Loquat enzyme nutrient solution and preparation method thereof

A technology of loquat enzyme and nutrient solution, which is applied in the direction of medical formula, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of high price of Chuanbei, heavy economic burden, unbearable for ordinary people, etc., and achieve high active ingredients , good quality, the effect of improving human immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

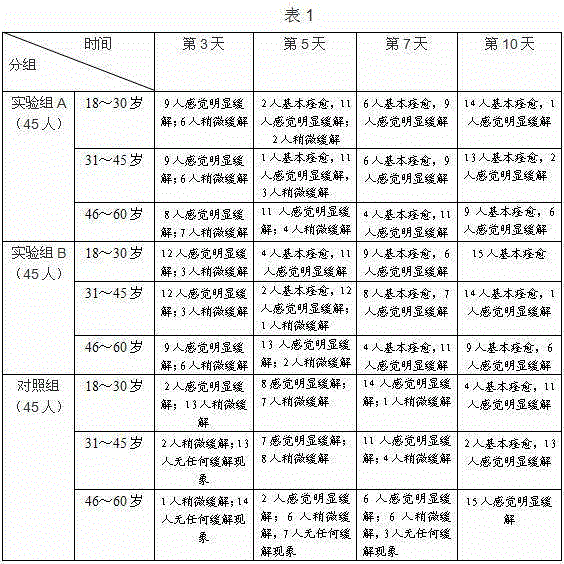

Image

Examples

Embodiment 1

[0024] The raw materials used in this loquat enzyme nutrient solution are:

[0025] Loquat 15kg, dried loquat leaves 2kg, honey 1kg, oligosaccharide 1kg, dry yeast 0.1kg, purified water 120kg.

[0026] The production method is:

[0027] A. Peel the loquat, remove the core, slice it, and beat it into loquat pulp for later use;

[0028] B. Boil the dried loquat leaves with the above-mentioned water until 90kg of water remains to obtain the loquat leaf solution, which is cooled to 20-35°C for subsequent use;

[0029] C, the loquat pulp, loquat leaf solution are mixed with honey, oligosaccharides, and dry yeast and mixed thoroughly, packed into a container, sealed and fermented for 15 days to obtain a fermented liquid;

[0030] D. Process and refine the fermented liquid obtained in step C with supercritical fluid extraction and separation technology, and pack it in 50 ml per pack.

Embodiment 2

[0032] The raw materials used in this loquat enzyme nutrient solution are:

[0033] Loquat 17kg, dried loquat leaves 2.5kg, honey 1.5kg, oligosaccharide 1.5kg, dry yeast 0.2kg, purified water 150kg.

[0034] The production method is:

[0035] A. Peel the loquat, remove the core, slice it, and beat it into loquat pulp for later use;

[0036] B. Boil the dried loquat leaves with the above-mentioned water until 100kg of water remains to obtain the loquat leaf solution, which is cooled to 20-35°C for subsequent use;

[0037] C, the loquat pulp, loquat leaf solution are mixed with honey, oligosaccharides, and dry yeast and mixed thoroughly, packed into a container, sealed and fermented for 25 days to obtain a fermented liquid;

[0038] D. Process and refine the fermented liquid obtained in step C with supercritical fluid extraction and separation technology, and pack it in 50 ml per pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com