Patents

Literature

39results about How to "Less acid mist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pickling solution containing compounded passivating agent, and preparation method thereof

The invention belongs to the stainless steel casting cleaning field, and relates to a passivating pickling solution obtained through adding an organic substance to an HNO3-HF base acid solution and compounding. The pickling solution comprises 3.3-37.5mass% of HNO3, 0.7-7.5mass% of HF, 1.3-13.5mass% of the compounded passivating agent, and the balance water. A polluted stainless steel casting is cleaned by the pickling solution to recover the metal luster originally possessed by the casting. The pickling solution forms a compact passivating film on the surface of the casting, so bright beauty maintenance and no rusty spot are realized after the casting is stored for a long term. The pickling solution has the characteristics of very small acid mist, benefiting for the environmental protection and the body health of an operation personnel, large pickling amount, and low pickling cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

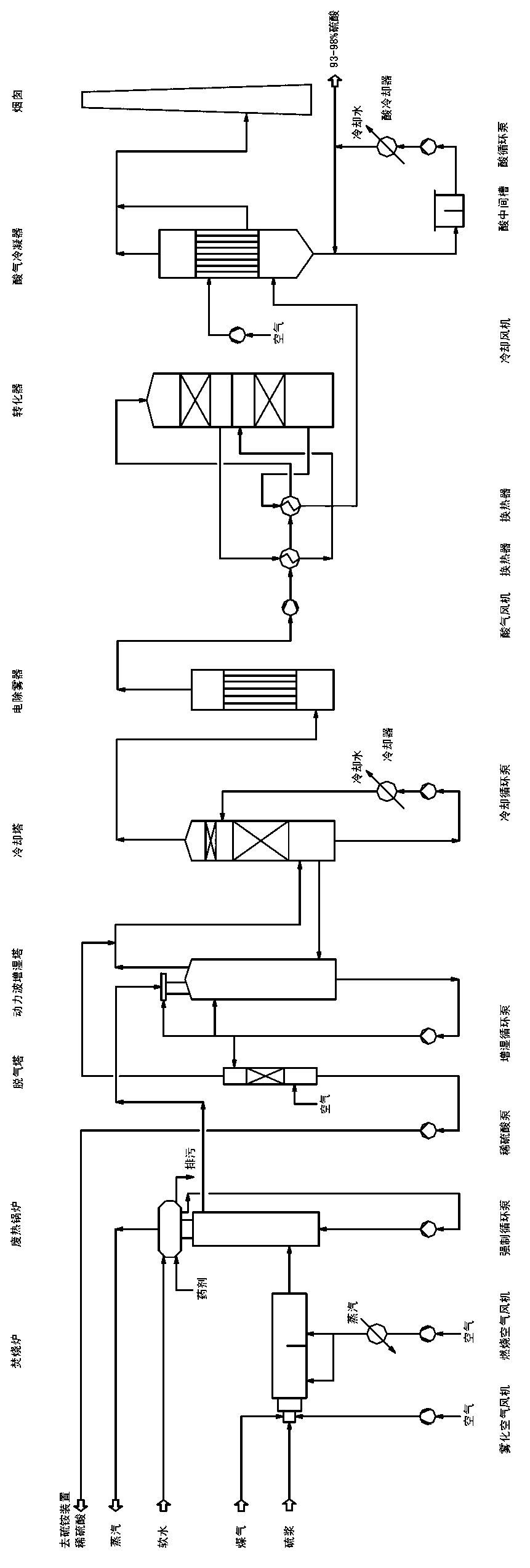

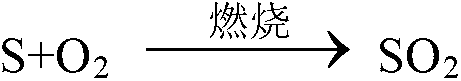

Technology for preparing sulfuric acid

The invention relates to a technology for preparing sulfuric acid, in particular to a technology for preparing sulfuric acid by taking low-quality sulfur and a waste salt liquid containing sulfur that are generated by a coke oven gas wet oxidation desulfurization technology which takes ammonia as an alkali source and takes quinone, cobalt and ferrum compositions such as HPF as catalysts as raw materials, and through processes of incineration, waste heat recovery, wet purification, wet contact method conversion, and condensation into acid. The technology thoroughly solves the problem of treatment of a waste desulfurization liquid and low-quality sulfur that are generated by the coke oven gas wet oxidation desulfurization technology which takes the quinone, cobalt and ferrum compositions such as HPF, PDS and ZL as the catalysts, so that the desulfurization technology is completed; produced sulfuric acid can serve as a raw material for deamination of coal gas of a factory, and for production of ammonium sulfate, can be exported as sulfuric acid goods; and double purposes of resource recycle and environmental protection are achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

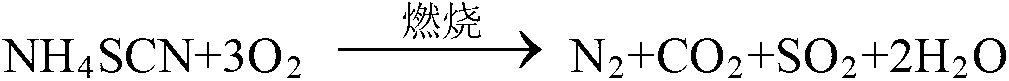

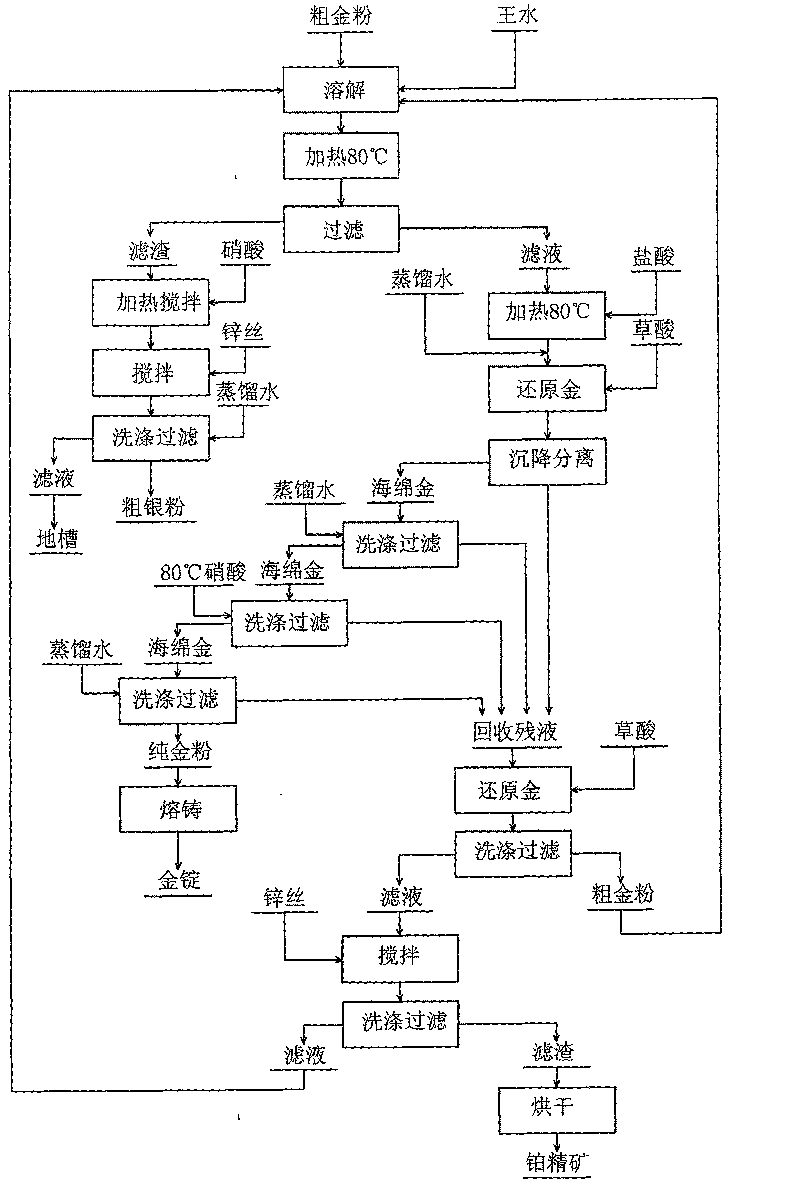

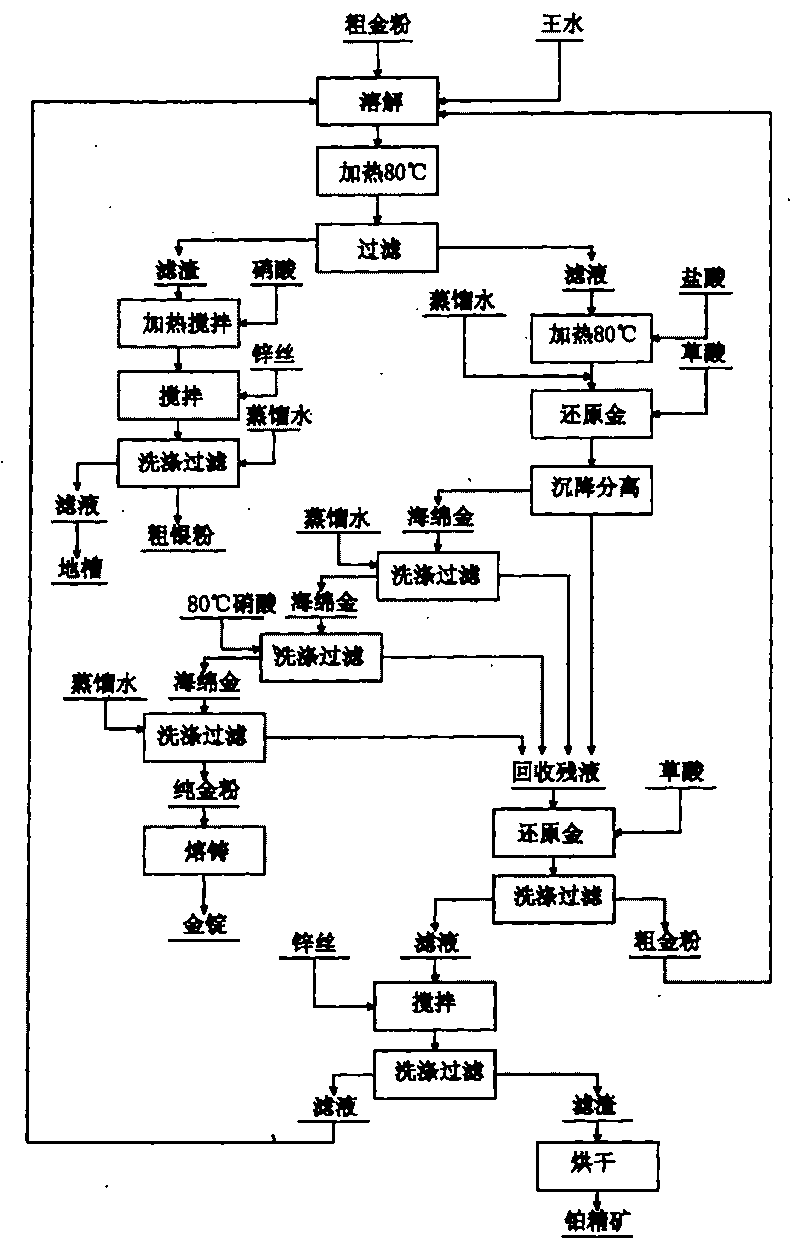

Gold wet purification process

The invention relates to a process for purifying gold by the wet method. Firstly, aqua fortis is used to remove silver; secondly, nitric acid is used to remove impurities such as bismuth and copper, etc.; the separation is performed by filtering; in the richly contained gold solution, the gold is reduced to gold powder deposited by an oxalic acid reducing agent with strong reducibility, and the impurities such as platinum, the bismuth and the copper, which are reduced simultaneously, are redissolved by nitric acid added later and enter the solution, and the solution is subjected to the filtering separation to obtain pure gold powder; and the pure gold powder is made to be ingot-shaped by fushion casting, and the finished gold ingots with a gold content of 99.99 percent are obtained. In the invention, the reduction reaction is made by oxalic acid at a low temperature, so that the process of the invention has the advantages of not causing environmental pollution, favorability for the heath of operators, lowering cost, shortening the period and obvious economic and social benefits.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

