Loading device for PCB hot pressing

A PCB board and loading device technology, which is applied in the field of PCB hot-pressing loading device, can solve the problems of PCB scrapping, economic loss, heavy work, etc., achieve the effect of reducing intermediate processes, quick operation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

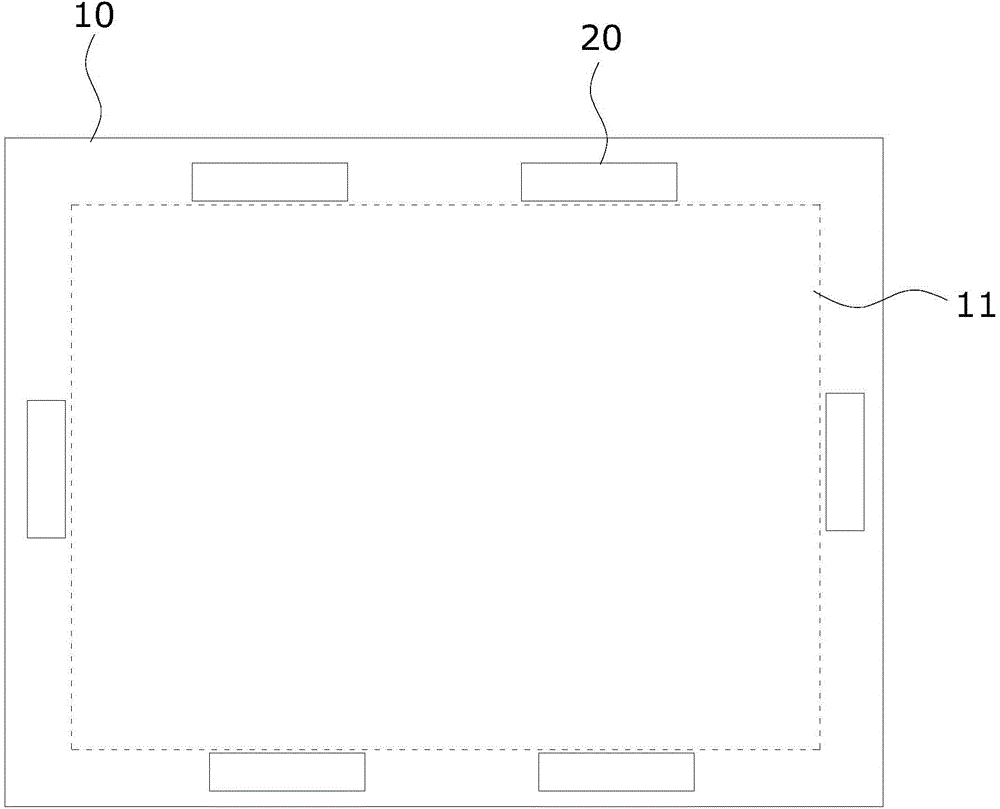

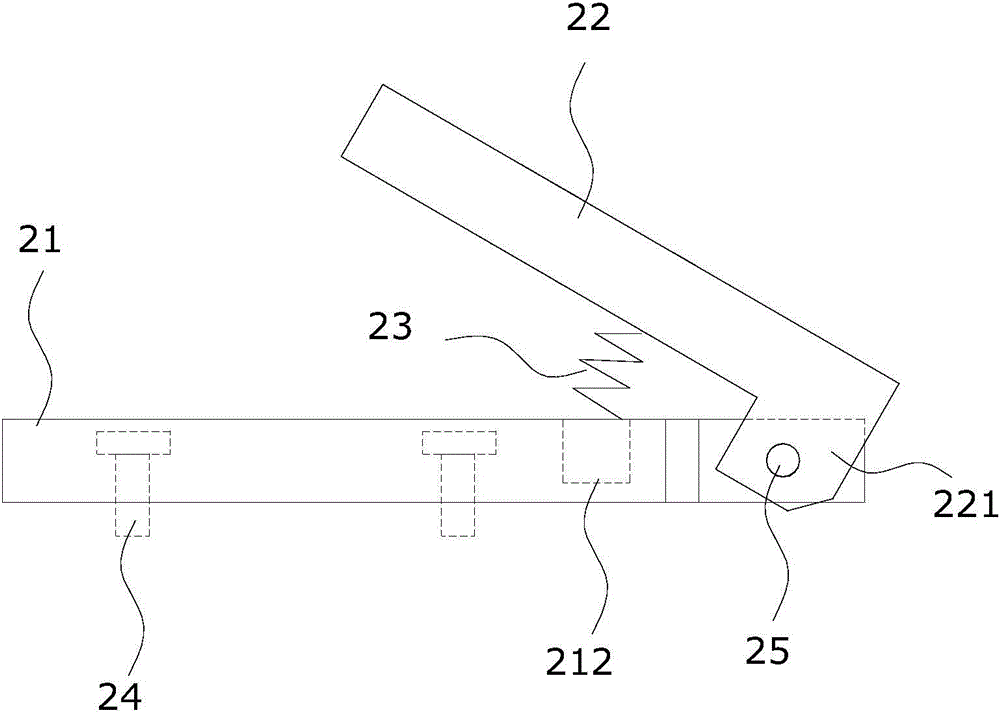

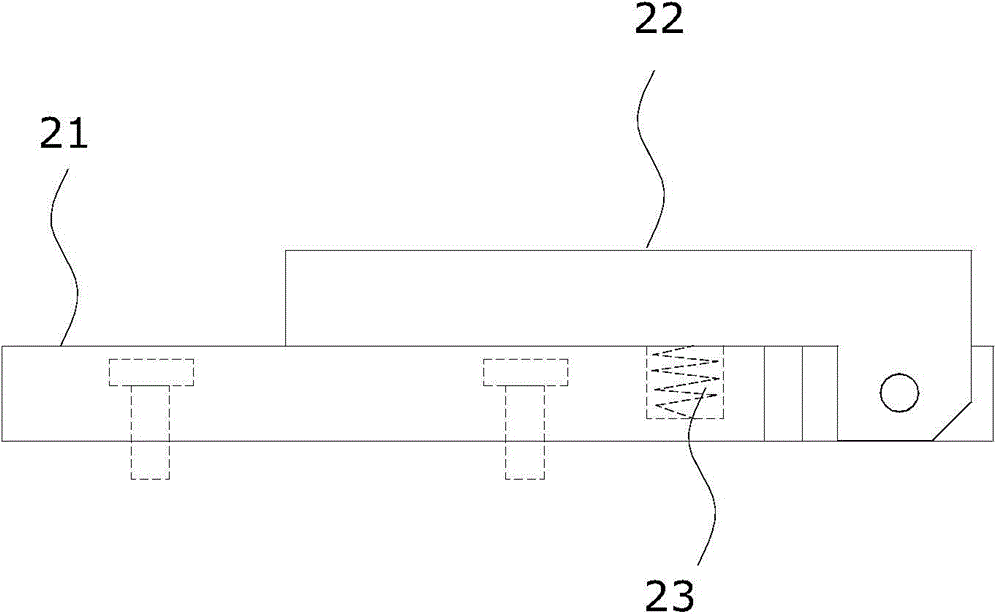

[0024] Such as Figure 1 to Figure 4 As shown, it is a loading device for hot pressing of PCB boards, including a steel plate chassis 10 for displaying PCB boards and a plurality of chrome-plated elastic retaining clips 20, and the elastic retaining clips 20 are arranged on the surface of the chassis 10 and can form a PCB In the display area of the panel, the elastic retaining clip 20 includes an elastic portion 22 and a fixed portion 21 connected to the chassis 10, one end of the fixed portion 21 is connected to one end of the elastic portion 22 in rotation, and there is also a set between the fixed portion 21 and the elastic portion 22 Elastic recovery member 23.

[0025] In this embodiment, one end of the fixing part 21 is provided with a convex connector 211, and one end of the elastic part 22 is provided with a grooved connector 221 matching the convex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com