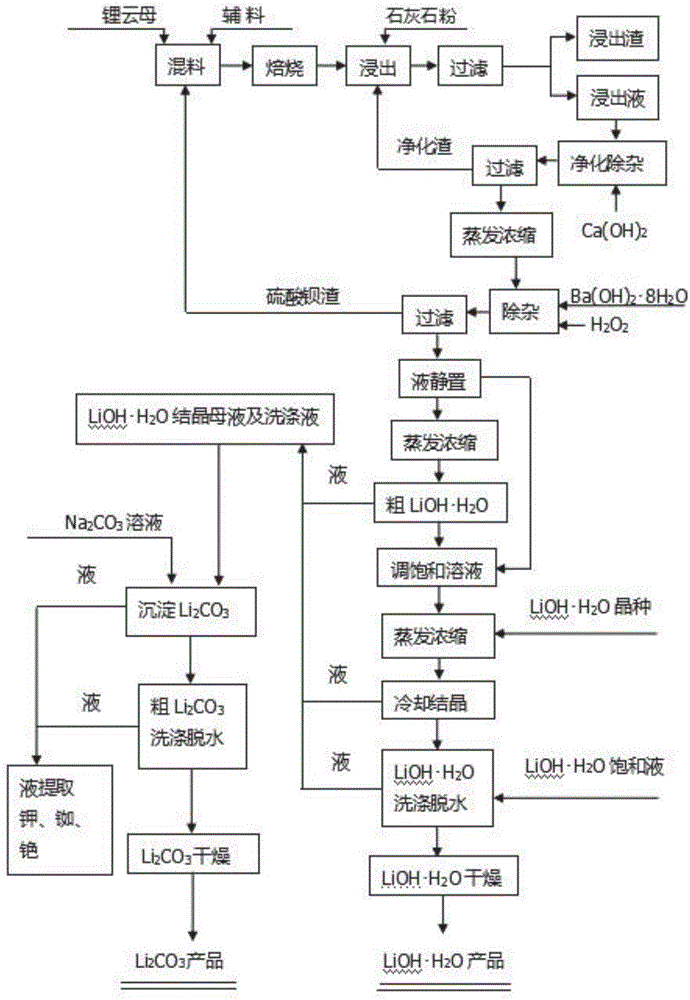

Method for extracting lithium from lepidolite concentrate

A lepidolite, lithium extraction technology, applied in the direction of lithium oxide;/hydroxide, lithium carbonate;/acid carbonate, etc., can solve the problem of material melting, low lithium grade, and easy formation of saturated double salt And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] Step (1): 2 kg of lepidolite concentrate (see Table 1 for composition): industrial grade CaSO 4 2H 2 O: Barite ore powder (containing BaSO 4 ≥90%) according to the weight ratio 1:0.3:0.15, add 3% water of the total material and mix evenly, put it into a stainless steel pan, and roast it in a muffle furnace at 920°C for 2h (turn it every 30 minutes), and observe that the roasted material There is a tendency to soften and melt, but it is not melted, and a roasted material is obtained.

[0104] Step (2): The roasted material that obtains is ground to -180 order and accounts for 80% powder in the vibrating ore mill, after water is adjusted into ore slurry in reaction tank by the solid-liquid ratio of 1: 2, press ore again: acid ( Weight ratio) = 1: 0.5, add concentrated sulfuric acid without heating and react for 2h, then add limestone powder (CaCO3≥90%) to adjust the pH value of the solution to 5, then perform suction filtration, and wash the filter residue twice with wa...

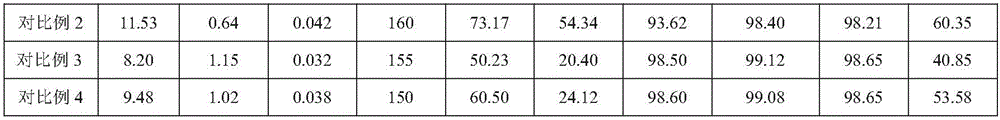

Embodiment 2

[0109] Compared with Example 1, the difference is that in step (1), lepidolite concentrate (see Table 1 for composition) 2kg: industrial grade CaSO 4 2H 2 O: the BaSO produced by the experiment of Example 1 4 Return slag (including BaSO 4 ≥90%) according to the weight ratio 1:0.2:0.2, add 3% water of the total material and mix evenly, put it into a stainless steel pan, and roast it in a muffle furnace at 950°C for 2 hours (turn it every 30 minutes), and observe that the roasted material There was no tendency or phenomenon of softening and melting, and a roasted material was obtained. Subsequent process is the same as in Example 1, and the results are shown in Table 2.

Embodiment 3

[0111] Mix 2000kg of lepidolite concentrate with industrial grade CaSO 4 2H 2 O: Barite ore powder (containing BaSO 4 ≥90%) by weight ratio 1:0.3:0.15, add 3% water of the total material and mix evenly, put it into the special short kiln for smelting provided by Laibin Smelter of Liuzhou Huaxi Group, the size of the short kiln is ¢2655mm×3462mm, Add the material to be roasted from the middle of the short kiln, and roast it with gas. When the temperature rises to 920°C, keep it warm for 2 hours. It is observed that the roasted material does not melt, and the material is ground with a Raymond machine until - After 180 mesh accounts for 80%, take a comprehensive sample of 2.5 kg to obtain the roasted material. Subsequent process is the same as in Example 1, and the results are shown in Table 2.

[0112] Note: the batching ratio of embodiment 3, roasting temperature, time and follow-up process are all with embodiment 1. The roasting equipment is a short kiln, and the short kil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com