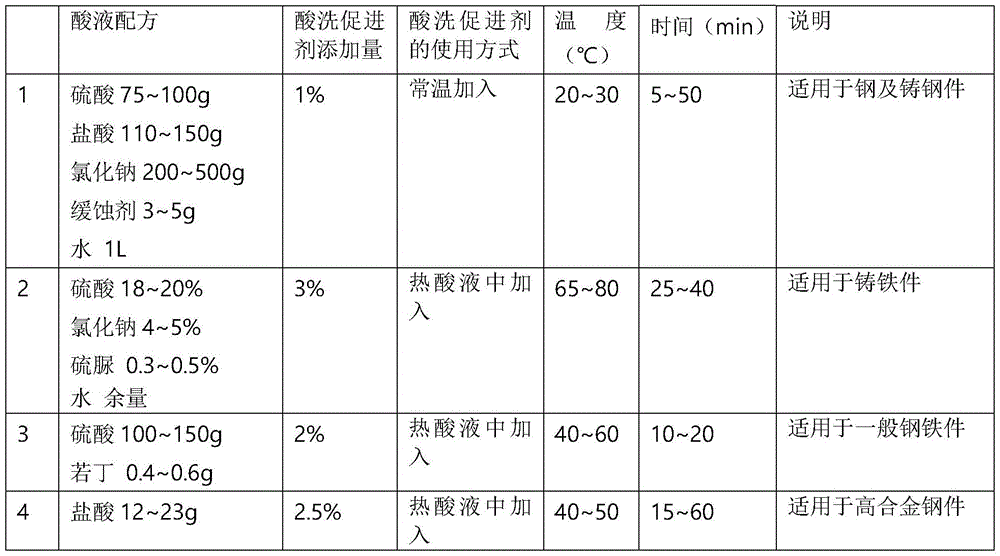

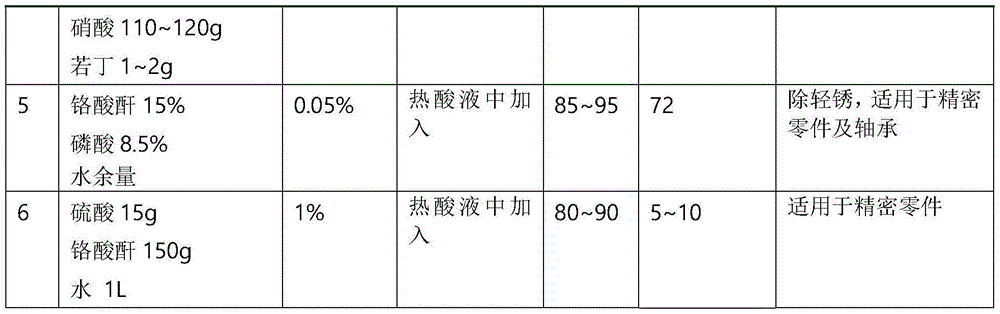

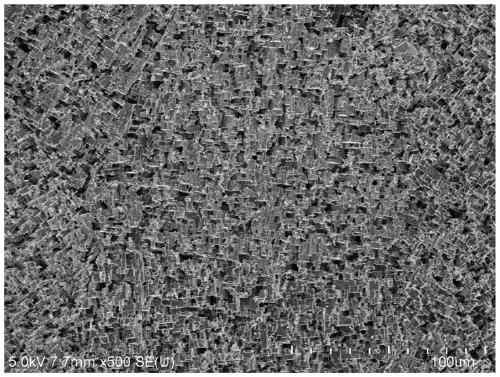

Acid-washing method for common carbon steel/semi-process electrical steel with thickness of 3.0-6.0mm

The invention discloses an acid-washing method for common carbon steel / semi-process electrical steel with thickness of 3.0-6.0mm. The acid-washing method comprises the following steps of: adding acid-washing accelerator into a hydrochloric acid acid-washing solution when the concentration of free acid in the hydrochloric acid acid-washing solution is reduced from 180-200g / L to 110-120g / L and the concentration of Fe<2+> is increased to 50-70g / L; controlling a volume ratio of acid-washing accelerator to hydrochloric acid acid-washing solution to be (0.4-0.6):100; and after acid-washing for 40-70 seconds under the temperature of 80-85 DEG C, rinsing with hot water. The acid-washing accelerator is composed of surface active agent, organic complexing chelant, corrosion inhibitor, reducing agent and stabilizing agent, wherein the concentration of the surface active agent is 5-10g / L; the concentration of the organic complexing chelant is 20-40g / L; the concentration of the corrosion inhibitor is 10-20g / L; the concentration of the reducing agent is 20-30g / L; and the concentration of the stabilizing agent is 10-15g / L. The surface scale of the common carbon steel / semi-process electrical steel is eliminated by using the hydrochloric acid acid-washing solution mixed with the acid-washing accelerator, the acid-washing speed is increased by above 35% and the surface quality is similar to the effect by using the imported acid-washing accelerator.

Owner:湖南华菱涟源钢铁有限公司 +1

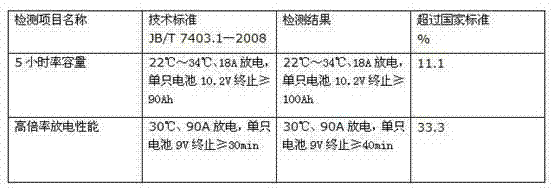

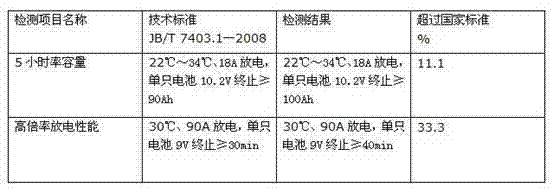

Inner forming process of tubular lead-acid storage battery

ActiveCN102347516AShorten the production cycleEliminate tedious workFinal product manufactureSecondary cells charging/dischargingElectrical batteryPhysical chemistry

The invention discloses an inner forming process of a tubular lead-acid storage battery, which comprises the following steps of: (1) assembling positive and negative raw polar plates into a battery shell, filling 1.23-1.25g / cm<3> of sulfuric acid solution and standing for an hour so that the polar plates are fully soaked in the acid liquor; and (2) dividing the whole inner forming process into three phases, wherein different charging and discharging currents and time are adopted in different phases. The inner forming process lasts for four days, thereby shortening the production period, omitting the cockamamie sections, such as discharge, water washing, drying, and the like after formation and saving the production cost. Meanwhile, the polar plates are formed in the battery shell in the production process, and therefore, the acid mist is less, the pollution is low, and the body damage to workers is less than that of outer formation.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU NEW ENERGY

