Steel acid pickling accelerant not containing metal elements and application method of steel acid pickling accelerant

A steel pickling and metal element technology, which is applied in the pickling treatment of silicon steel and the field of steel pickling accelerators, can solve the problems of difficult removal of metal elements, reduction of iron powder quality, large sedimentation sludge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

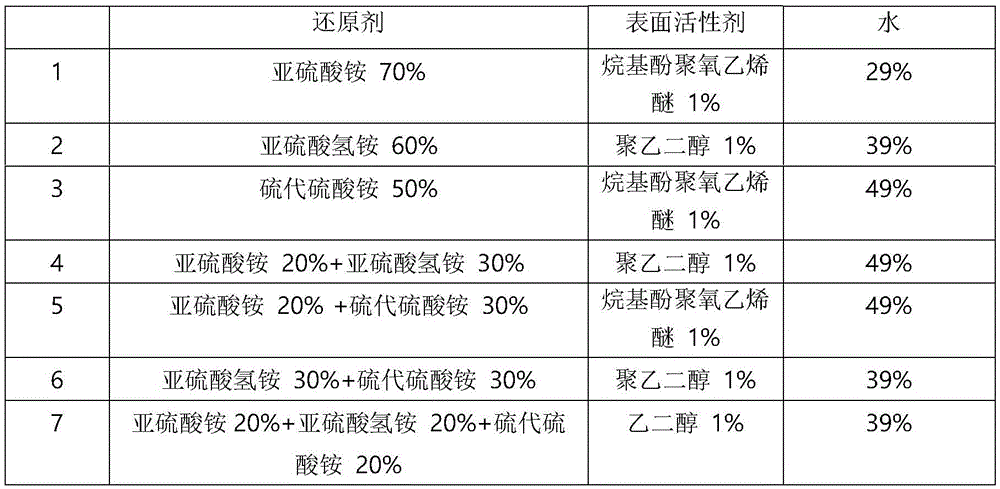

[0011] Example 1 Table 1 below provides 7 formulations of steel pickling accelerators, but the formulations that can actually be used are not limited to the following, as long as they meet the content of the invention and the claims are within the scope of protection.

[0012] Table 1 steel pickling accelerator formula (by weight)

[0013]

Embodiment 2

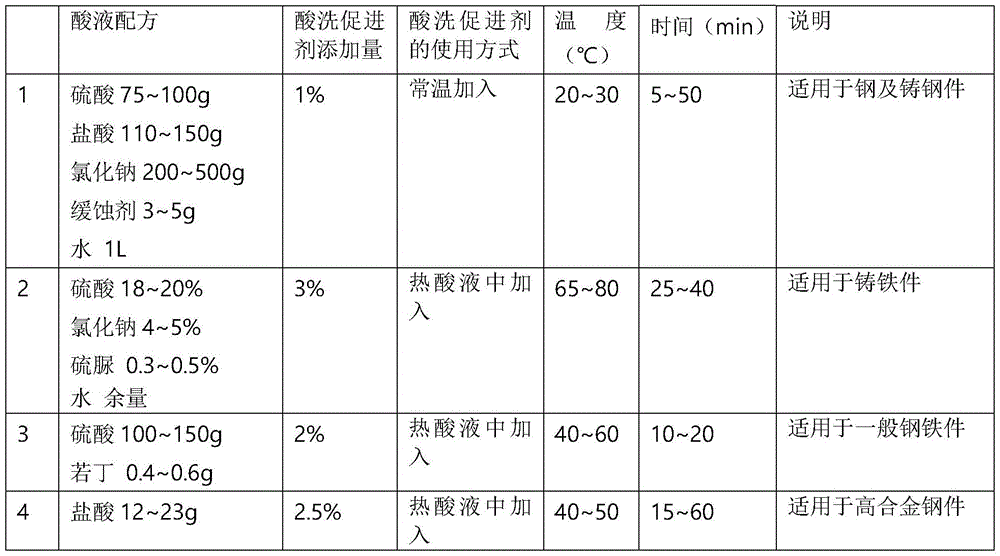

[0014] Example 2 The following table 2 provides the usage of the pickling accelerator in the acid solution, but the actual usable range is not limited to the following, as long as it meets the content of the invention and the claims, it is the scope of protection.

[0015] The addition mode of table 2 pickling accelerator in the pickling formula (by weight percentage)

[0016]

[0017]

Embodiment 3

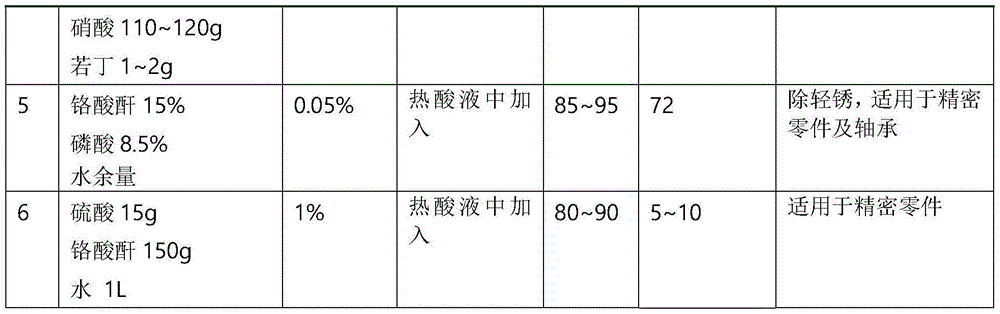

[0018] Example 3 Table 3 below shows the beneficial effect of adding the pickling accelerator described in Example 1.

[0019] The beneficial effect after table 3 adds pickling accelerator (all is 1% by adding amount)

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com