Wet detoxification and bioremediation combined method for chromium slag and chromium-contaminated soil

A wet detoxification technology for chromium-contaminated soil is applied in the field of wet detoxification combined with bioremediation of chromium slag and chromium-contaminated soil. The effect of small area, optimized working environment and high engineering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

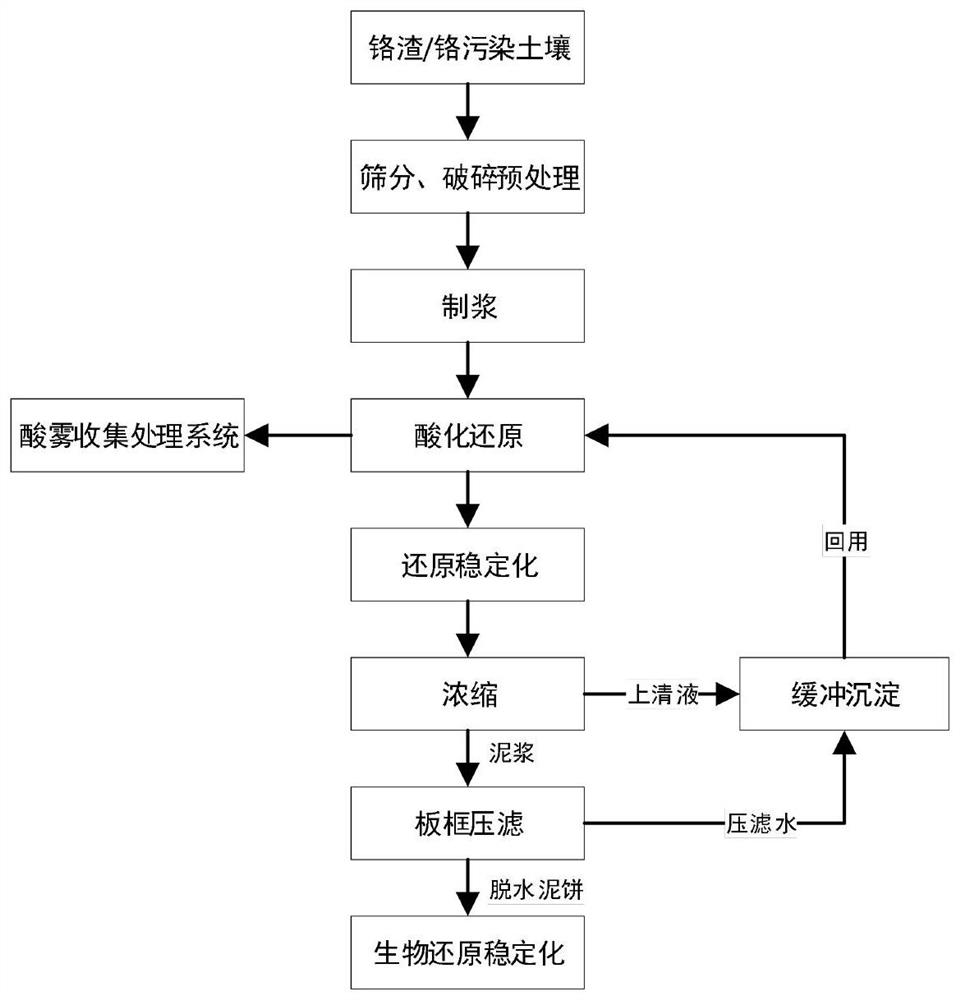

Method used

Image

Examples

Embodiment 1

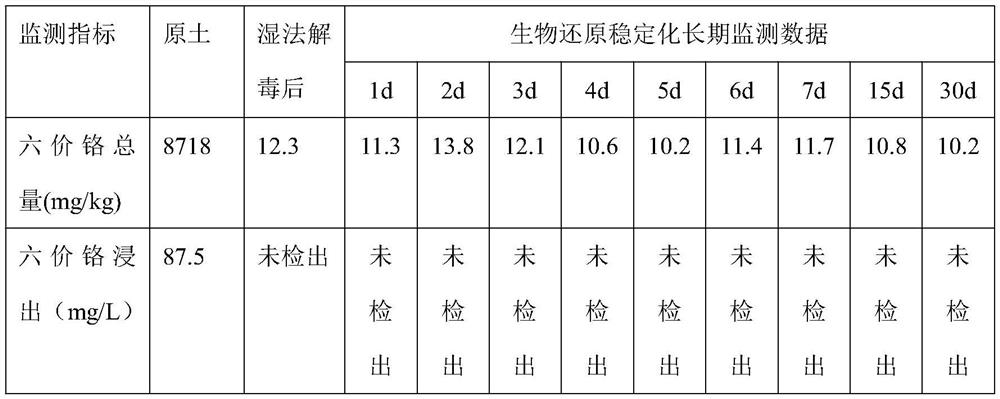

[0060] In the chromium slag at the original site of a chromium salt factory in Changsha, Hunan, the total amount of hexavalent chromium was 8718mg / kg, and the leaching concentration of hexavalent chromium was 87.5mg / L.

[0061] Step 1: After the chromium slag is screened and crushed for pretreatment, the large particles are removed and then transported to the mud mixing tank to make chromium-containing slurry. The solid-to-liquid ratio of the slurry is controlled to be 1:2.

[0062] Step 2: Transport the chromium-containing slurry to the acidification reduction tank, and add concentrated sulfuric acid, acetic acid, sodium tartrate, and ferrous sulfate to react. The pH in the acidification reduction tank was kept at 5-6, the acidification reduction reaction time was 5 hours, and the solid-liquid ratio was controlled at 1:3. The mass percentage of concentrated sulfuric acid, acetic acid, sodium tartrate, and ferrous sulfate solution is 80%; wherein the mass percentage of concent...

Embodiment 2

[0070] The chromium slag and soil mixture at the original site of a chromium salt factory in Changsha, Hunan, the total amount of hexavalent chromium is 4787mg / kg, and the leaching concentration of hexavalent chromium is 66mg / L.

[0071] Step 1: After sieving and crushing the mixture of chromium slag and soil for pretreatment, remove large particles and transport it to the mud mixing tank to make chromium-containing slurry. The solid-to-liquid ratio of the slurry is controlled to be 1:2.

[0072] Step 2: Transport the chromium-containing slurry to the acidification reduction tank, and add concentrated sulfuric acid, citric acid, sodium citrate, and ferrous sulfate to react. The pH in the acidification reduction tank was kept at 5-6, the acidification reduction reaction time was 4 hours, and the solid-liquid ratio was controlled at 1:3. The mass percentage of concentrated sulfuric acid, citric acid, sodium citrate, and ferrous sulfate solution is 60%; wherein the mass percentag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com