Optical fiber, optical fiber connecting method, and optical connector

A technology of optical fiber and connecting part, which is applied to optical fiber connectors, connection methods between single-mode optical fibers and the fields of optical connectors, optical fibers and their optical fiber connectors. It can solve the problems of large changes in temperature characteristics and increased connection losses, and achieve Effects of preventing deterioration of mechanical strength, prevention of strength deterioration, and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

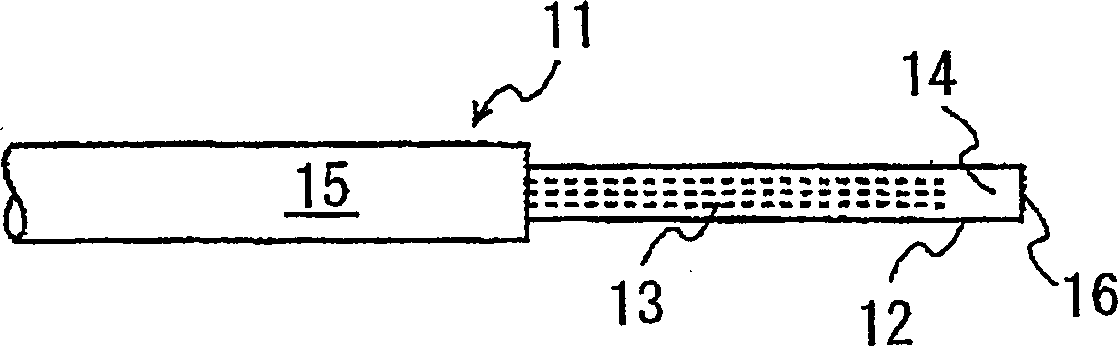

[0119] figure 1 It is a side view showing a photonic crystal fiber (PCF) according to a preferred embodiment 1 of the present invention.

[0120] First, PCF11 of this embodiment and Figure 5 PCF41 explained in , so its detailed description will be omitted. However, the optical fiber is used in the state of an optical fiber core covered by a coating made of UV resin around the cladding, and the connecting part connected to a ferrule or other connector is stripped Use in such a way that the coating is removed.

[0121] like figure 1 As shown, the cavity 13 near the connection end 12 of the PCF 11 is filled with a UV curable resin 14 having a lower refractive index than quartz as a filler. The UV curable resin 14 is liquid at normal temperature before use, and is cured by irradiating ultraviolet rays. The UV curable resin used in this embodiment is the epoxy-based fluorine-containing UV curable resin 14 whose refractive index after curing is adjusted to 1.42.

[0122] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com