Cleaning agent for foil surface cleaning, preparation method of cleaning agent for foil surface cleaning and foil surface cleaning method

A surface cleaning and cleaning agent technology, which is applied in the field of cleaning agents, can solve problems such as foil erosion, strong acid solution volatilization, increased alcohol washing, water washing or drying, etc., to reduce pollution and emissions, clean the surface of the foil, and promote The effect of removing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

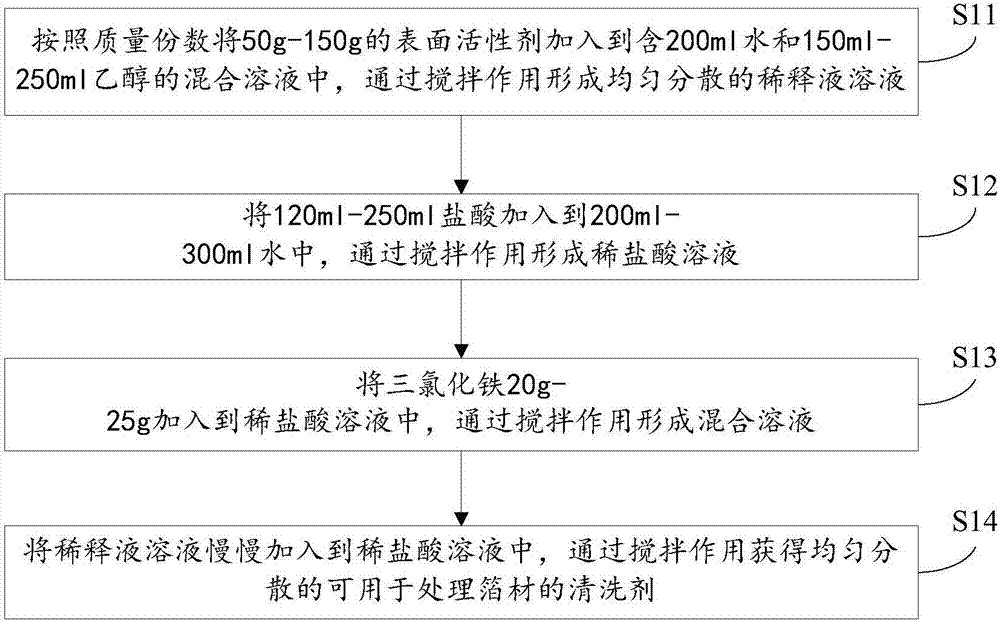

[0040] refer to figure 1 , the present invention also provides a preparation method of a cleaning agent for foil surface cleaning, the preparation method comprising the following steps:

[0041] Step S11, adding 50g-150g of surfactant into the mixed solution containing 200ml of water and 150ml-250ml of ethanol according to the parts by mass, and forming a uniformly dispersed diluent solution by stirring.

[0042] Step S12, adding 120ml-250ml hydrochloric acid into 200ml-300ml water, and forming a dilute hydrochloric acid solution by stirring.

[0043] Step S13, adding 20g-25g of ferric chloride into the dilute hydrochloric acid solution, and forming a mixed solution by stirring.

[0044] Step S14, slowly adding the diluent solution into the dilute hydrochloric acid solution, and obtaining a uniformly dispersed cleaning agent that can be used to treat the foil through stirring.

[0045] In the step of adding 50g-150g of surfactant to the mixed solution containing 200ml of water...

Embodiment 1

[0050] The proportion of each component of the cleaning agent is as follows:

[0051] Hydrochloric acid solution: 250ML;

[0052] Ferric chloride: 25 grams;

[0053] Sodium dodecylbenzenesulfonate: 40 grams;

[0054] Coconut oil fatty acid diethanolamide: 60 grams;

[0055] Ethanol: 150ML;

[0056] Purified water: 400ML.

[0057] Wherein, the preparation method of the cleaning agent is as follows: first, 40 grams of sodium dodecylbenzenesulfonate is added to a mixed solution of 150ML ethanol and 200ML water, and stirred at a stirring speed of 400 rpm until completely dissolved, and then coconut oil fatty acid two Add 60 grams of ethanolamide into the mixed solution and stir at a stirring speed of 200 rpm until completely dissolved to form a uniformly dispersed solution A. Then add 250ML of hydrochloric acid solution into 200ML of water, and form a uniformly dispersed dilute hydrochloric acid solution by physical stirring. Then 25 grams of ferric chloride was added into t...

Embodiment 2

[0060] The proportion of each component of the cleaning agent is as follows:

[0061] Hydrochloric acid solution: 250ML;

[0062] Ferric chloride: 25 grams;

[0063] Sodium lauryl sulfate: 30 grams;

[0064] Alkyl glycosides: 40 grams;

[0065] Sodium oleate: 10 grams;

[0066] Ethanol: 200ML;

[0067] Purified water: 500ML.

[0068] Wherein, the preparation method of the cleaning agent is as follows: first, 30 grams of sodium lauryl sulfate is added to a mixed solution of 200ML ethanol and 200ML water and stirred at a stirring speed of 400 rpm until completely dissolved, then 10 grams of sodium oleate is added and mixed in Stir at a stirring speed of 400 rpm until completely dissolved, and finally add 40 grams of alkyl glycoside and stir at a stirring speed of 200 rpm until completely dissolved to form a uniformly dispersed solution A. Then add 250ML of hydrochloric acid solution into 300ML of water, and form a uniformly dispersed dilute hydrochloric acid solution by ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com