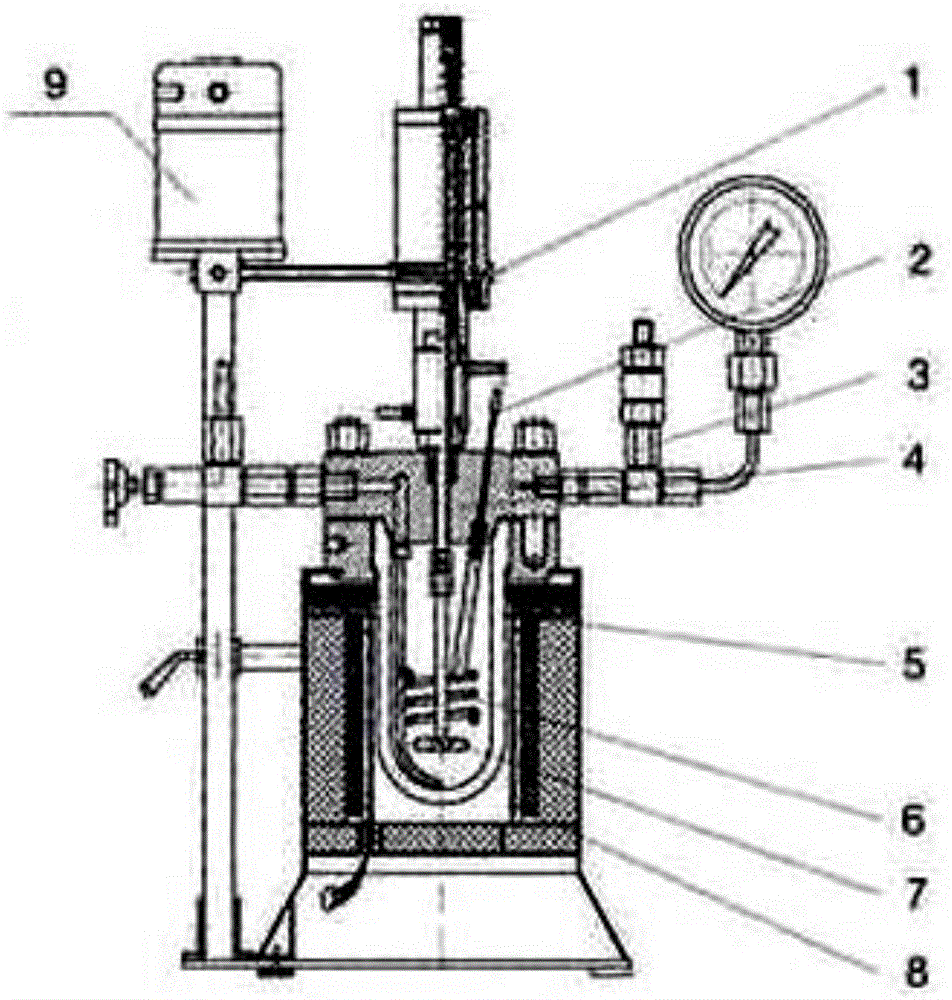

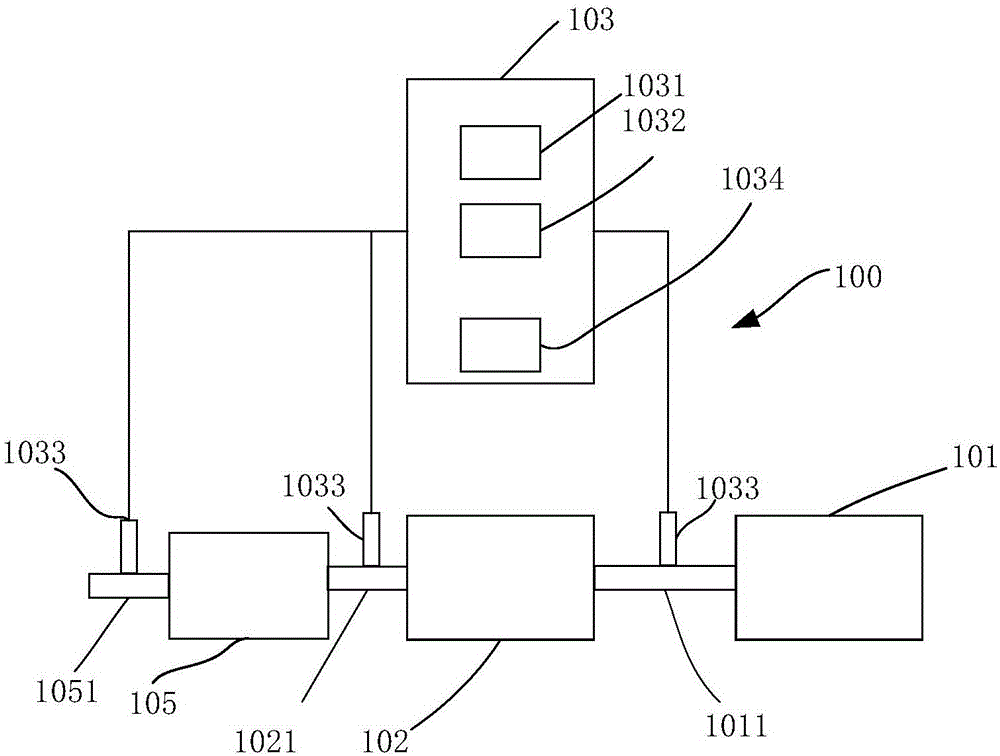

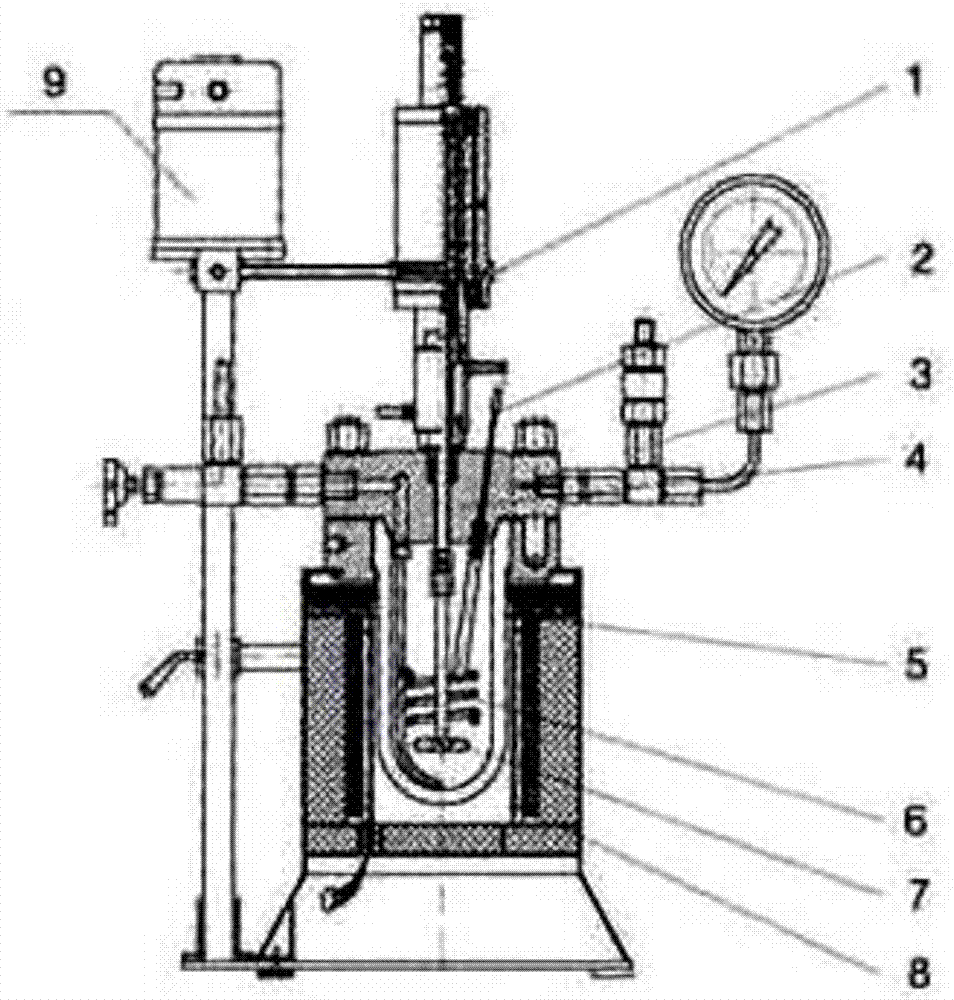

Liquid calcium/zinc heat stabilizer, preparing method thereof and device for implementing method

ActiveCN105111620AProduction safety and environmental protectionTakes a long timeCalcium hydroxideZinc hydroxide

The invention discloses a liquid calcium / zinc heat stabilizer. The liquid calcium / zinc heat stabilizer comprises, by weight, 10 parts to 15 parts of calcium oxide and / or calcium hydroxide, 10 parts to 20 parts of zinc oxide and / or zinc hydroxide, 30 parts to 40 parts of acid liquor, 1 part to 2 parts of azeotropic agents, 10 parts to 20 parts of saturated cycloparaffin solvents and 10 parts to 20 parts of heat-proof assistants. The invention further discloses a preparing method of the liquid calcium / zinc heat stabilizer and a device for implementing the method. According to the liquid calcium / zinc heat stabilizer, the product performance is stable, floccule can not be separated out during placing, the product is free of pungent smells, and the body of an operator can not be hurt. The preparing method of the liquid calcium / zinc heat stabilizer adopts a one-step method, the production technology is simplified, the unsafe factors in the production process are reduced, the production efficiency is improved, and the output rate is increased.

Owner:GUANGZHOU YINGSU NEW MATERIAL TECH CO LTD

Novel steel pipe rust remover and preparation method thereof

The invention provides a novel steel pipe rust remover and a preparation method thereof, and relates to the technical field of metal surface conditioning agents. The rust remover comprises 18-23wt% of hydrochloric acid, 8-13wt% of oxalic acid, 1.8-2.3wt% of a corrosion inhibitor, 1.8-2.3wt% of EDTA, 1.8-2.3wt% of citric acid, 0.25-0.35wt% of an osmotic agent JFC, and the balance of water. The corrosion inhibitor is prepared by compounding urotropine, rosinyl imidazoline ammonium salt and industrial alcohol according to a weight ratio of 3:0.8:5. The novel steel pipe rust remover provided by the invention generates obviously less acid mist than simple acid solutions for rust removal in the prior art in the use process, and the replacement frequency of the rust remover is only 1 / 3 of that of the acid solutions under a same use frequency, so the acid waste is greatly reduced; and almost no steel pipe over-etching conditions appear in the production process, so the production cost of steel pipe enterprises is greatly reduced.

Owner:HUNAN JINHUA SCI & TECH GRP

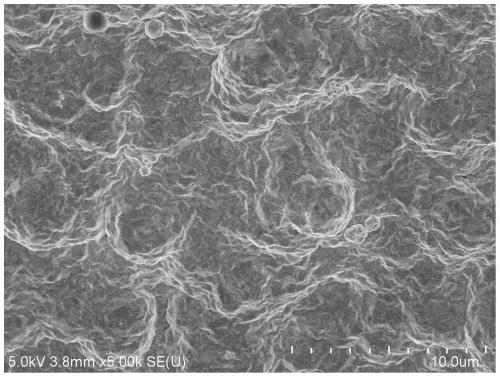

Silicon steel pickling promoter and preparation method thereof

The invention specifically relates to a silicon steel pickling promoter and a preparation method thereof. According to a technical scheme in the invention, the silicon steel pickling promoter is prepared from 0.1 to 5.0 wt% of a corrosion inhibitor, 10.0 to 50.0 wt% of an inorganic salt reducing agent, 0.1 to 5.0 wt% of an emulsifier, 5.0 to 20.0 wt% of an organic metal ion chelating agent, 0.1 to 5.0 wt% of a defoaming agent, 0.1 to 5.0 wt% of a synergist and 20.0 to 80.0 wt% of water through uniform mixing at normal temperature with stirring. The silicon steel pickling promoter provided by the invention has the characteristics of convenience in usage, high pickling efficiency, low cost, environment friendliness, a good corrosion inhibition effect, etc.

Owner:WUHAN UNIV OF SCI & TECH

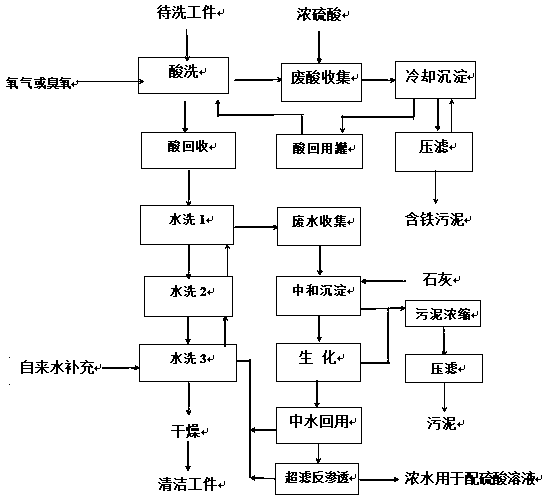

Steel pickling and water recycling method

InactiveCN109735850AIncrease productivityAvoid hanging dustMetallic material coating processesMetallurgyCarbon steel

The invention discloses the field of carbon steel surface pickling and stainless steel pickling passivation, and provides a steel pickling and water recycling method. The method solves the problems that in the production process, a large amount of acid mist is generated, the workpiece rising water treatment difficulty is large, during achieving, water recycling investment and running cost are high, and waste acid recycling is difficult. The steel pickling and water recycling method can be used for acid pickling of carbon steel and also can be used for stainless steel pickling passivation, waste acid recycling is achieved whole rinsing water is circularly used with low cost, and on the basis of ensuring production efficiency and product quality, the environment risk is greatly reduced.

Owner:南京馥安投资管理有限公司

Metal rust remover and preparation method thereof

The invention discloses a metal rust remover and a preparation method thereof, and aims to provide the rust remover which is capable of removing rusts on the surface of a metal and is simple in preparation method. According to the technical scheme, 1L of metal rust remover contains the following components: 150g to 250g of acid, 120g to 200g of oxalic acid, 100g to 150g of carbonate, 20g to 50g of fatty alcohol-polyoxyethylene ether, 3g to 7g of alkylphenol ethoxylates, 5g to 10g of thiourea, 20g to 40g of ethylene diamine tetraacetic acid, 10g to 20g of urotropin and the balance of water. The preparation method comprises the following steps: 1) weighing the components; 2) putting the components weighed by the step 1) in a flask, adding water to reach 1L and then stirring at a room temperature for 5 to 10 minutes so as to obtain the metal rust remover. The metal rust remover belongs to the technical field of metal cleaning.

Owner:WUZHOU HENGSHENG ELECTRONICS

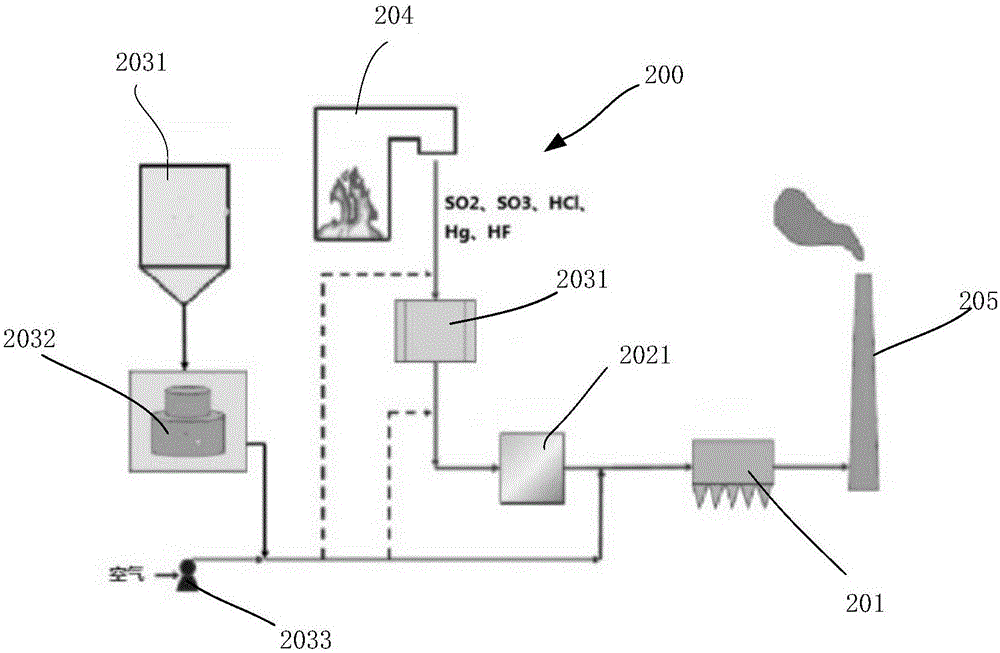

Dust removing device and flue gas dust removing method

InactiveCN106179739AReduce contentLess acid mistElectrostatic separationDispersed particle separationFlue-gas stackChiller

The invention relates to a dust removing device which comprises an electric precipitator, a cooler and an alkalinity absorbent injection system, wherein the cooler and the alkalinity absorbent injection system are connected with an inlet section of the electric precipitator. An injection nozzle of the alkalinity absorbent injection system is formed in an inlet section of the cooler. The invention further relates to a flue gas dust removing method. The flue gas dust removing method comprises the steps of injecting an alkalinity absorbent to flue gas, cooling the flue gas and removing dust of the cooled flue gas. By adoption of the technical scheme of the embodiment of the invention, the SO3 content in the flue gas is effectively decreased, acid mist generated by the cooled flue gas is reduced, and the situation that blocking objects are formed by attaching of the acid mist and dust, and consequently failure of subsequent equipment such as dust removing equipment is caused is reduced. Further, the acid content in the flue gas is decreased, and the corrosion effect of acid on the equipment is effectively controlled accordingly.

