Back auxiliary heating device for titanium and titanium alloy friction stir welding

A friction stir welding and auxiliary heating technology, used in metal processing equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of wear on the top of the stirring head, insufficient heat generation, etc., to reduce strength, avoid uneven heating temperature, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

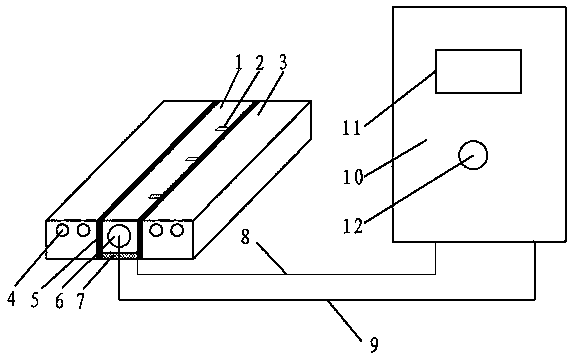

[0025] combine figure 1 Description of this embodiment is mainly aimed at titanium alloys with a thickness greater than 2 mm. In this application, the processing of titanium alloys with a thickness of 4 mm is taken as an example. A back auxiliary heating device for friction stir welding of titanium and titanium alloys in this embodiment includes a heating assembly , cooling components, insulation layer and control system four parts.

[0026]A back auxiliary heating device for friction stir welding of titanium and titanium alloys, including a support plate for supporting the welded parts and installed on the workbench and a control system for controlling the entire heating device, the support plate is composed of a welding The back backing plate 1 and two back backing plates 3 for fixing are spliced together, the back backing plate 1 for welding is sandwiched between the two back backing plates 3 for fixing, the back backing plate 1 for welding is located directly below the w...

Embodiment 2

[0032] combine figure 1 Describe this embodiment, a back auxiliary heating device for friction stir welding of titanium and titanium alloys in this embodiment includes four parts: heating assembly, cooling assembly, heat insulation layer and control system, the cooling assembly only uses the backing plate for fixing, no longer Adding cooling channels instead of feeding coolant is mainly because the thickness of the titanium alloy plate is small and the heating temperature is relatively low. The reaction between the plate and the components in the air can be ignored, so the cooling part can be used for cooling. Such a setting can save energy and reduce the cost of use. Other compositions and connections are the same as in Embodiment 1.

Embodiment 3

[0034] combine figure 1 Describe this embodiment mode. A back auxiliary heating device for friction stir welding of titanium and titanium alloys in this embodiment mode includes four parts: a heating component, a cooling component, a heat insulating layer and a control system. The outside is wrapped with an insulating sleeve. Such setting can improve the heating efficiency and ensure the heating effect. Other composition and connection relation are identical with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com