A nitric acid fog inhibitor and a preparing method thereof

A technology of fog suppressant and nitric acid, applied in the field of nitric acid fog suppressant and its preparation, can solve problems such as complex proportioning, and achieve the effects of small dosage, reduced component usage, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

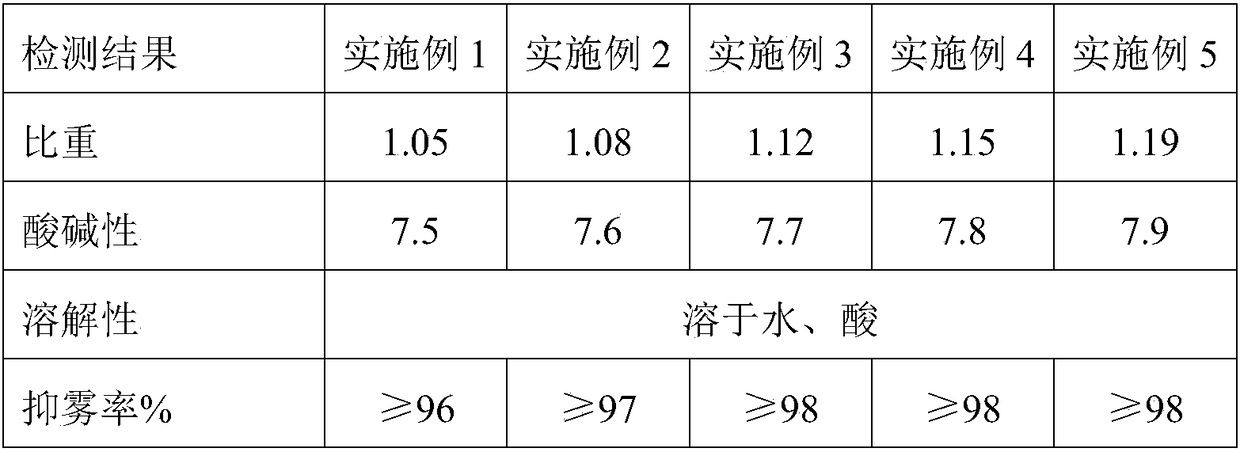

Examples

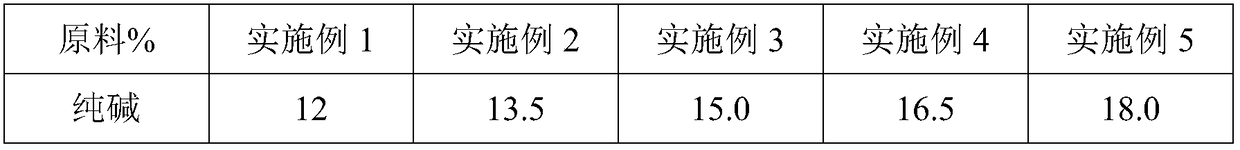

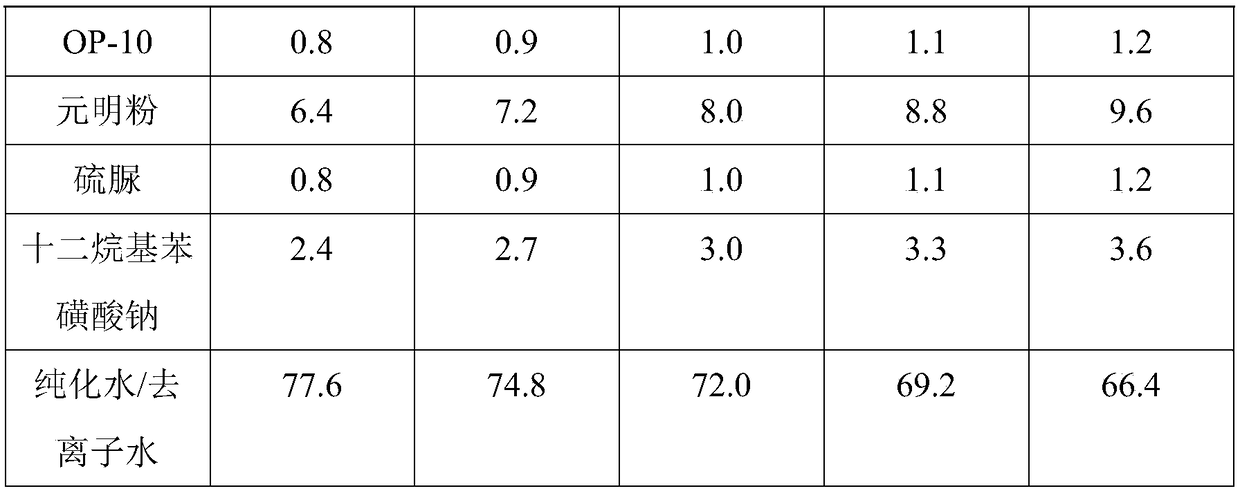

Embodiment 1

[0021] A nitric acid fog suppressant, comprising the following components in terms of mass percentage: 12.0% of soda ash, 0.8% of OP-10, 6.4% of sodium disulfide, 0.8% of thiourea, 2.4% of sodium dodecylbenzenesulfonate, and The amount is deionized water or purified water. The preparation method comprises the following steps: sequentially adding soda ash, OP-10, sodium disulfide, thiourea and sodium dodecylbenzenesulfonate into a reactor, then slowly adding water and stirring until all are dissolved to obtain the product.

Embodiment 2

[0023] A nitric acid fog suppressant, comprising the following components in terms of mass percentage: 13.5% of soda ash, 0.9% of OP-10, 7.2% of sodium disulfide, 0.9% of thiourea, 2.7% of sodium dodecylbenzenesulfonate, and The amount is deionized water or purified water. The preparation method comprises the following steps: sequentially adding soda ash, OP-10, sodium disulfide, thiourea and sodium dodecylbenzenesulfonate into a reactor, then slowly adding water and stirring until all are dissolved to obtain the product.

Embodiment 3

[0025] A nitric acid fog suppressant, comprising the following components in terms of mass percentage: 15.0% of soda ash, 1.0% of OP-10, 8.0% of sodium disulfide, 1.0% of thiourea, 3.0% of sodium dodecylbenzenesulfonate, and The amount is deionized water or purified water. The preparation method comprises the following steps: sequentially adding soda ash, OP-10, sodium disulfide, thiourea and sodium dodecylbenzenesulfonate into a reactor, then slowly adding water and stirring until all are dissolved to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com