Owner:CHINA HUADIAN ENG +1

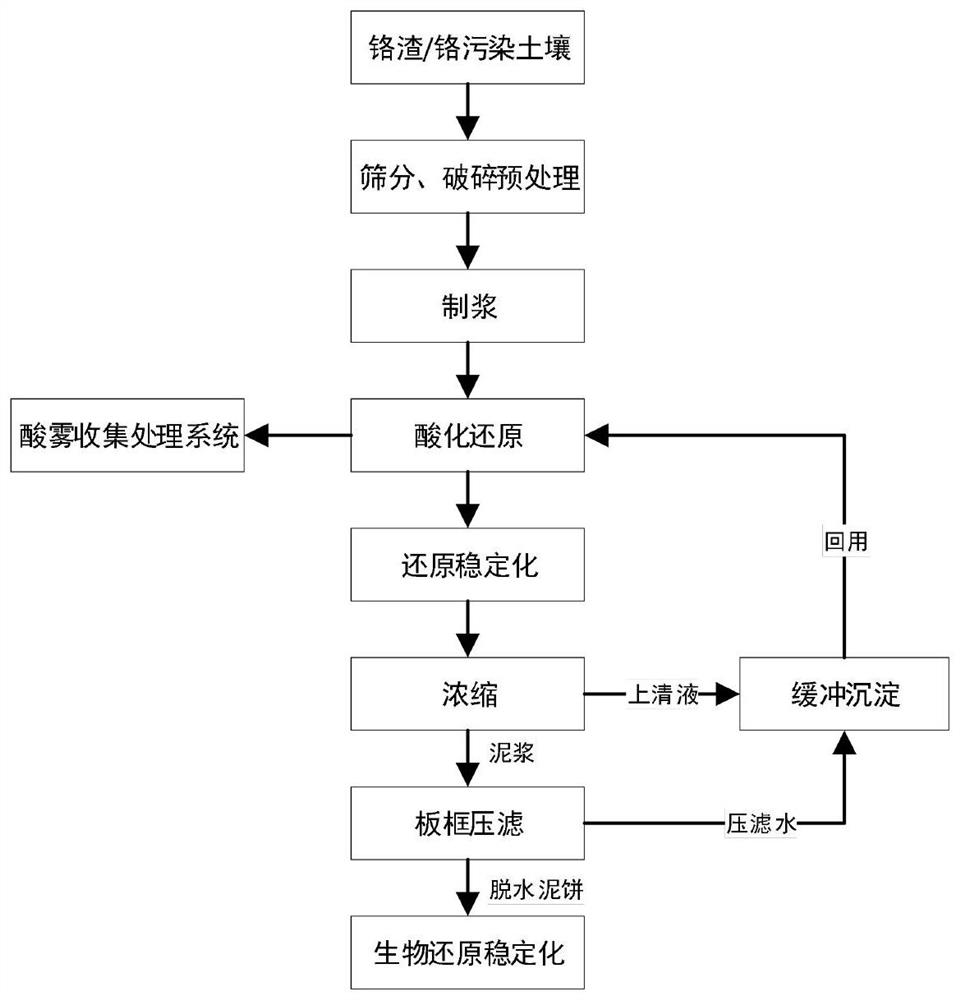

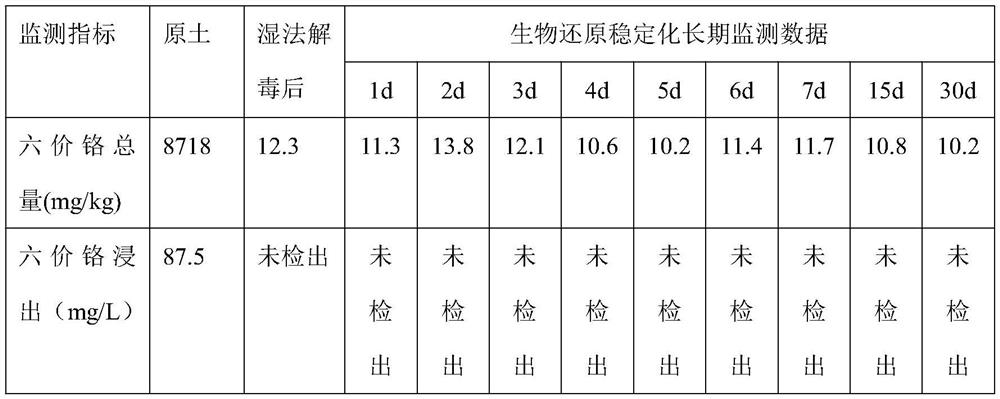

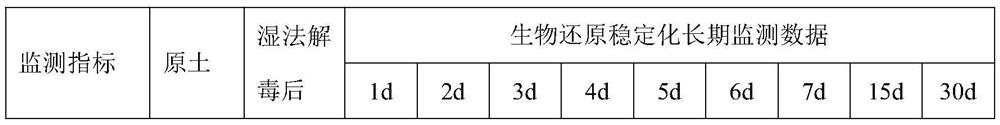

Wet detoxification and bioremediation combined method for chromium slag and chromium-contaminated soil

InactiveCN113751488AReduce generationPromote dissolutionContaminated soil reclamationOrganic fertilisersCarboxylic acidSlurry

The invention discloses a wet detoxification and bioremediation combined method for chromium slag and chromium-contaminated soil, wherein the method comprises the steps: pretreating waste slag containing hexavalent chromium or chromium-contaminated soil, removing large-particle materials, and conveying to a slurry stirring tank to obtain chromium-containing slurry; conveying the slurry to a wet detoxification acidification reduction tank, adding concentrated sulfuric acid, organic acid, hydroxy carboxylate and ferrous sulfate, carrying out acidification reduction reaction, dissolving out hexavalent chromium, and reducing hexavalent chromium into trivalent chromium; and then enabling the slurry to enter a reduction and stabilization tank, adding a reduction and stabilization agent for further reduction and stabilization reaction, and fully reacting hexavalent chromium to generate a stable trivalent chromium complex; then carrying out solid-liquid separation on the slurry, wherein filtrate flows into a wet detoxification reaction tank for recycling; and further carrying out biological reduction stabilizing treatment on dewatered cement cake, so as to ensure the long-term stability of the treated material.

Owner:湖南新九方科技有限公司

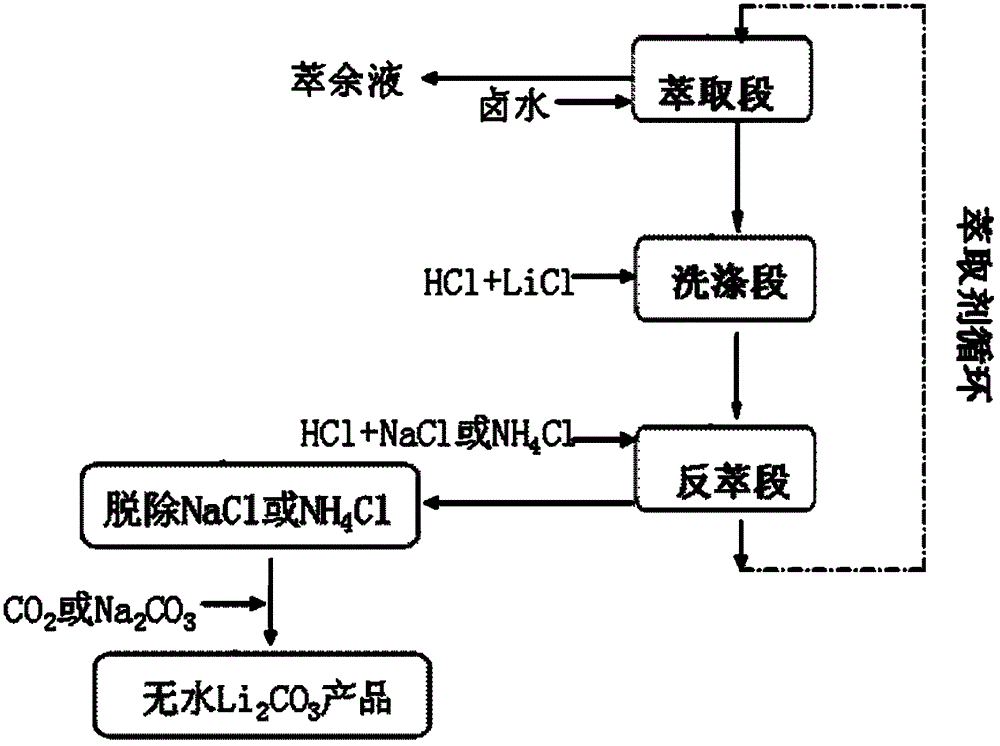

Method for extracting lithium carbonate from salt lake brine with high magnesium/lithium ratio

InactiveCN102275956BReduce lossesNo decrease in recycling efficiencyNanotechnologyLithium carbonates/bicarbonatesInorganic saltsHigh magnesium

The invention discloses a method for extracting lithium carbonate from salt lake brine with high magnesium / lithium ratio, belonging to the technical filed of inorganic salt extraction. The method comprises the following steps of: carrying out extraction, washing and stripping steps to obtain a stripping solution composed of NaCl and LiCl or NH4Cl and LiCl, then introducing CO2 or adding Na2CO3, and controlling the pH value and dynamic conditions to obtain a nanoscale or microscale Li2CO3 product. The method disclosed by the invention has the advantages of simple steps, low equipment requirement and wide sources of raw materials, and is suitable for industrial production.

