Cold-rolling acid-pickling corrosion inhibitor and preparation method thereof

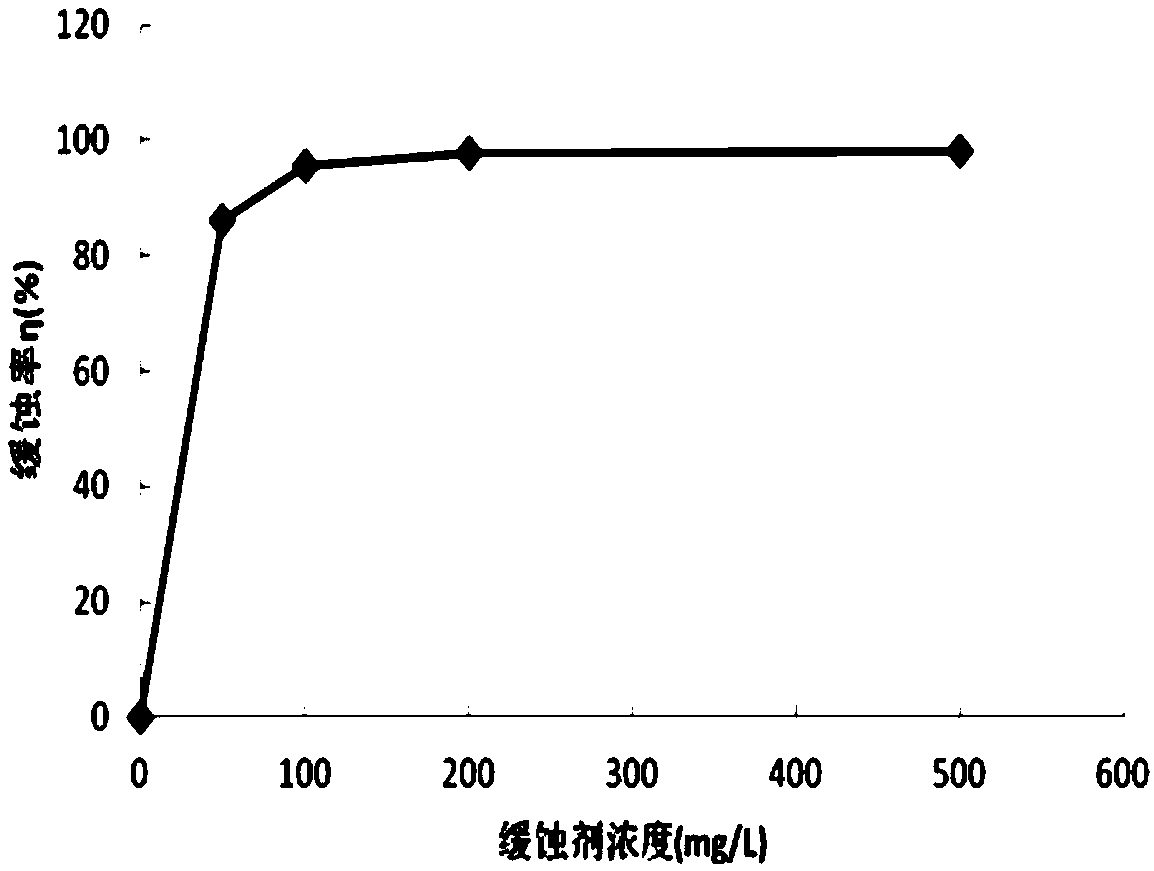

A technology of pickling corrosion inhibitor and corrosion inhibitor, which is applied in the field of metal surface treatment, can solve the problems of low corrosion efficiency, large dosage, poisonous and harmful, and achieve the effect of simple synthesis method, low dosage and reduction of acid mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

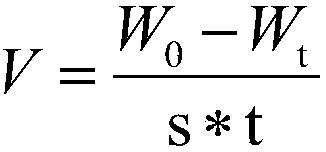

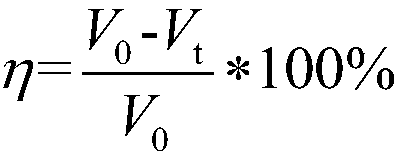

Image

Examples

Embodiment 1

[0026] A kind of cold rolling pickling corrosion inhibitor, its preparation method comprises the steps:

[0027] 1) Add vitamin B3 and organic amine (myristylamine) to ethanol at a molar ratio of 1:1, and mix well;

[0028] 2) Thionyl chloride was added to the obtained reaction solution, heated to 70°C for 4 hours, then stirred at room temperature for 3.5 hours, and the alcohol solvent was distilled off to obtain the cold rolling pickling corrosion inhibitor.

Embodiment 2

[0030] A kind of cold rolling pickling corrosion inhibitor, its preparation method comprises the steps:

[0031] 1) Add vitamin B3 and organic amine (myristylamine) to ethanol at a molar ratio of 1:1.5, and mix well;

[0032] 2) Thionyl chloride was added to the obtained reaction solution, heated to 70°C for 4 hours, then stirred at room temperature for 3.5 hours, and the alcohol solvent was distilled off to obtain the cold rolling pickling corrosion inhibitor.

Embodiment 3

[0034] A kind of cold rolling pickling corrosion inhibitor, its preparation method comprises the steps:

[0035] 1) Add vitamin B3 and organic amine (myristylamine) to ethanol at a molar ratio of 1.5:1, and mix well;

[0036] 2) Thionyl chloride was added to the obtained reaction solution, heated to 70°C for 4 hours, then stirred at room temperature for 3.5 hours, and the alcohol solvent was distilled off to obtain the cold rolling pickling corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com