Hollow axle bridge structure and light wheel pair

A hollow shaft, lightweight technology, applied in the field of rail vehicles, can solve the problems of the difficulty of reducing the weight of the bogie frame and the weight of the wheelset with unsprung mass, so as to reduce the fatigue load, reduce the mass, and improve the axle load. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

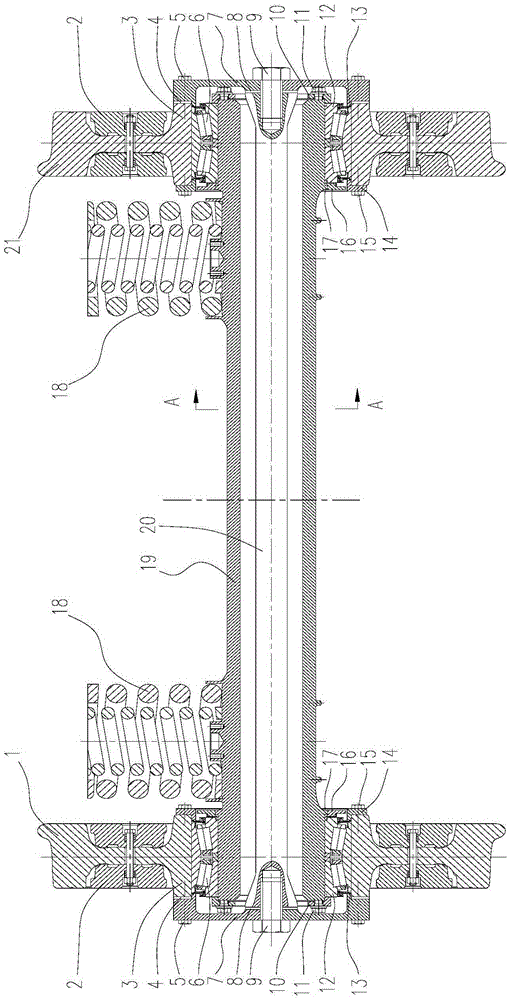

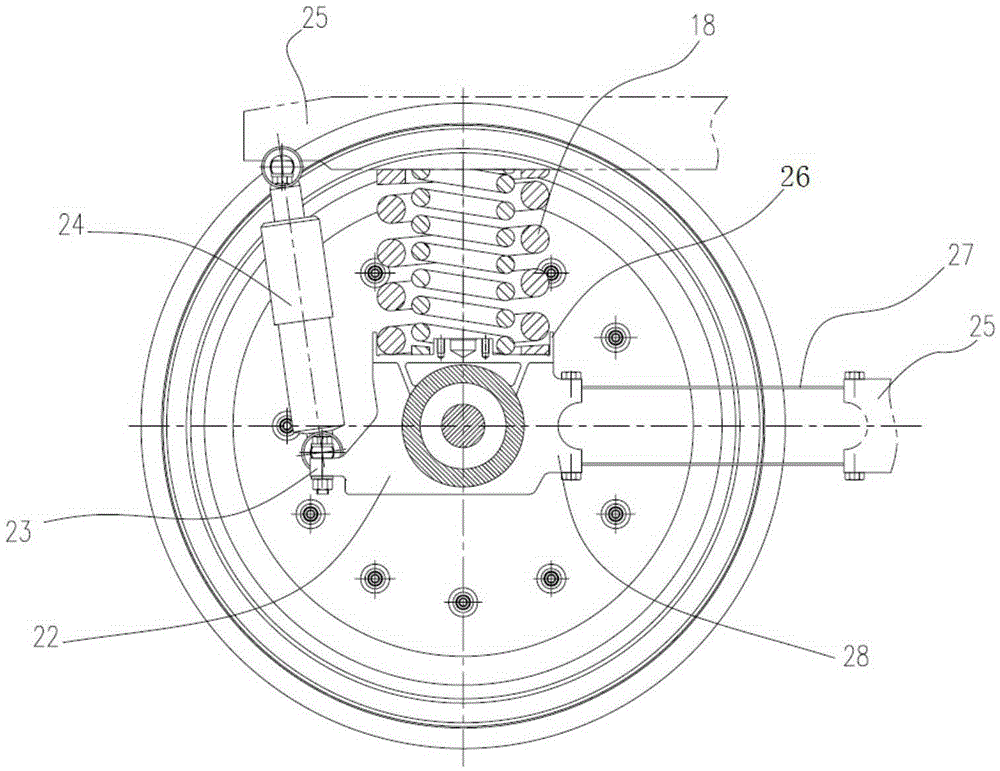

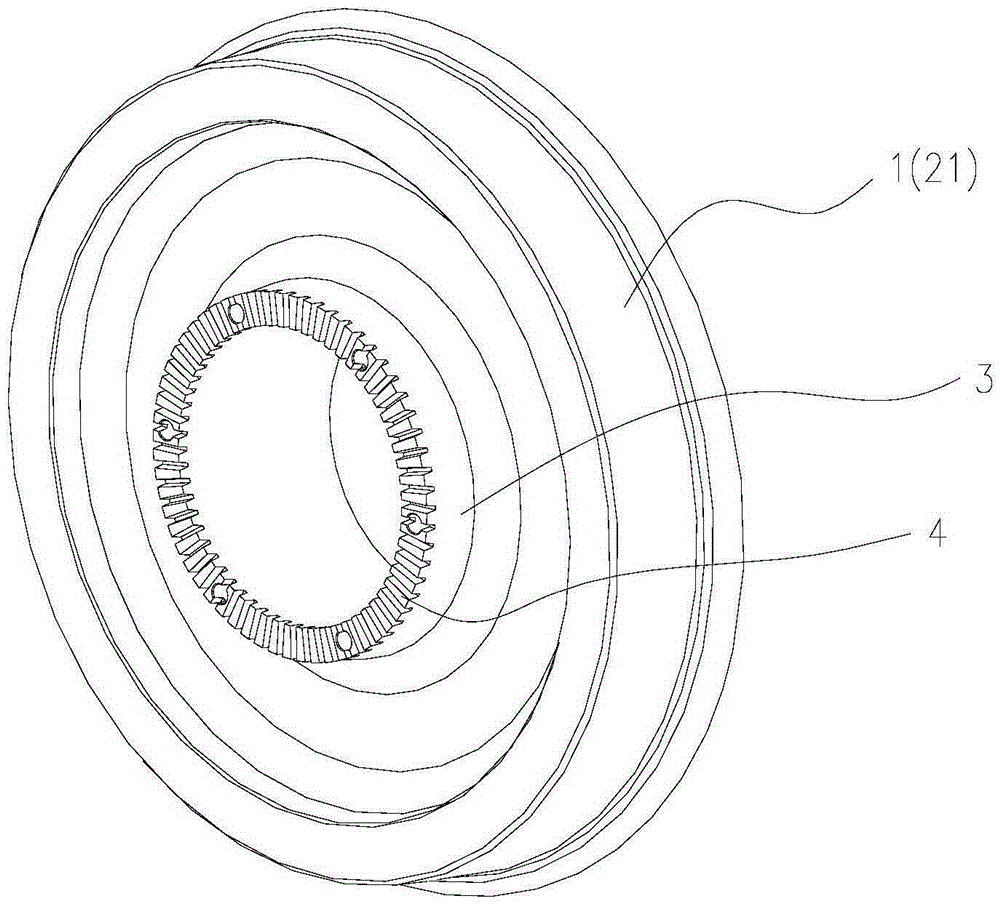

[0038] A lightweight wheel set such as figure 1 As shown, the wheel set basically has a left-right symmetrical structure. The hub 3 of the first wheel 1 cooperates with the outer ring 13 of the bearing 6 , and the outer ring 13 of the bearing 6 is pressed against both sides by the transmission disc 7 and the inner end cover 14 . The screw 5 is used for fastening the transmission disc 7 and the hub 3 , and the screw 15 is used for fastening the inner end cover 14 and the hub 3 . Therefore, the first wheel 1 forms an integral body with the outer ring 13 of the bearing 6, the transmission disc 7, and the inner end cover 14 when running.

[0039] Such as figure 1 As shown, the two ends of the shaft bridge 19 cooperate with the inner ring 12 of the bearing 6 , and the inner ring 12 of the bearing 6 is pressed against both sides by the gland 10 and the retaining ring 16 . The retaining ring 16 is in contact with the shoulder 17 of the shaft bridge 19, the screw 11 connects the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com