Owner:TSINGHUA UNIV

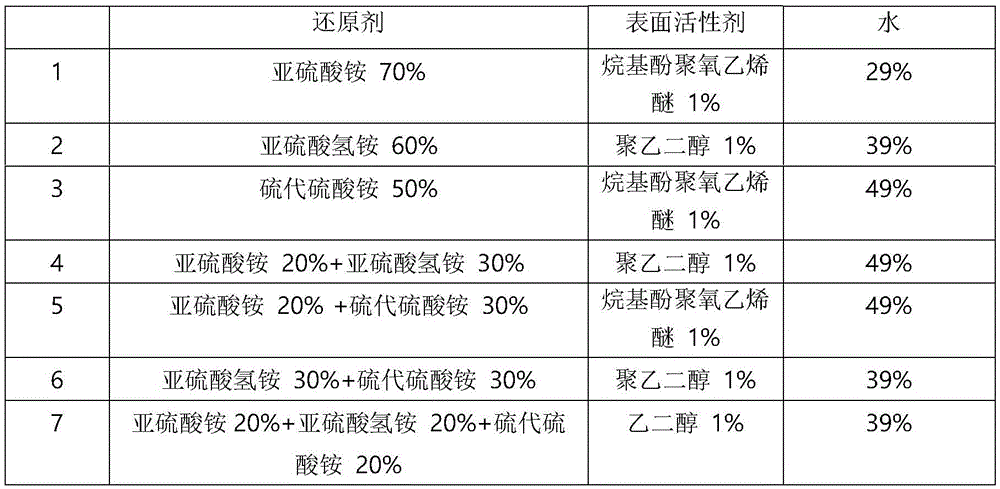

Steel acid pickling accelerant not containing metal elements and application method of steel acid pickling accelerant

ActiveCN105568301AIncrease pickling speedIncrease production capacitySurface-active agentsMetallurgy

The invention provides an efficient steel acid pickling accelerant not containing metal elements. The steel acid pickling accelerant is composed of a reducing agent and a surface active agent. The steel acid pickling speed can be greatly increased or the acid pickling temperature can be reduced as long as a small number of accelerants are added, and therefore the purposes of improving productivity, reducing acid mist, saving energy and reducing emission are achieved.

Owner:SUZHOU CANASTAR NEW MATERIALS TECH CORP

Cold-rolling acid-pickling corrosion inhibitor and preparation method thereof

The invention discloses a cold-rolling acid-pickling corrosion inhibitor. The cold-rolling acid-pickling corrosion inhibitor is prepared by sequentially performing condensation reaction and constant-temperature stirring reaction on vitamin B3 and organic amine in a molar ratio of (1.5 to 1) to (1 to 1.5), performing distillation and removing a solvent, wherein the carbon number of the organic amine is 8 to 16. According to the cold-rolling acid-pickling corrosion inhibitor disclosed by the invention, reaction between the vitamin B3 and the organic amine is carried out so as to synthesize a novel corrosion inhibitor for the first time, and the organic amine is applied to the processes including cold rolling and acid pickling and the like, so that the advantages of less consumption, high corrosion inhibition efficiency and the like are achieved, the surface quality of steel plates subjected to acid pickling can be effectively promoted, quality defects such as no black spots and darkeningare avoided, and a brand new means is provided for a high-efficient clear process; moreover, the preparation method disclosed by the invention is simple, the cost is low, and the cold-rolling acid-pickling corrosion inhibitor has important popularization and application value.

Owner:武汉钢铁有限公司

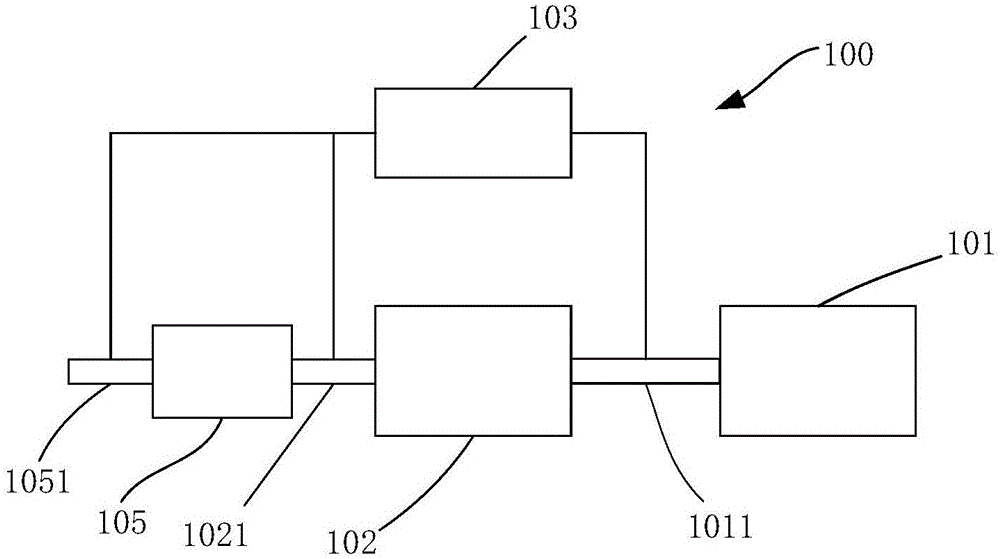

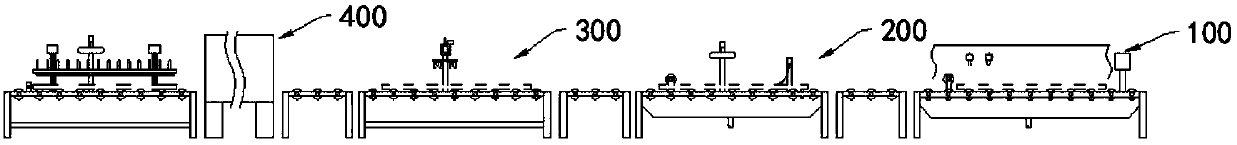

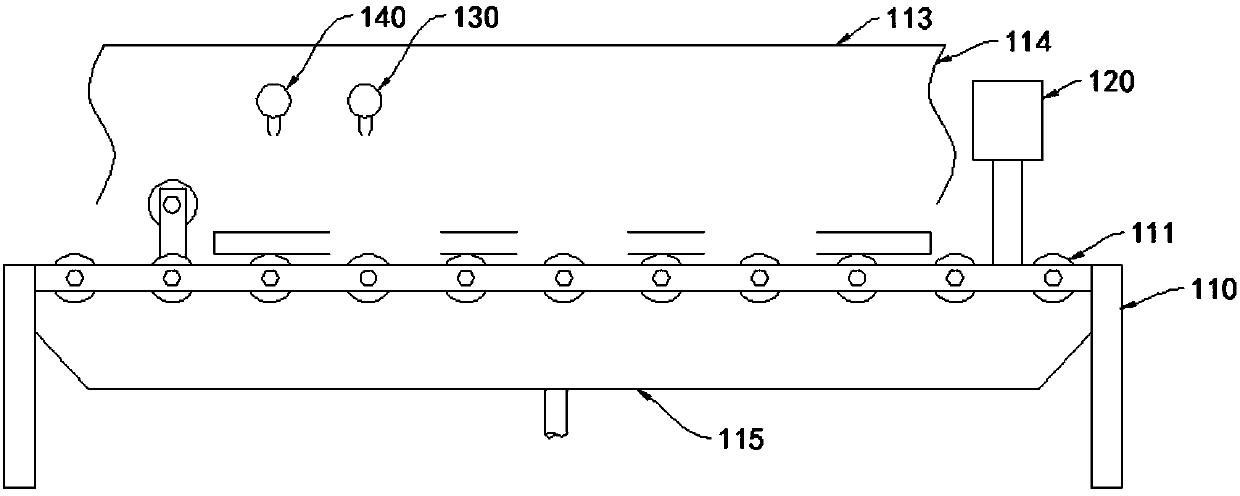

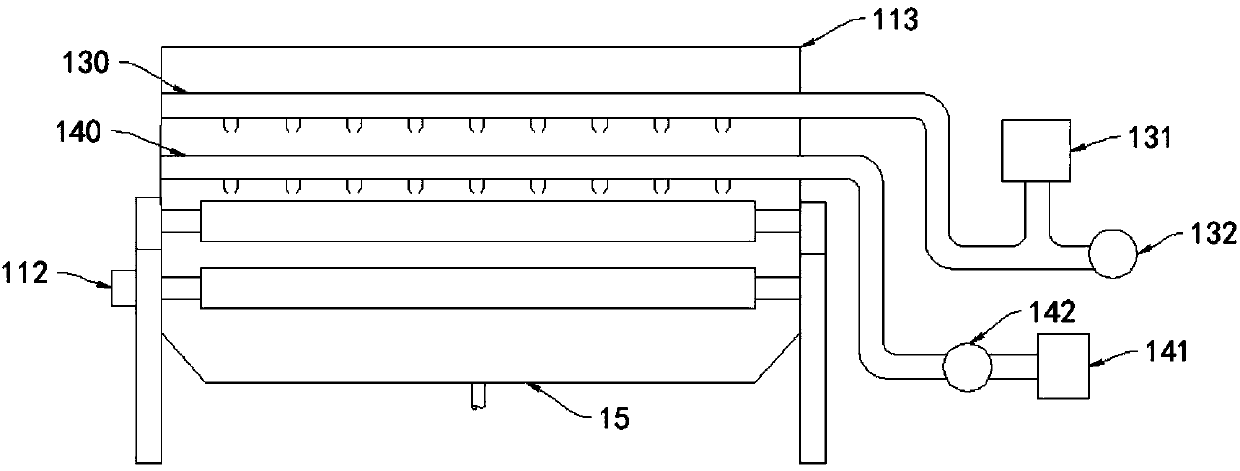

Blackboard panel production system

InactiveCN107774480ATurn down the spray pressureReduce usageSpraying apparatusPretreated surfacesSheet steelEngineering

The invention discloses a blackboard panel production system, which comprises a cleaning device, an air-drying device and a spraying device arranged in sequence; the cleaning device sprays acid liquid and also sprinkles sand on the steel plate surface; the air-drying device is provided with a scraping curtain and a scraper; the roller set of the spraying device includes ordinary rollers and magnetic rollers arranged at intervals, and a baffle is provided at the spray head; the post-processing device is covered by a cooling plate and contacts the steel plate for heat conduction, and at the same time uses a fan to dissipate heat. The invention has the problems of various cleaning methods, good air-drying effect and spraying effect, and high cooling efficiency.

Owner:湖州逸邦贸易有限公司

Preparation method and using method of rust remover for electromechanical equipment

The invention provides a preparation method and using method of a rust remover for electromechanical equipment. The preparation method comprises the following steps of: mixing a condensation compound of alkyl phenol and epoxyethane with a weakly alkaline sodium salt, thiourea, sulfamic acid and organic weak acid, and stirring after adding water so as to fully dissolve all the components in the water. The using method comprises the following steps of: cleaning the electromechanical equipment by using gasoline or acetone so as to remove oil, immersing the cleaned electromechanical equipment without oil into the prepared dust remover solution for 20-40 minutes at a normal temperature, washing the electromechanical equipment by using running water for 4-8 minutes immediately after taking out the electromechanical equipment from the dust remover solution, then immersing the electromechanical equipment into a sodium carbonate aqueous solution for 10-25 minutes, taking out the electromechanical equipment, washing the electromechanical equipment by using running water and wiping the electromechanical equipment dry. The rust remover is simple in the preparation technology and has no influence on the surface of the electromechanical equipment; the surface of the electromechanical equipment is relatively bright after rust on the surface of the electromechanical equipment is removed by using the rust remover; the rust remover has a good rust removal effect, is low in cost, can be used at a normal temperature, is less likely to generate acid mist, is harmless to human bodies and environmentally-friendly, and does not damage the surface of the electromechanical equipment; and the preparation method and using method of the rust remover are simple in operation.

Owner:合肥市闵葵电力工程有限公司

A kind of rust remover and preparation method thereof

Owner:HUNAN JINHUA SCI & TECH GRP

Pickling solution for stability of rust layer of bare steel

InactiveCN104805457AAvoid corrosionAvoid hydrogen embrittlementMetallic material coating processesHexamethylenetetramineThiourea

The invention discloses pickling solution for stability of a rust layer of bare steel. The pickling solution comprises the following components in percentage by weight: 2 to 18 percent of HCl, 1 to 10 percent of H3PO4, 0.5 to 5 percent of HNO3, 1 to 10 percent of thiourea, 0.1 to 5 percent of hexamethylenetetramine, 0.1 to 5 percent of carboxyl cellulose salt and the balance of water. The pickling solution can be used for directly pickling a hot rolled plate in a range of 60 to 90 DEG C; a small quantity of acid mist is generated under the high temperature condition; the over etching and hydrogen embrittlement phenomena of a workpiece also can be avoided; product quality is improved.

