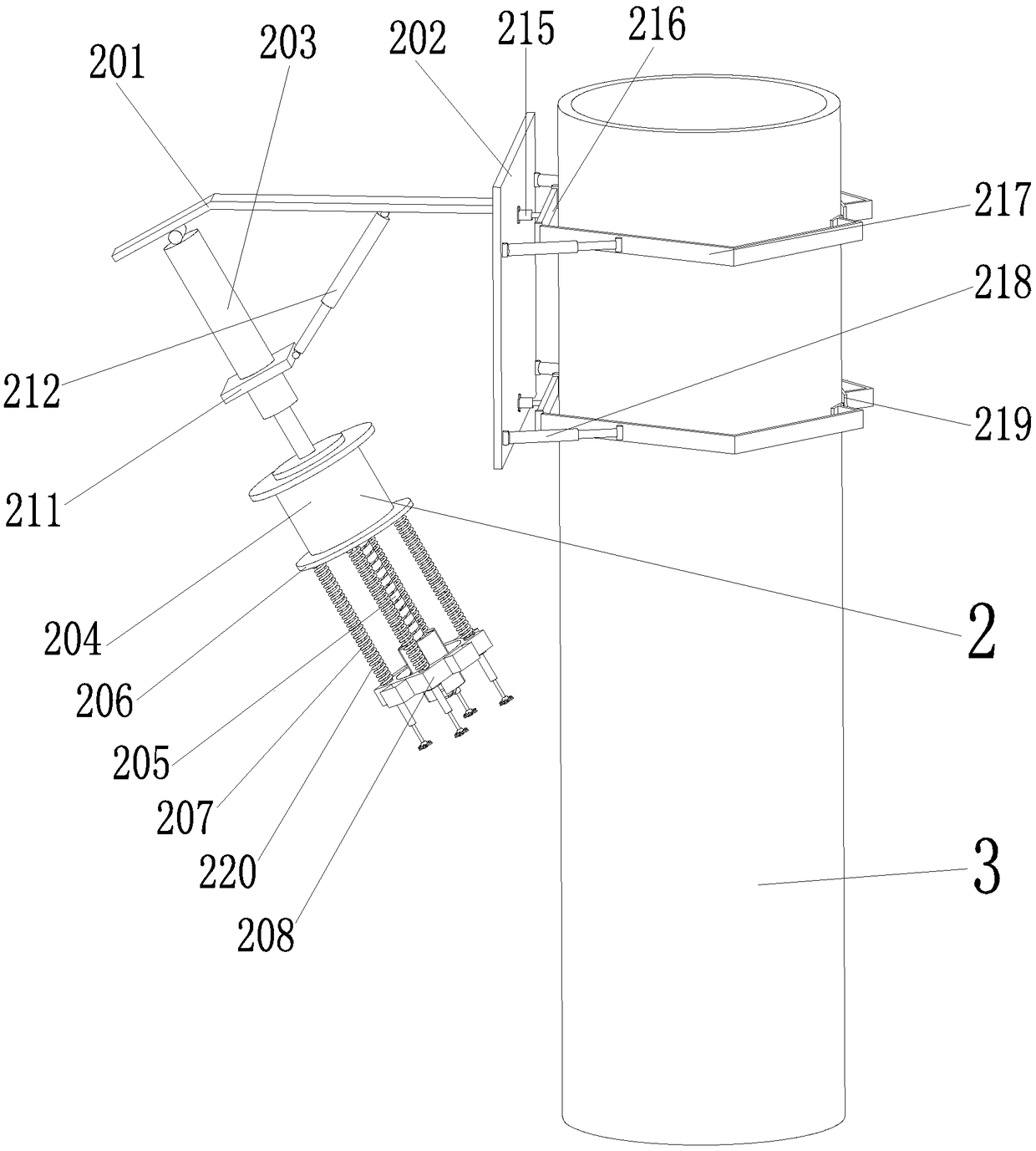

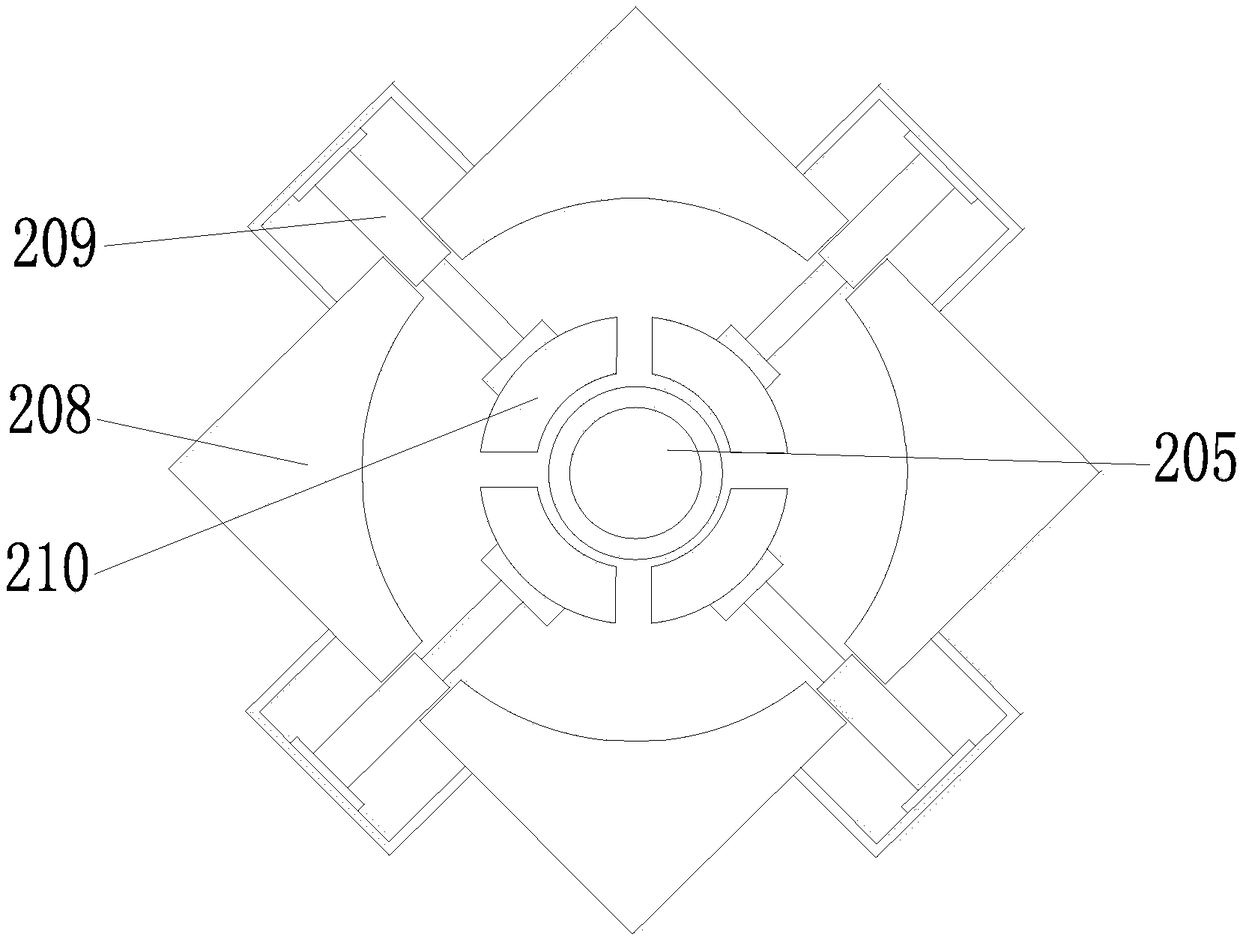

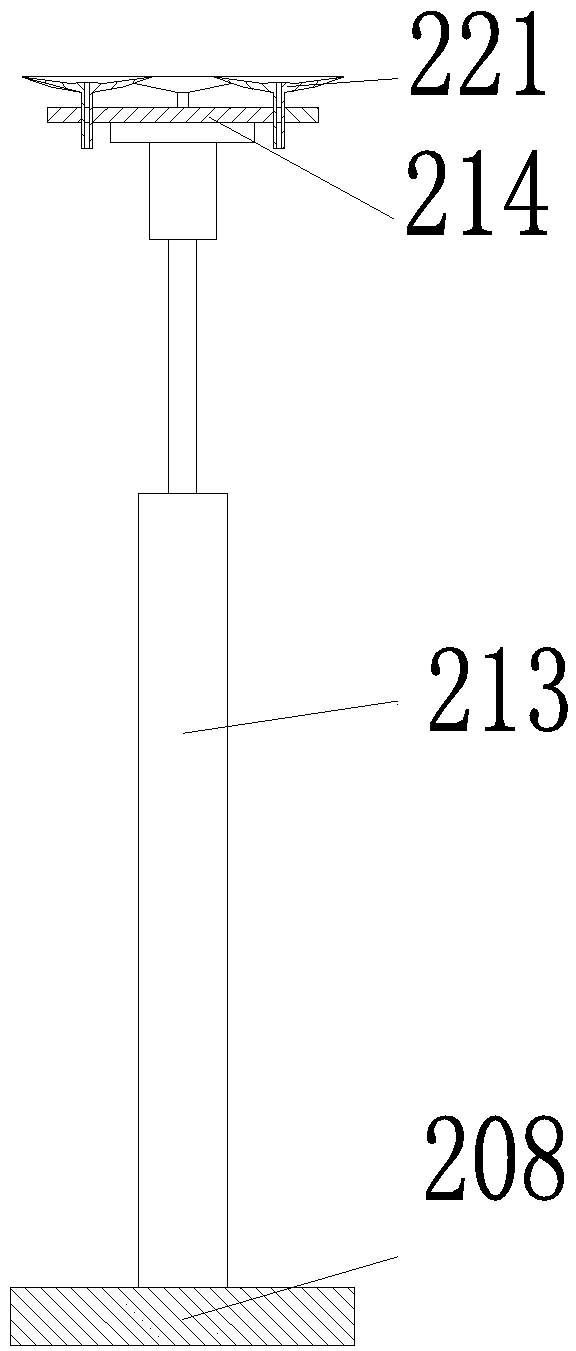

[0016] Such as Figure 1 to Figure 3 As shown, a robot for automatic drilling and processing of steel pipes includes an actuator 2 and a steel pipe body 3. The actuator 2 abuts against the outer wall of the steel pipe body 3. Leaning against the steel pipe body 3, the actuator 2 punches holes in the steel pipe body 3 from different angles, which is convenient to operate, saves time and effort, and is accurate in punching, and is not easy to miss.

[0017]The actuator 2 includes a connection plate 201, a locking plate 202, an actuator cylinder 203, a drilling drive motor 204, an inclined hole drill bit 205, an auxiliary drilling plate 206, an auxiliary telescopic rod 207, a positioning plate 208, and an auxiliary electric push rod 209 , auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com