Beneficiation method of lithium ore

A beneficiation method and technology for lithium ore, which can be used in flotation, solid separation, etc., and can solve problems such as cumbersome beneficiation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

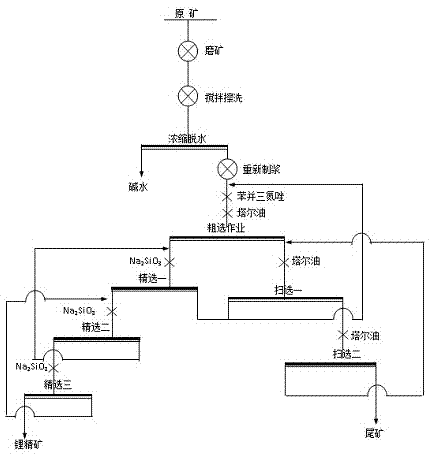

Image

Examples

Embodiment 1

[0022] The raw ore of a pegmatite lithium mine in China contains Li 2 O1.52%, the main lithium-containing minerals are spodumene, lepidolite and iron lepidolite, etc., and the main gangue minerals are quartz, plagioclase, microcline, etc.

[0023] The raw ore is crushed and ground to -0.074mm to account for 72%, and the pulp concentration is 40%, then NaOH is added to pH 12 and mechanically stirred and scrubbed for 45 minutes. The pulp after stirring and scrubbing is first concentrated and dehydrated to a pulp concentration of 60%, and then added with clean water to re-adjust the pulp to obtain a pulp concentration of 35% and a pH of 10.

[0024] The ore pulp enters the flotation operation after readjustment, and the flotation operation is one roughing, the second sweeping and the third beneficiation. For the roughing operation, first add 100g / t of benzotriazole, stir for 2 minutes, then add 150g / t of tall oil and stir for 5 minutes, then carry out the roughing operation, and...

Embodiment 2

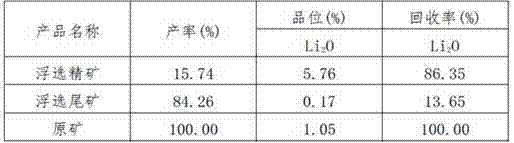

[0028] The raw ore of a pegmatite lithium ore contains Li 2 O1.05%, the main lithium-containing minerals are spodumene, lepidolite and iron lepidolite, etc., and the main gangue minerals are quartz, feldspar, etc.

[0029] The raw ore is crushed and ground to -0.074mm to account for 80%, and the pulp concentration is 40%, then NaOH is added to pH 12 and mechanically stirred and scrubbed for 45 minutes. The pulp after stirring and scrubbing is first concentrated and dehydrated to a pulp concentration of 58%, and then added with clean water to re-adjust the pulp to obtain a pulp concentration of 38% and a pH of 9. The ore pulp enters the flotation operation after readjustment, and the flotation operation is one roughing, the second sweeping and the third beneficiation. For the roughing operation, first add 80g / t of benzotriazole, stir for 2 minutes, then add 120g / t of tall oil and stir for 5 minutes, then carry out the roughing operation, and the flotation time is 3 minutes; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com