Owner:武汉钢铁有限公司

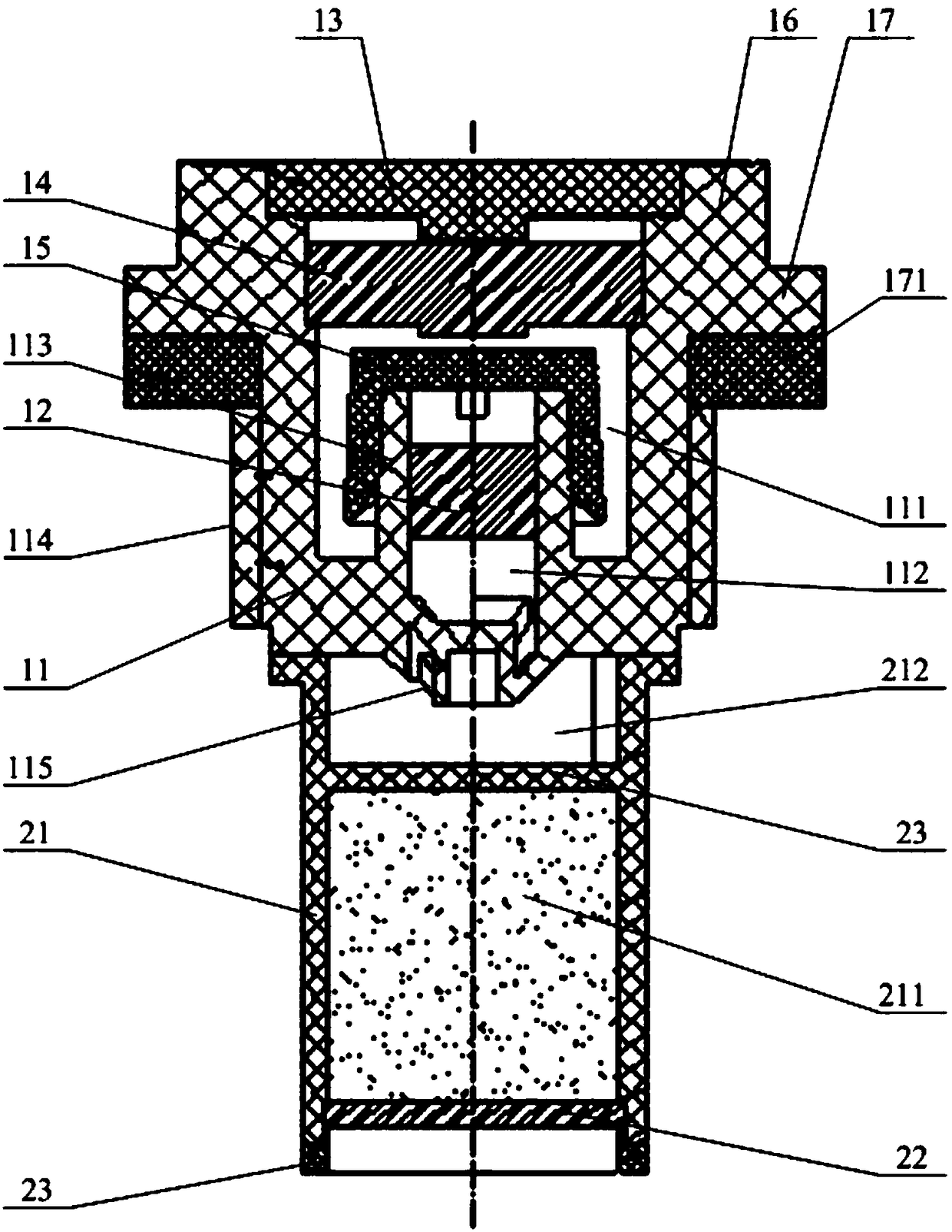

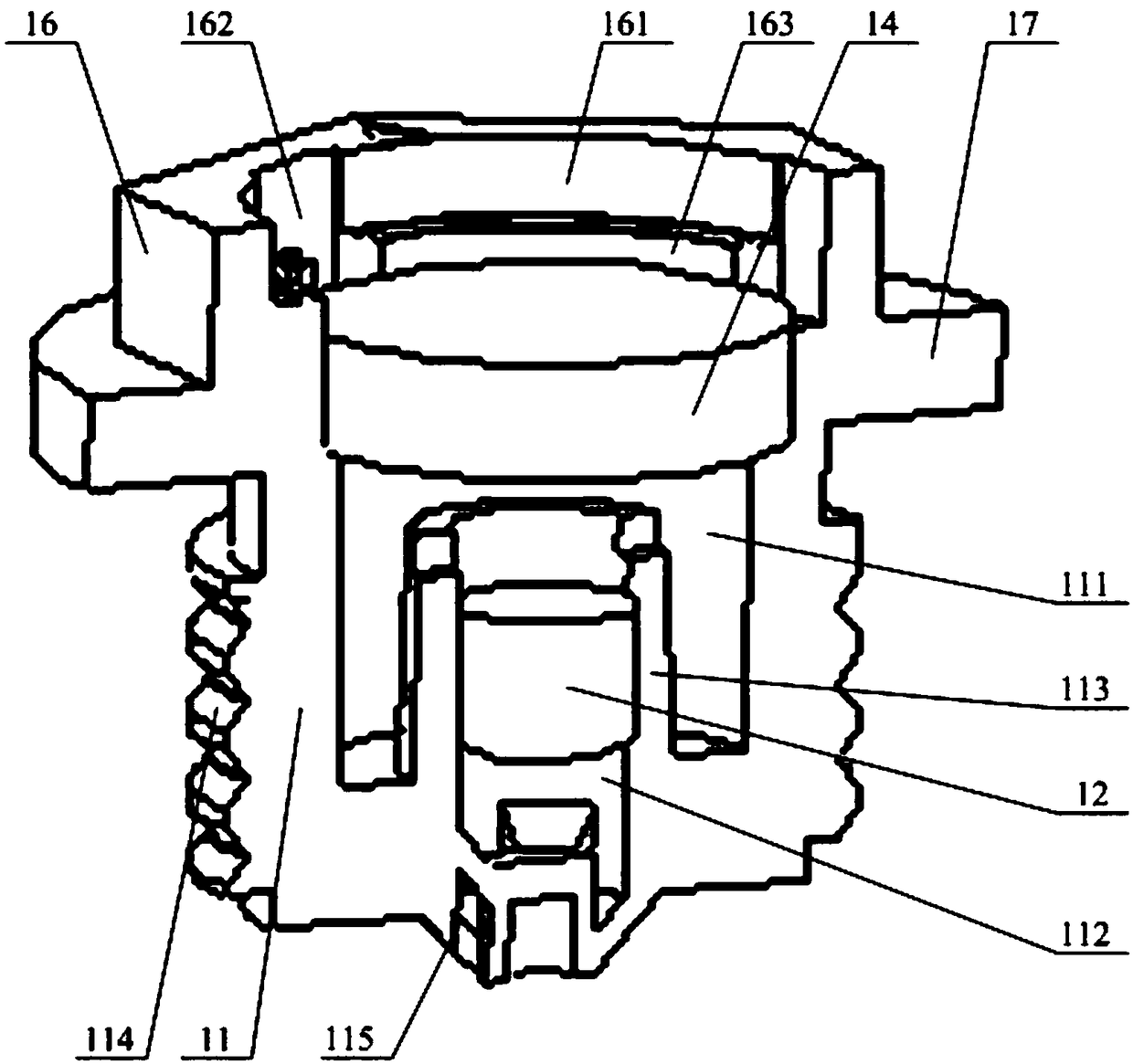

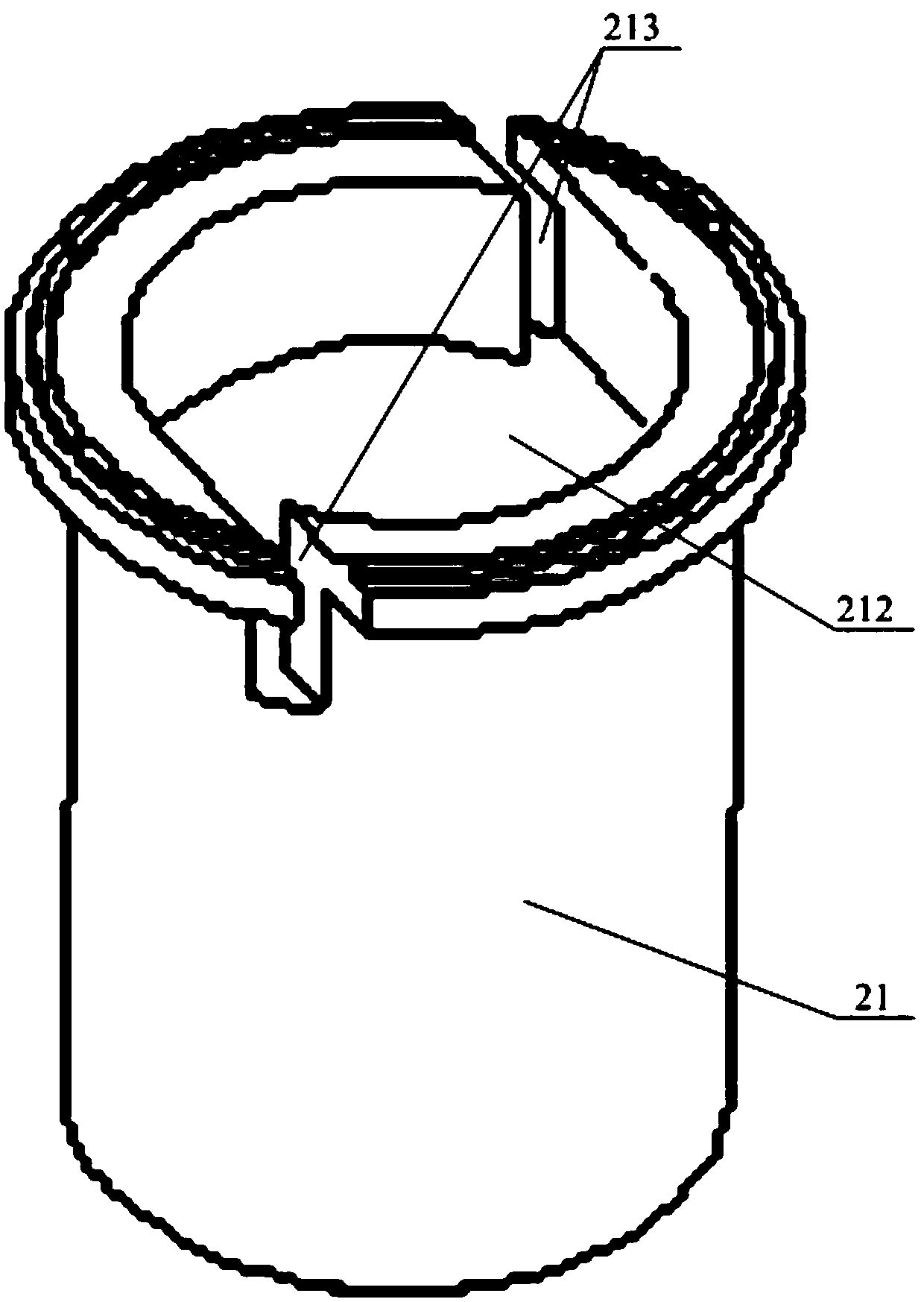

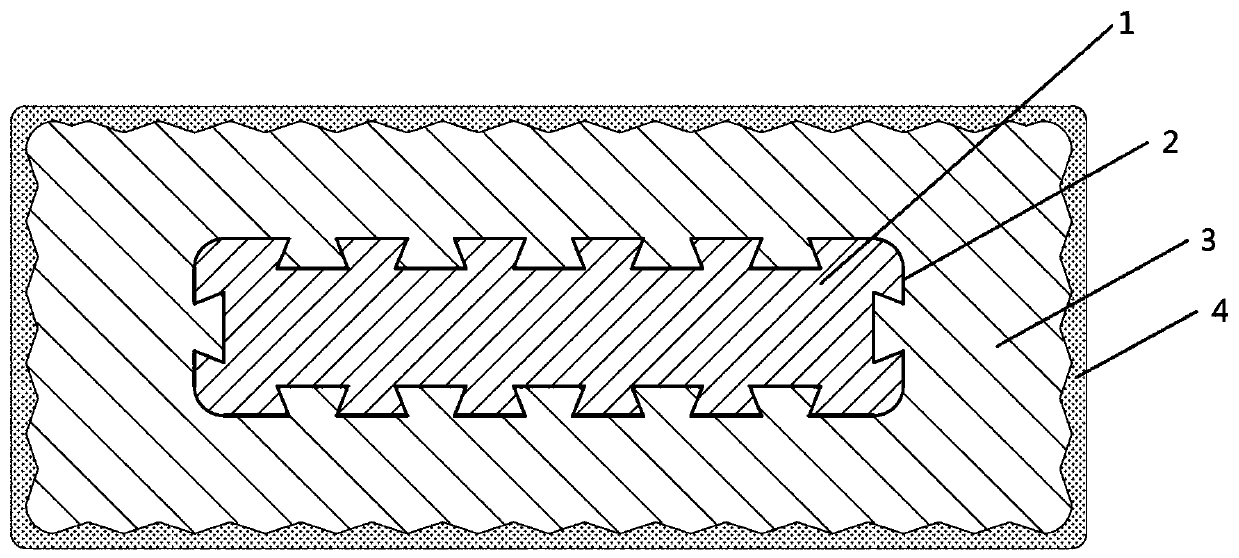

Lead-acid storage battery and exhaust valve assembly

PendingCN108550761AGuaranteed machining accuracyGuaranteed structural strengthFinal product manufactureVent arrangementsExhaust valveMechanical engineering

The invention discloses an exhaust valve assembly which comprises a valve body arranged at the top of a storage battery shell and a plug body positioned in an inner cavity of a storage battery and connected to the bottom of the valve body. A reaction cavity which can accommodate a catalyst and is communicated with the inner cavity of the storage battery is formed at the middle part of the plug body; a lower acid filtering sheet is arranged at the bottom of the reaction cavity; a valve cavity is formed inside the valve body; an air passage communicated with the inner cavity of the storage battery is formed at the bottom of the valve cavity; a middle acid filtering sheet is arranged at the middle part of the air passage; a cover plate is arranged at the top of the valve cavity; an upper acidfiltering sheet is arranged between the cover plate and the middle acid filtering sheet; and the valve body is provided with an exhaust port for communicating the valve cavity with the external environment. The exhaust valve assembly is high in machining accuracy and can effectively reduce water loss and an acid mist discharge rate of a lead-acid storage battery in the working process. The invention further discloses a lead-acid storage battery applying the exhaust valve assembly.

Owner:SHANDONG SACRED SUN POWER SOURCES

Metal oil removal agent and preparation method thereof

The invention discloses a metal oil removal agent and a preparation method thereof and aims to provide an oil removal agent which can completely remove oil dirt on the metal surface at normal temperature and is environmentally friendly in formula. According to the technical key points, every liter of oil removal agent comprises the following components: 120-200g of oxalic acid, 100-150g of carbonate, 10-30g of fatty alcohol-polyoxyethylene ether, 2-5g of alkylphenol polyoxyethylene, 5-15g of thiourea, 20-40g of ethylene diamine tetraacetic acid and the balance of water. The method for preparing the metal oil removal agent comprises the following steps: (1) weighing each component; and (2) adding the components weighed in the step (1) into a flask, adding water to 1L, stirring at the temperature of 50-80 DEG C for 5-10 minutes, and obtaining the metal oil removal agent. The invention belongs to the technical field of metal cleaning.

Owner:WUZHOU HENGSHENG ELECTRONICS

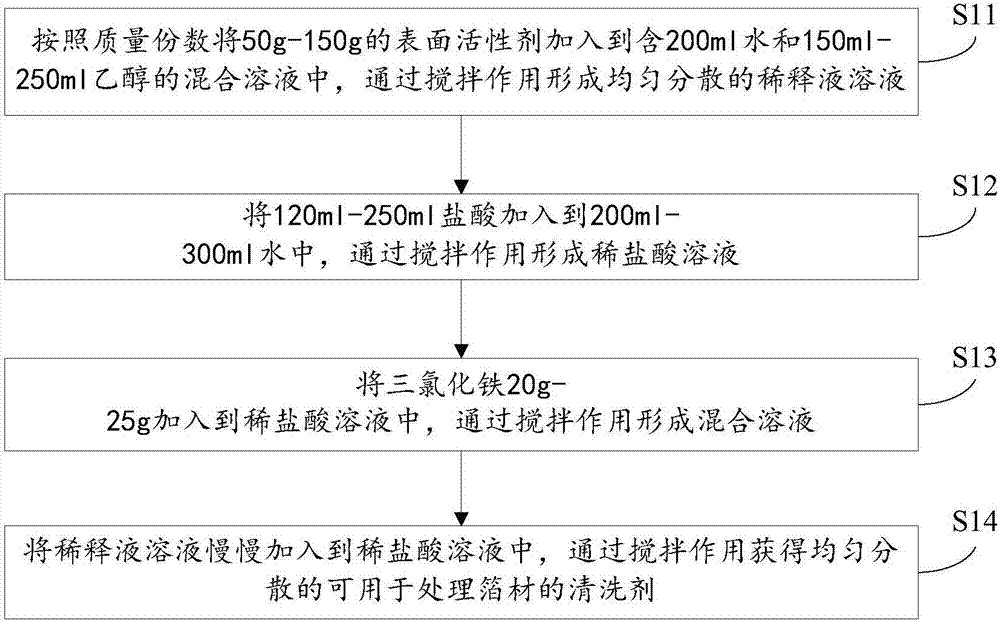

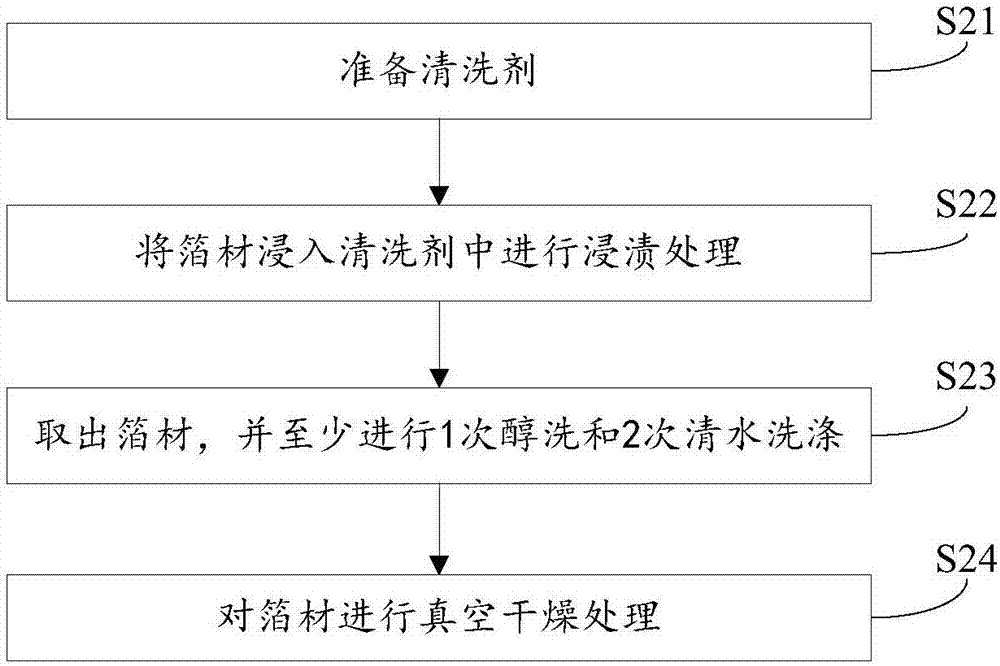

Cleaning agent for foil surface cleaning, preparation method of cleaning agent for foil surface cleaning and foil surface cleaning method

