Surface-coated composite anode of porous aluminum rod and lead alloy for zinc electrodeposition and preparation method thereof

A technology of surface coating and composite anode, applied in electrodes, anodic oxidation, surface reaction electrolytic coating, etc., can solve the problems of reduction, interface resistance and short life, and achieve enlargement of contact area, good compactness, and easy oxidation prevention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

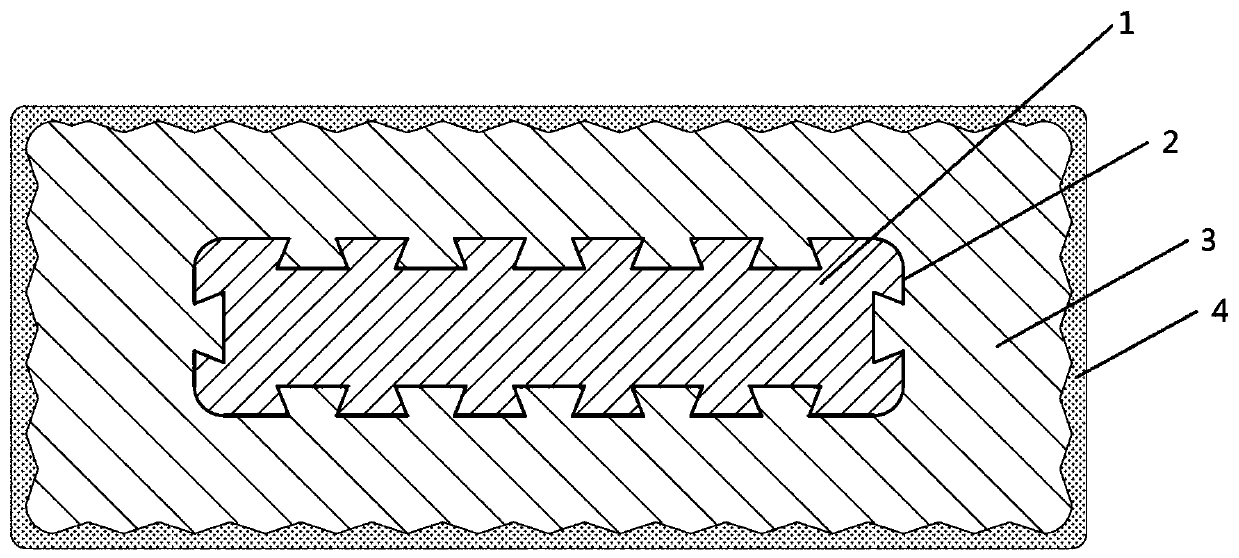

[0030] The preparation method of the composite anode coated with porous aluminum rod and lead alloy surface for zinc electrowinning, the steps are as follows:

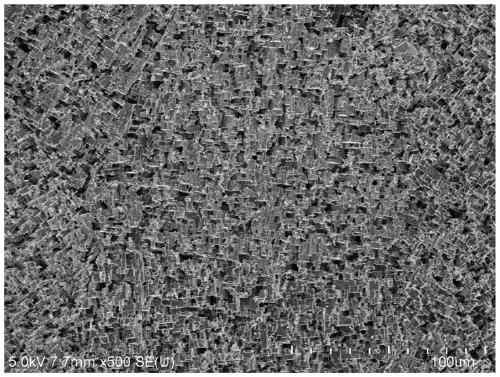

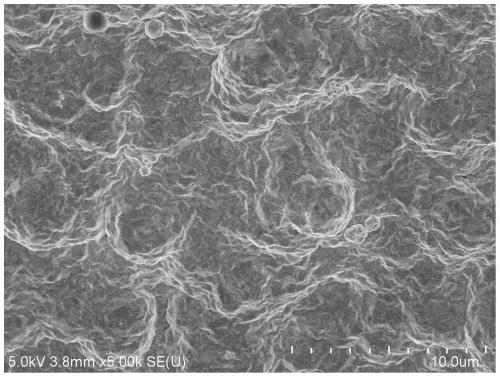

[0031] a. Preparation of matrix aluminum rod: firstly, the 5052 aluminum rod is drawn by extrusion, and then degreased, degreased in NaOH solution with a mass fraction of 15% for 8 minutes, then washed with water immediately, and then placed on the phosphoric acid anode In the oxidizing solution, pure lead is used as the cathode, the temperature is 20°C, and the anode current density is 2A / dm 2 , the voltage is 30V, after electroplating under air blowing for 30min, a large amount of water is washed, and then placed in HC1 with a mass fraction of 20% for activation for 20min, the activation temperature is controlled at 30°C, and then washed with deionized water to obtain a surface such as figure 2 Porous matrix aluminum rod 1 is shown. The anodizing solution consists of phosphoric acid (H 3 PO 4 ) 200g / L, oxalic aci...

Embodiment 2

[0039] The preparation method of the composite anode coated with porous aluminum rod and lead alloy surface for zinc electrowinning, the steps are as follows:

[0040] a. Preparation of matrix aluminum rod: firstly, the 1060 aluminum rod is drawn by extrusion, and then degreased, degreased in NaOH solution with a mass fraction of 20% for 1 min, then washed with water immediately, and then placed on a phosphoric acid anode In the oxidizing solution, pure lead is used as the cathode, the temperature is 30°C, and the anode current density is 1A / dm 2 , the voltage is 50V, after electroplating under air blowing for 50min, washed with a large amount of water, placed in 5% HCl for activation for 30min, the activation temperature is controlled at 50°C, and then washed with deionized water to obtain a porous matrix aluminum rod 1. The composition of the anodizing solution is H 3 PO 4 300g / L, H 2 C 2 o 4 2H 2 O 10g / L, NaC 12 h 25 SO 4 0.5g / L;

[0041] b. Preparation of Pb / Ag m...

Embodiment 3

[0048] The preparation method of the composite anode coated with porous aluminum rod and lead alloy surface for zinc electrowinning, the steps are as follows:

[0049] a. Preparation of the matrix aluminum rod: firstly, the 6061 aluminum rod is drawn by extrusion, and then it is degreased, degreased in a NaOH solution with a mass fraction of 10% for 10 minutes, and then washed with water immediately, and then placed on the phosphoric acid anode In the oxidizing solution, pure lead is used as the cathode, the temperature is 10°C, and the anode current density is 3A / dm 2 , the voltage is 20V, after electroplating under air blowing for 10min, wash with a large amount of water, place in HCl with a mass fraction of 30% to activate for 2min, control the activation temperature at 20°C, and then wash with deionized water to obtain a porous matrix aluminum rod 1. The composition of the anodizing solution is H 3 PO 4 150g / L, H 2 C 2 o 4 2H 2 O 3g / L, NaC 12 h 25 SO 4 0.05g / L;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com