Method for producing ink-jet printing substrate in curtain type coating manner

An inkjet printing and curtain application technology, applied in the field of printing substrates, can solve the problems of inaccurate and stable production control, poor color reproducibility, product quality fluctuation, etc., to achieve stable coating performance and coating process, and uniform ink absorption. The effect of consistent, uniform coating distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

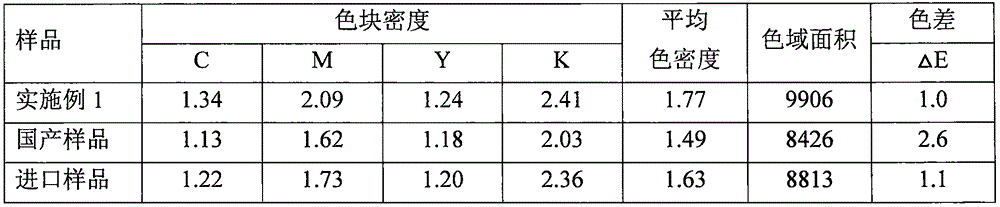

Examples

Embodiment approach 1

[0021] Art rice paper for color inkjet printing adopts 60g / m 2 The machine-made Xuan paper is base paper, the front coating adopts the curtain coating method, and the back coating adopts the gravure roller coating method. Both the surface and the back coating are coated once, and the coating production is completed at one time. Surfactants are added to the surface coating, the dynamic surface tension is 30mN / m, and the addition amount is 1.5‰ of the wet content of the coating; the dosage of thixotropic pigment calcium silicate is 20%, and the solid content of the coating is 25%; the unit flow rate of the coating curtain 0.8cm 2 / s; the coating speed is 250m / min, the die head of the curtain coating is the falling curtain type, and the gap width of the die head is 0.3mm; the coating temperature is controlled at 20-25°C during coating, and the coating amount is 10-12g / m 2 ;The back coating adopts surface sizing starch, the concentration is 10%, and the coating amount is 1~2g / m...

Embodiment approach 2

[0025] Dye sublimation transfer paper adopts 80g / m 2 The machine-made paper is base paper, the front primer layer is coated with a bar, the front layer is coated with a curtain coating, and the back layer is coated with a gravure roll. Complete coating production at one time. Surfactant is added to the top coating, the dynamic surface tension is 35mN / m, and the addition amount is 1.0‰ of the wet content of the coating; the amount of thickener is 0.2%; the amount of thixotropic pigment calcium silicate is 8%, and the solid content of the coating is 18 %; The unit flow rate of the paint curtain is 0.6cm 2 / s; the coating speed is 150m / min, the die head of the curtain coating is the falling curtain type, and the gap width of the die head is 0.4mm; the coating temperature is controlled at 20-25°C during coating, and the coating amount is 6-8g / m 2 ; The back coating adopts surface sizing starch, the concentration is 8%, and the coating amount is 1-1.5g / m 2 ; Moisture after coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thixotropic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com