The invention discloses a cleaning agent for cleaning the surface of a foil, comprising: hydrochloric acid, a surfactant, ethanol and water; its components are configured according to the following parts, wherein the hydrochloric acid is: 120ml-20ml; the surfactant For: 50g‑150g; for ferric chloride: 20g‑25g; for ethanol: 150ml‑250ml; for water: 400ml‑500ml. The invention also discloses a preparation method and a cleaning method of a cleaning agent for cleaning the foil surface. Through the above embodiments, the oxide layer on the surface of the foil can be corroded and cleaned in a directional manner, the oil on the surface of the foil can be quickly removed, and an organic active area can be formed at a specific position on the surface of the foil, which can improve the bonding between the foil and the organic base adhesive Effect.

Owner:深圳市力合测控技术有限公司 +1

A kind of pickling solution containing compound passivating agent and preparation method thereof

The invention belongs to the field of cleaning stainless steel castings, and relates to a pickling solution with passivation effect obtained by adding organic substances to HNO3 and HF basic acid solution. It is composed of nitric acid and hydrofluoric acid, compound passivating agent and water, and its mass content is respectively: 3.3%~37.5% for nitric acid, 0.7%~7.5% for hydrofluoric acid, and 1.3~13.5% for compound passivating agent , Water is the balance. Clean the polluted stainless steel castings to restore the metallic luster of the castings. And a dense passivation film is formed on the surface of the casting, so that the casting can still keep silver bright and beautiful without rust spots after long-term storage. Another feature of the present invention is that the acid mist is very small, which is beneficial to environmental protection and the health of operators, the pickling amount is large, and the acid treatment cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of liquid barium/zinc thermal stabilizer, its preparation method and equipment for implementing the method

ActiveCN105218967BNo harmStable in natureChemical/physical/physico-chemical stationary reactorsZinc hydroxidePhysical chemistry

The invention discloses a liquid barium / zinc heat stabilizer. The liquid barium / zinc heat stabilizer comprises the following preparation raw materials in parts by weight: 20-30 parts of barium oxide and / or barium hydroxide, zinc oxide and / or Or 15-20 parts of zinc hydroxide, 30-40 parts of acid solution, 1-2 parts of water-carrying agent, 5-20 parts of saturated naphthenic solvent and 5-15 parts of heat-resistant additive, and the hydroxide of barium is anhydrous At least one of barium hydroxide, barium hydroxide monohydrate and barium hydroxide octahydrate. The invention also discloses a preparation method of the liquid barium / zinc heat stabilizer and equipment for implementing the method. The performance of the liquid barium / zinc heat stabilizer of the present invention is stable, the product has no pungent smell, and will not cause harm to the health of operators; the preparation method of the liquid barium / zinc heat stabilizer of the present invention adopts a one-step method, which simplifies production The technology reduces the unsafe factors in the production process and improves the production efficiency and output rate.

