Method for extracting lithium from lepidolite

A technology for lepidolite and lithium precipitation mother liquor, applied in the field of lithium extraction, can solve the problems of harmful leaching, increased cyclic load of pressure leaching kettle, complicated process, etc., and achieves the effects of reduced processing cost and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in more detail below by specific embodiment:

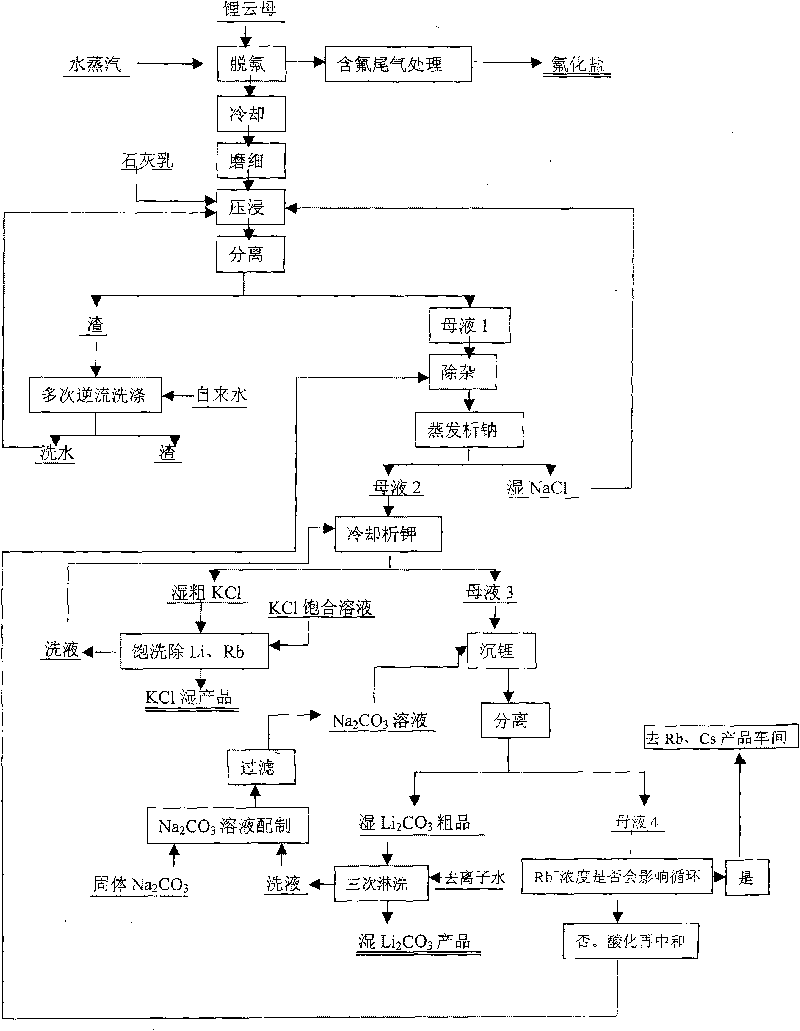

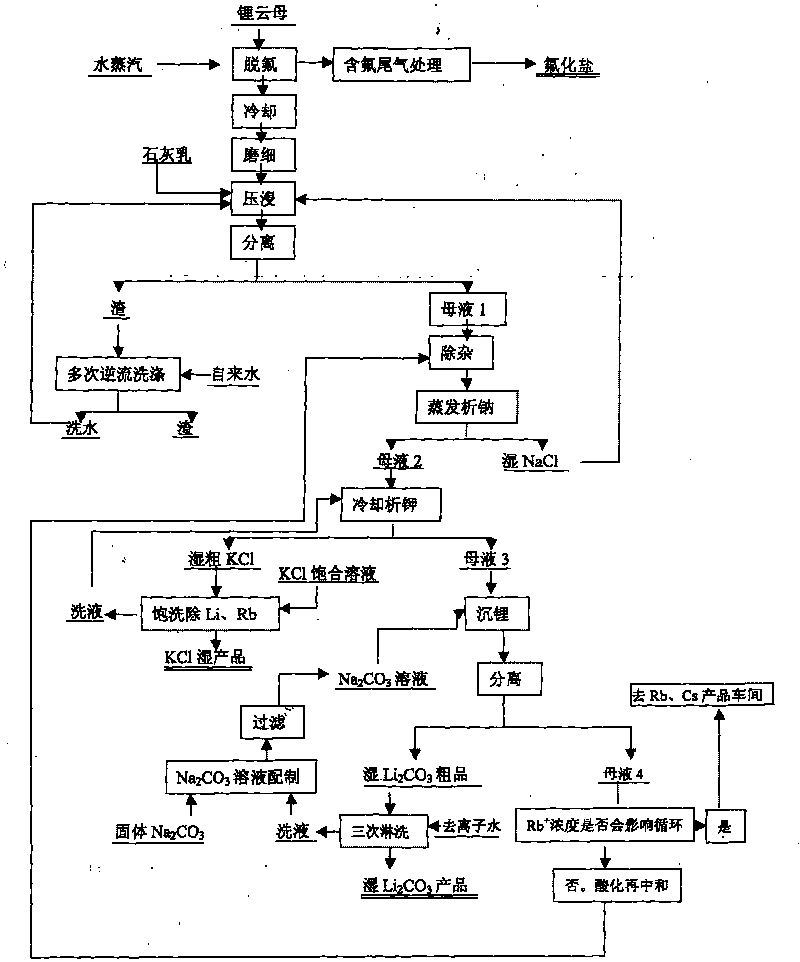

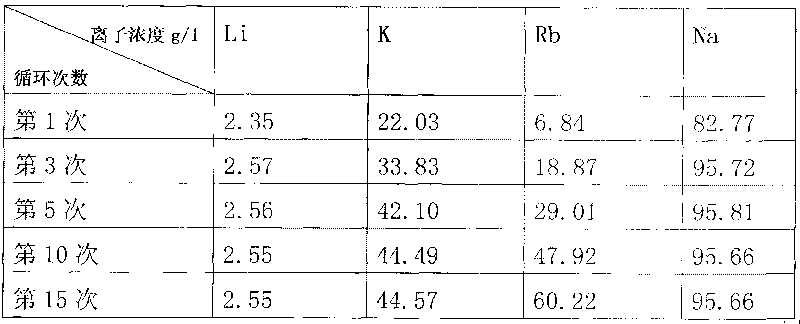

[0014] figure 1 It is a schematic diagram of the processing process in this example, which contains the following contents in turn:

[0015] ①Defluorination: put lepidolite ore into water at high temperature for steaming and roasting for defluorination, the main components in lepidolite after defluorination are shown in the following table: main components in defluorinated lepidolite (wt%)

[0016] F

Li 2 o

Na 2 o

K 2 o

Rb

Cs

mn

Al

Fe

1.02%

3.9%

2.92%

5.45%

0.725%

0.116%

0.26%

8.86%

0.41%

[0017] ②Grind lepidolite with a ball mill and pass through a 200-mesh sieve;

[0018] ③Press immersion: Take 200 mesh defluorinated lepidolite, add calcium oxide and sodium chloride according to a certain mass ratio and liquid-solid mass ratio, put it into a high-pressure reactor for pressure cookin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com