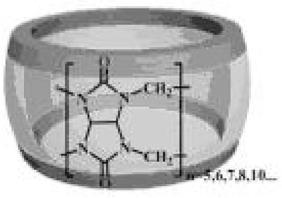

A kind of cucurbit compound type hydrochloric acid pickling corrosion inhibitor

A pickling corrosion inhibitor and composite technology, applied in the field of metal pickling corrosion inhibitor, can solve the problems of unstable corrosion inhibitor, low corrosion inhibition rate and high price, and achieve low acid mist and high corrosion inhibition efficiency. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

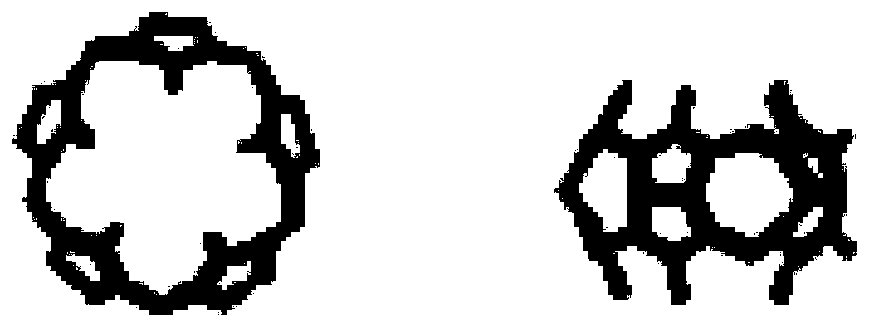

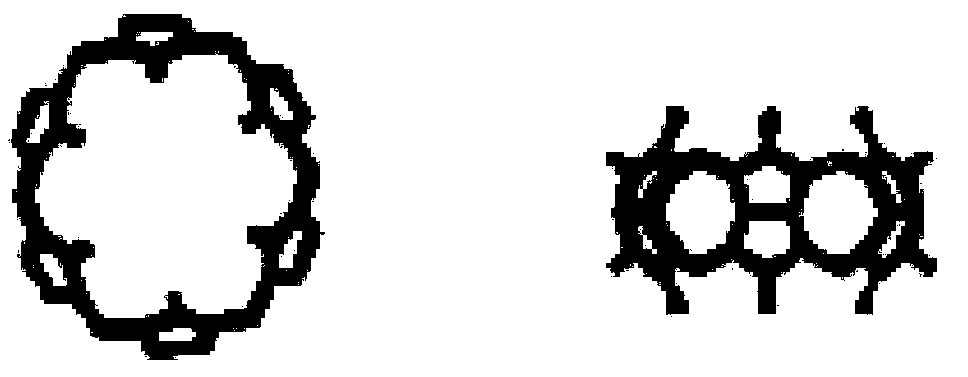

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the preparation method and operation steps of hydrochloric acid pickling corrosion inhibitor of the present invention are as follows: first add water to dilute to certain concentration with commercially available concentrated hydrochloric acid, get this hydrochloric acid solution and add a certain amount of melon ring, obtain corrosion inhibitor solution, Put the corrosion inhibitor solution into the constant temperature equipment, and control the temperature at 20°C±1°C to carry out corrosion inhibition pickling on the iron for 4h. The specimens were cleaned and dried to constant weight to calculate the corrosion inhibition rate. The result is as follows:

[0020]

Embodiment 2

[0021] Embodiment 2: the preparation method and operation steps of hydrochloric acid pickling corrosion inhibitor of the present invention are as follows:

[0022] First dilute to a certain concentration with commercially available concentrated hydrochloric acid and water.

[0023] The auxiliary corrosion inhibitor is obtained by mixing polyethylene glycol and triton at a weight ratio of 1:1.

[0024] Take the hydrochloric acid solution and add a certain amount of melon ring and corrosion inhibitor to obtain a corrosion inhibitor solution. Put the corrosion inhibitor solution into a constant temperature equipment, and control the temperature at 20°C ± 1°C to carry out corrosion inhibition pickling on iron for 4 hours. The specimens were cleaned and dried to constant weight to calculate the corrosion inhibition rate. The result is as follows:

[0025]

Embodiment 3

[0026] Embodiment 3: the preparation method and operation steps of hydrochloric acid pickling corrosion inhibitor of the present invention are as follows: first add water to dilute to certain concentration with commercially available concentrated hydrochloric acid, get this hydrochloric acid solution and add a certain amount of six yuan cucurbit ring and cinnamaldehyde, obtain Corrosion inhibitor solution, put the corrosion inhibitor solution into constant temperature equipment, and control the temperature at 20°C ± 1°C to carry out corrosion inhibition pickling on iron for 4 hours. The specimens were cleaned and dried to constant weight to calculate the corrosion inhibition rate. The result is as follows:

[0027]

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com