Owner:GUANGZHOU YINGSU NEW MATERIAL TECH CO LTD

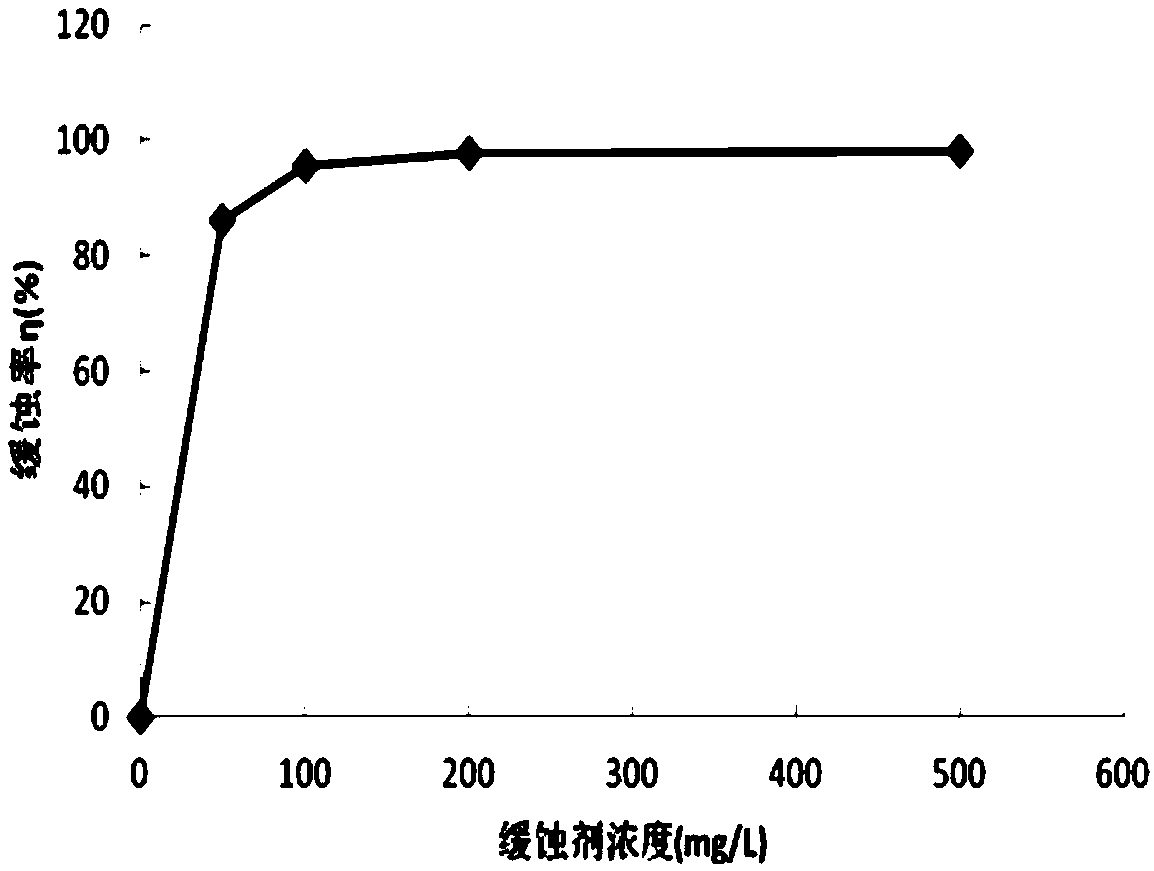

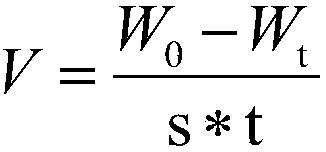

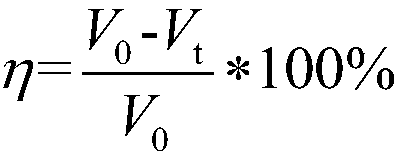

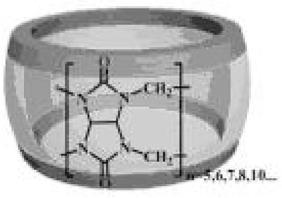

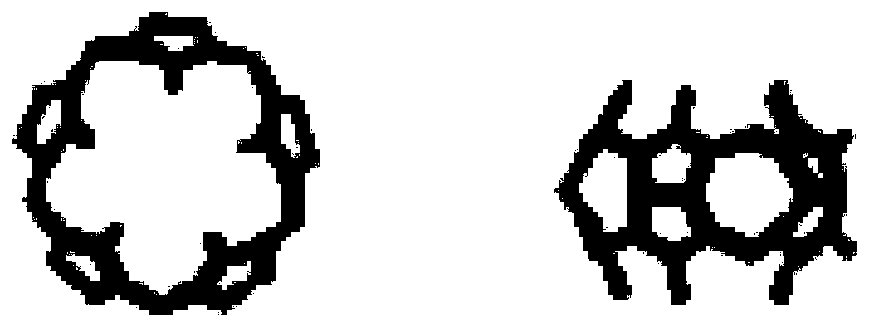

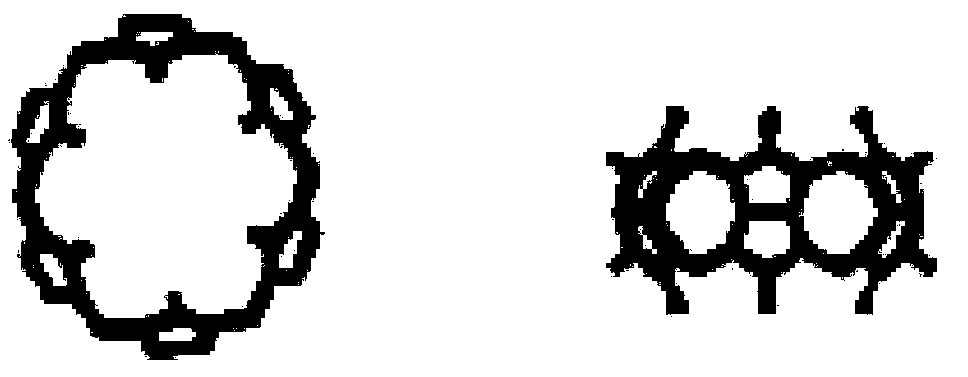

A kind of cucurbit compound type hydrochloric acid pickling corrosion inhibitor

The invention discloses a compound hydrochloric acid pickling corrosion inhibitor. The corrosion inhibitor is characterized by taking cucurbit[5]uril, cucurbit[6]uril, cucurbit[7]uril or cucurbit[8]uril as a main agent, being formed by compounding the main agent with one or more of triton, polyethylene glycol, cinnamaldehyde, 4-N,N-dimethylamino cinnamaldehyde, 3-(4-pyridyl)-acraldehyde, and being balanced with water.

Owner:GUIZHOU UNIV

Gold wet purification process

The invention relates to a process for purifying gold by the wet method. Firstly, aqua fortis is used to remove silver; secondly, nitric acid is used to remove impurities such as bismuth and copper, etc.; the separation is performed by filtering; in the richly contained gold solution, the gold is reduced to gold powder deposited by an oxalic acid reducing agent with strong reducibility, and the impurities such as platinum, the bismuth and the copper, which are reduced simultaneously, are redissolved by nitric acid added later and enter the solution, and the solution is subjected to the filtering separation to obtain pure gold powder; and the pure gold powder is made to be ingot-shaped by fushion casting, and the finished gold ingots with a gold content of 99.99 percent are obtained. In theinvention, the reduction reaction is made by oxalic acid at a low temperature, so that the process of the invention has the advantages of not causing environmental pollution, favorability for the heath of operators, lowering cost, shortening the period and obvious economic and social benefits.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Inner forming process of tubular lead-acid storage battery

ActiveCN102347516BShorten the production cycleEliminate tedious workFinal product manufactureSecondary cells charging/dischargingElectrical batteryPhysical chemistry

The invention discloses an inner forming process of a tubular lead-acid storage battery, which comprises the following steps of: (1) assembling positive and negative raw polar plates into a battery shell, filling 1.23-1.25g / cm<3> of sulfuric acid solution and standing for an hour so that the polar plates are fully soaked in the acid liquor; and (2) dividing the whole inner forming process into three phases, wherein different charging and discharging currents and time are adopted in different phases. The inner forming process lasts for four days, thereby shortening the production period, omitting the cockamamie sections, such as discharge, water washing, drying, and the like after formation and saving the production cost. Meanwhile, the polar plates are formed in the battery shell in the production process, and therefore, the acid mist is less, the pollution is low, and the body damage to workers is less than that of outer formation.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU NEW ENERGY

Surface-coated composite anode of porous aluminum rod and lead alloy for zinc electrodeposition and preparation method thereof

ActiveCN108754546BIncrease contact areaImprove conductivityAnodisationPhotography auxillary processesNanostructured carbonActive layer

The invention provides a porous aluminum bar lead alloy surface-coated composite anode applied to zinc electrodeposition and a preparation method thereof. The composite anode is composed of a substrate aluminum bar (1), a reinforcement layer coating the substrate aluminum bar and a surface active layer (4) coating the reinforcement layer, wherein the reinforcement layer comprises a bottom layer (2) and an intermediate layer (3); the bottom layer is a Pb / Ag metal composite layer; the intermediate layer is a lead alloy layer; the surface active layer is a composite manganese dioxide layer containing nano-tungsten carbide; the mass percentage of tungsten carbide in the surface active layer is 0.6-2.4wt.%. The prepared surface-coated composite anode is applied to zinc electrodeposition; compared with the conventional lead-silver alloy anode, the bath voltage is reduced by 120-240mV; the porous aluminum bar lead alloy surface-coated composite anode is long in service life and low in cost; the current efficiency is improved by 2-4%.

Owner:KUNMING UNIV OF SCI & TECH +2

Novel steel pipe rust remover and preparation method thereof

The invention provides a novel steel pipe rust remover and a preparation method thereof, and relates to the technical field of metal surface conditioning agents. The rust remover comprises 18-23wt% of hydrochloric acid, 8-13wt% of oxalic acid, 1.8-2.3wt% of a corrosion inhibitor, 1.8-2.3wt% of EDTA, 1.8-2.3wt% of citric acid, 0.25-0.35wt% of an osmotic agent JFC, and the balance of water. The corrosion inhibitor is prepared by compounding urotropine, rosinyl imidazoline ammonium salt and industrial alcohol according to a weight ratio of 3:0.8:5. The novel steel pipe rust remover provided by the invention generates obviously less acid mist than simple acid solutions for rust removal in the prior art in the use process, and the replacement frequency of the rust remover is only 1 / 3 of that of the acid solutions under a same use frequency, so the acid waste is greatly reduced; and almost no steel pipe over-etching conditions appear in the production process, so the production cost of steel pipe enterprises is greatly reduced.

Owner:HUNAN JINHUA SCI & TECH GRP

Steel and iron surface phosphating agent and preparation method thereof

InactiveCN105200414AImprove the workshop production environmentStrong corrosion resistanceMetallic material coating processesSteel tubeCorrosion resistant

The invention provides a steel and iron surface phosphating agent and a preparation method thereof, relating to the technical field of metal surface treating agents. The steel and iron surface phosphating agent comprises the following components in percentage by weight: 3% of potassium dichromate, 3.5% of composite phosphate, 16% of 65% nitric acid, 18% of 85% phosphoric acid, 0.1% of a CyDTA complexing agent, 7% of sodium sulfite and the balance of water. The steel and iron surface phosphating agent can be used for simultaneously phosphating and passivating the surface of a steel pipe; the quantity of acid fog generated by the phosphating agent in the actual production process is relatively low, so that the production environment of a workshop is greatly improved; more importantly, the steel and iron surface phosphating agent can form a uniform and compact phosphating film on the surface of a steel and iron workpiece after being stored for two months, and the problem of effect lowering caused by overlong storage time can be avoided; and in addition, the phosphating agent can also form a compact passivating film on the surface of the steel pipe, and the steel pipe treated by using the phosphating agent has favorable corrosion resistance.

Owner:HUNAN JINHUA SCI & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com