Steel pickling and water recycling method

A technology of steel pickling and water circulation, applied in the direction of metal material coating process, etc., to reduce acid mist, improve production efficiency, and avoid ash hanging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

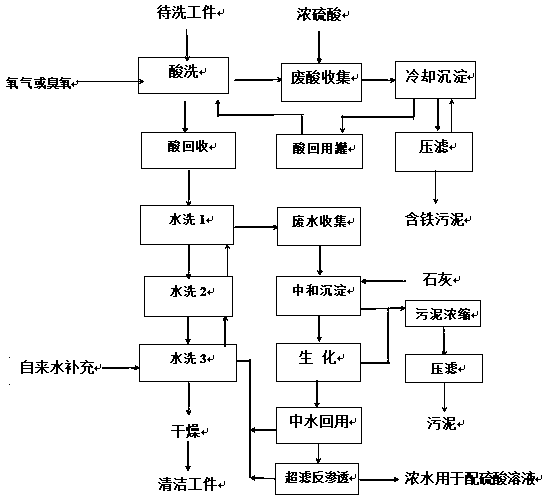

Method used

Image

Examples

Embodiment 1

[0055] Prepare a pickling solution with 35% sulfuric acid, 8% accelerator, and 0.5% corrosion inhibitor. Air is introduced into the pickling solution and the temperature of the pickling solution is controlled to 60°C. Pickling the 304 stainless steel material with a black surface, after 35 minutes of pickling, the surface of the stainless steel reveals a silvery white matrix. Pickling the 316L stainless steel material with black surface, after pickling for 50 minutes, the surface of the stainless steel reveals a silvery white matrix.

Embodiment 2

[0057] Prepare a pickling solution with 28% sulfuric acid, 5% accelerator, and 1% corrosion inhibitor. Air is introduced into the pickling solution and the temperature of the pickling solution is heated to 40°C. Carry out pickling to the carbon steel with black surface, 5 minutes steel surface reveals silver-white matrix.

Embodiment 3

[0059] An anchor chain factory uses a large number of carbon steel wires with a diameter of 6-12mm. Before processing the anchor chain, it is pickled and derusted, and the hydrochloric acid pickling process is used. Because the rinsing water contains hydrochloric acid, after neutralization with lime, a large amount of salty wastewater containing calcium chloride will be produced, making it difficult to achieve zero discharge.

[0060] Empty all the hydrochloric acid in the pickling pool. The size of the acid pool is 3 meters long, 2.5 wide, and 2.5 deep, with an effective volume of 12 cubic meters. Prepare a pickling solution in the acid pool with 25% sulfuric acid, 3% accelerator, and 0.5% corrosion inhibitor, heat and control the temperature of the pickling solution to 40°C, use an acid-resistant pump to mix ozone with the pickling solution through a Venturi mixer, The ozone feed rate is 30g / hour. Each batch of about 1 ton round steel wire rods is derusted in the pickling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com