Technology for preparing sulfuric acid

A kind of process, sulfuric acid technology, applied in the direction of sustainable manufacturing/processing, sulfur compounds, chemical industry, etc., can solve the problems of imperfection, poor quality, low sulfur purity, etc., and achieve the effect of solving environmental protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

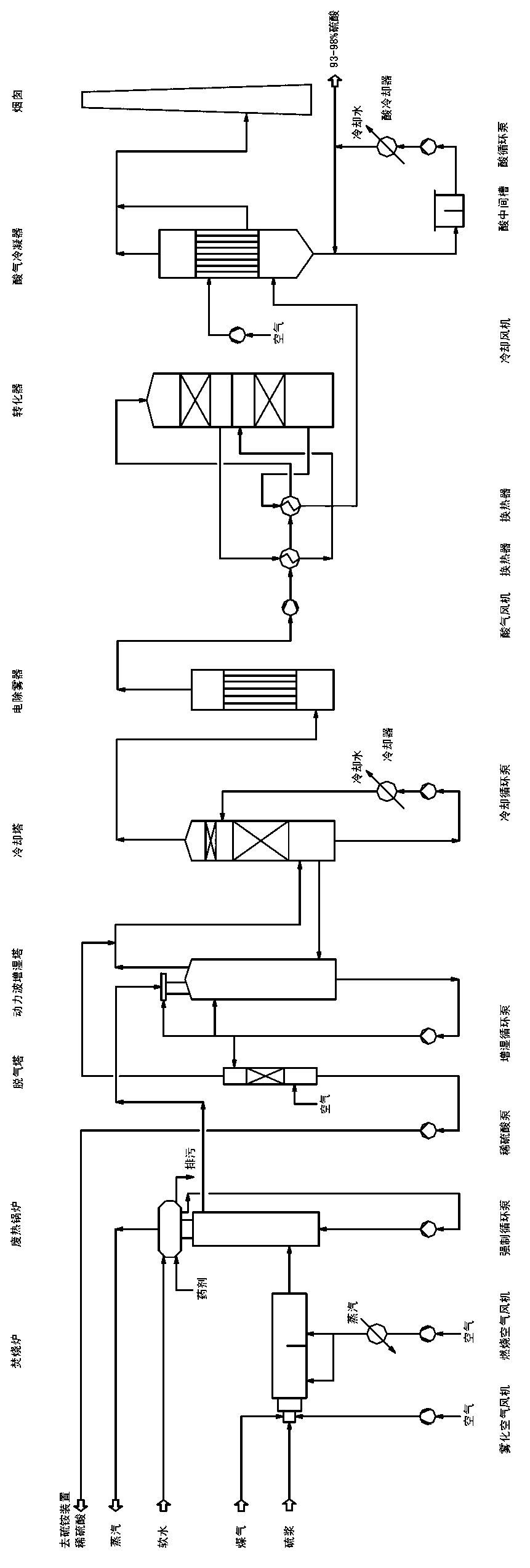

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] A process for producing sulfuric acid, which uses low-quality sulfur generated after wet oxidation desulfurization of coke oven gas and salt waste liquid containing sulfur as raw materials, through incineration, waste heat recovery, wet purification, wet contact conversion, condensation Acid-forming process to produce concentrated sulfuric acid.

[0019] 1. Sulfur and waste liquid incineration process

[0020] Use a pump to send the slurry formed by mixing the sulfur generated by the wet oxidative desulfurization of coke oven gas and the salt waste liquid containing sulfur to the nozzle of the incinerator, atomize it with compressed air, and send it into the incinerator, where the combustion air and Fuel gas and raw material slurry are incinerated in two stages at a temperature of about 1000-1200 ℃, one stage is for good combustion, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com