Method for producing refined lithium sulfate solution used in lepidolite lithium-extracting technique by sulfuric acid process

A refined lithium sulfate and production method technology, which is applied in the field of lepidolite lithium extraction, can solve the problems of severe equipment corrosion, high cost, and low yield, and achieve the effects of easy separation of lithium and aluminum, lightening the burden, and high lithium yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

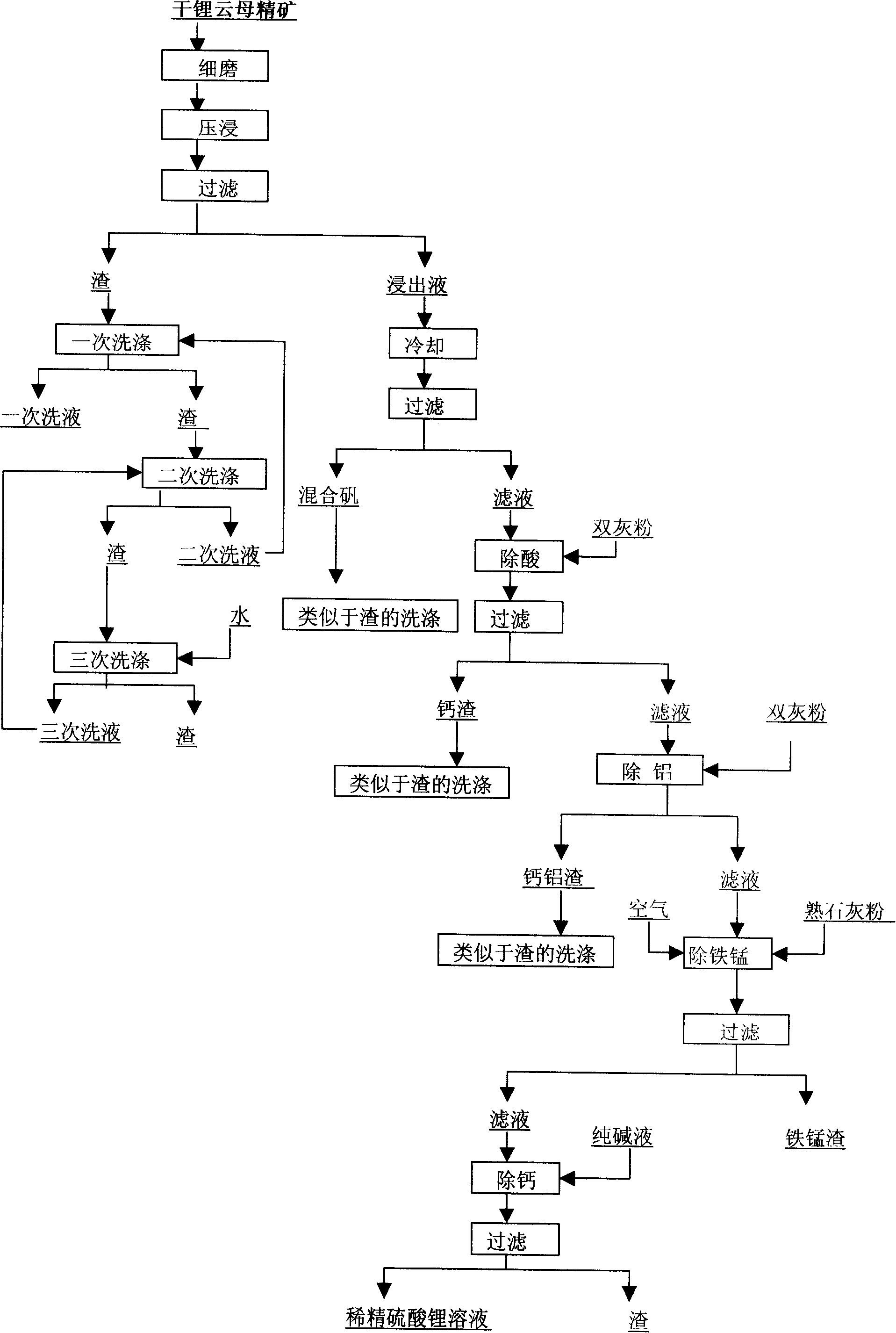

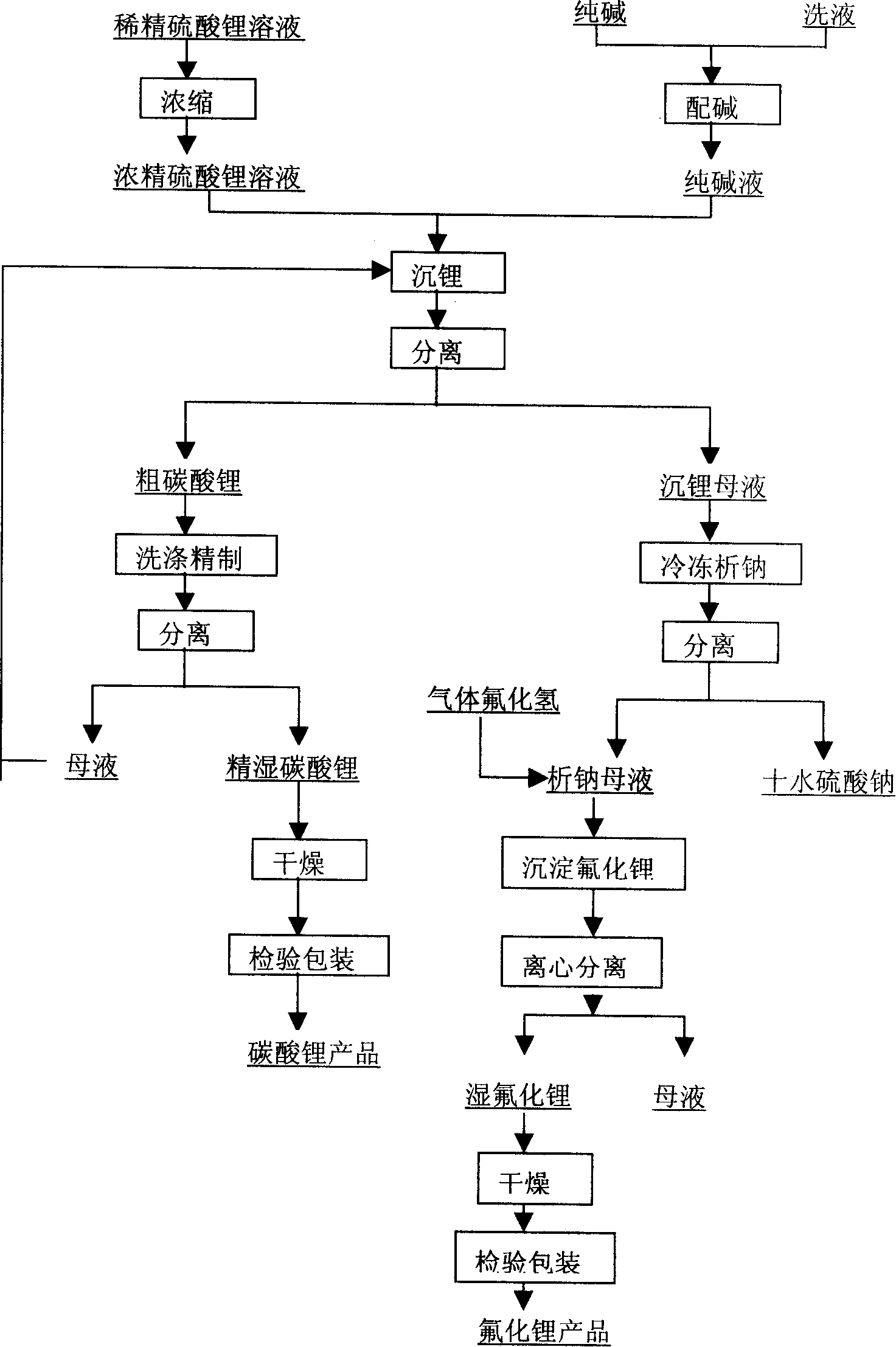

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment

[0020] This program includes the following steps in turn:

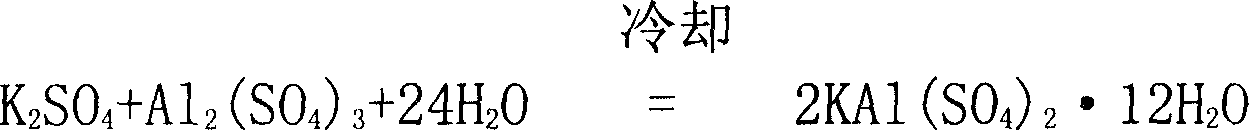

[0021] A. Leaching:

[0022] A-1. Raw materials: Lepidolite is a fluorine-containing aluminosilicate with a continuous layered tetrahedral structure, and its molecular formula is usually written as KLi 1.5 Al 1.5 [AlSi 3 o 10 ] (OH, F) 2 , the composition generally contains Li 2 O 1.2-5.9%, K 2 O 4.8-13.8%, Al 2 o 3 11.3-28.8%, SiO 2 46.9-60%, F 1.36-8.71%, H 2 O 0.65-3.15%, also contains Na 2 O, MgO, CaO, FeO, MnO and sometimes up to 3% Rb 2 O and up to 1.5% Cs 2 O.

[0023] The main composition of Yichun lepidolite used in this program is as follows:

[0024] Li 2 o

Na 2 o

K 2 o

Rb 2 o

Cs 2 o

Al 2 o 3

SiO 2

FeO

MnO

F

4.74

1.20

7.87

1.63

0.35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com