Integrated type permanent magnet synchronous motor shell

A permanent magnet synchronous motor, an integrated technology, applied in the direction of synchronous machine parts, casing/cover/support, electrical components, etc., can solve the problems of complex production process, high production cost, poor heat dissipation effect, etc., and achieve failure The effect of low efficiency, low production cost and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

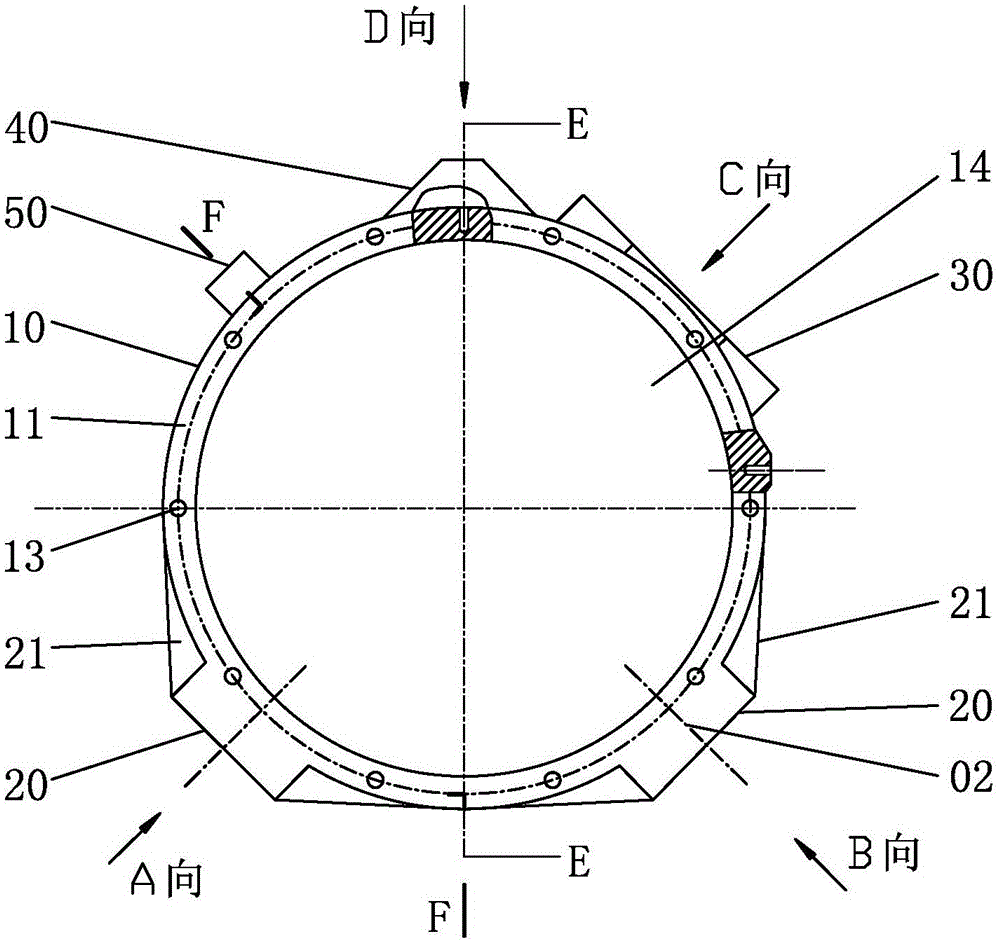

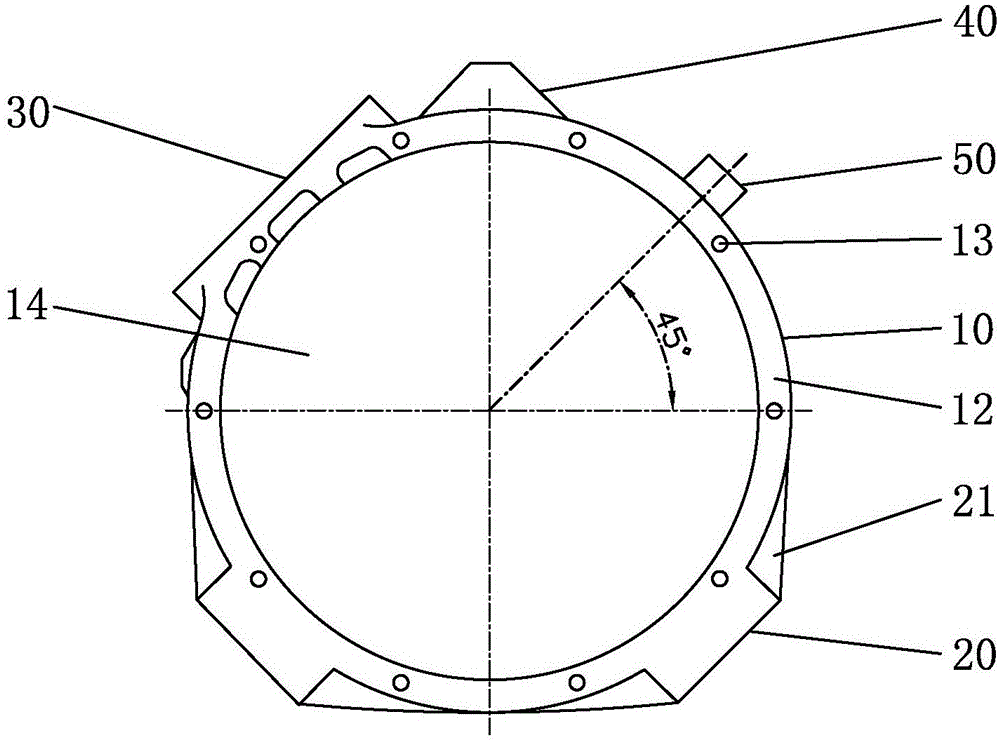

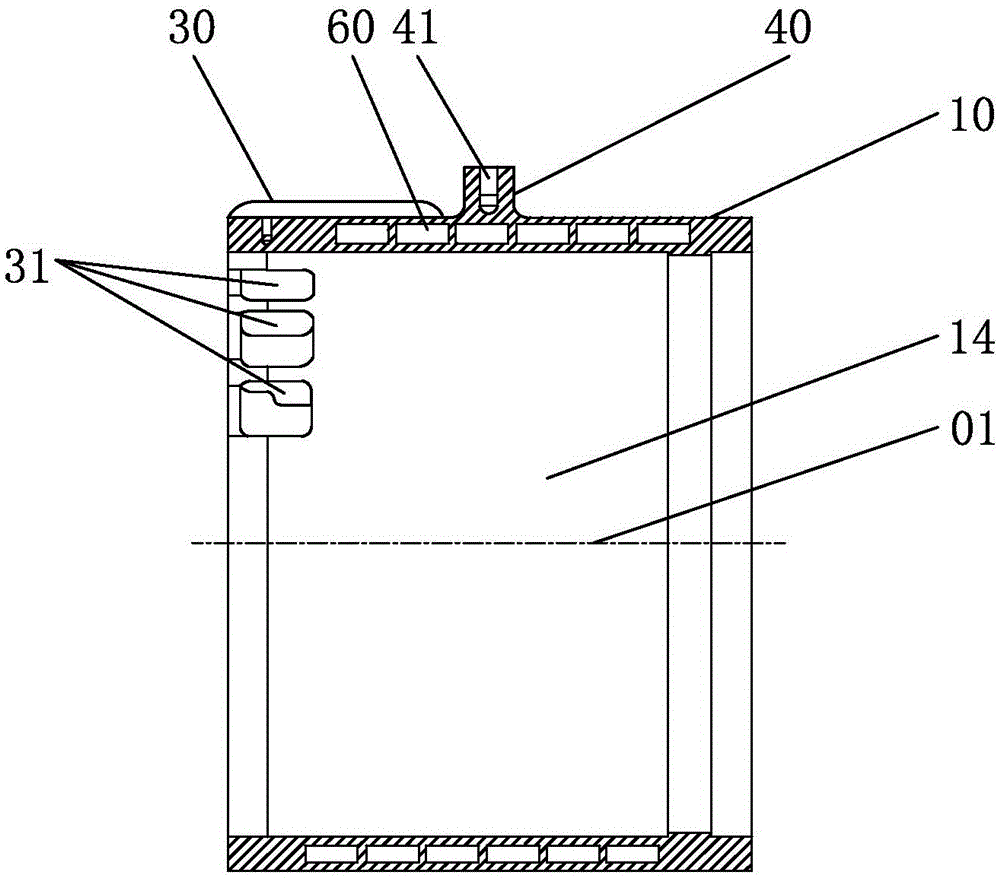

[0026] The present invention will be further described below with specific embodiments in conjunction with the drawings, see figure 1 — Picture 9 :

[0027] One-piece permanent magnet synchronous motor housing. The side wall 10 of the cylinder with a cylindrical center hole 14 has a spiral heat dissipation channel 60 integrally formed with the cylinder, and a junction box is integrally formed with the cylinder on the outer wall of the cylinder. 30. Lifting ears 40 and at least three circumferentially spaced convex strips 50 with the axis in the up and down direction. The inlet and outlet ports 62 at the upper and lower ends of the spiral heat dissipation channel 60 pass through the side wall 10 of the cylinder and are located on the left side of the junction box 30. The upper and lower parts of the strip 50 and the upper and lower sides of the other two protruding strips 50 are provided with mounting seats 20. Each mounting seat 20 is provided with two or more threaded blind hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com