Environment-friendly release agent for fair-faced concrete and preparation method thereof

A technology of fair-faced concrete and mold release agent, which is applied in the manufacture of tools, ceramic molding machines, and the petroleum industry. It can solve the problems of high price, non-environmental protection, and poor apparent quality of concrete, and achieve low cost, eliminate air bubbles, and smear and spread. good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

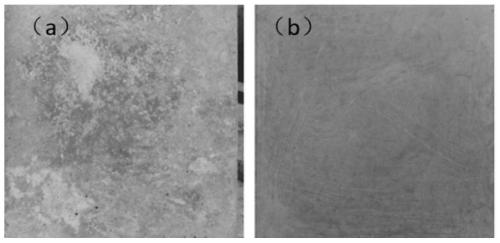

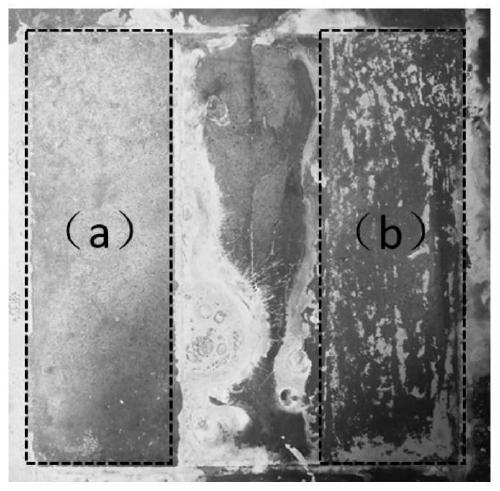

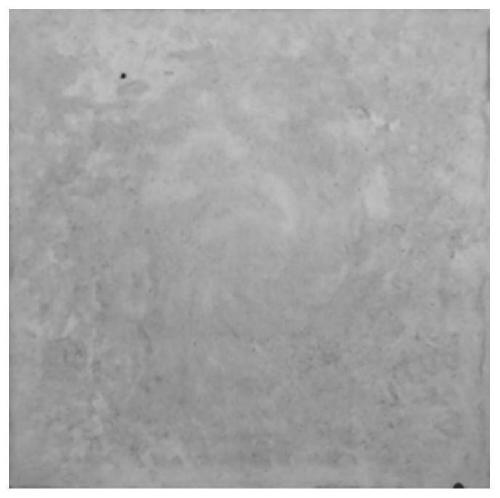

Image

Examples

Embodiment 1

[0022] (1) First, mix 6.65g Span 40 and 140g palm oil evenly, stir at room temperature 20°C for 10 minutes, let it cool naturally, and set aside; mix 3.5g alkylphenol polyoxyethylene ether op-10, 7.35g Sodium dodecylbenzenesulfonate and 191.45g of water were evenly mixed, stirred at room temperature of 20°C for 10 minutes, allowed to cool naturally, and set aside.

[0023] (2) Mix the two liquids in step (1), heat to 40°C, then add 0.35g of xanthan gum and 0.7g of triethanolamine in turn, stir at 40°C for 50 minutes, and let it cool naturally to obtain Release agent.

Embodiment 2

[0025] (1) First, mix 24.6g of Span 40 and 157.5g of palm oil evenly, heat to 40°C and stir for 10 minutes, let it cool naturally, and set aside; mix 10.5g of alkylphenol polyoxyethylene ether op-10 with 156.35 g of water, mixed evenly, heated to 40°C and stirred for 10 minutes, cooled naturally, and set aside.

[0026] (2) Mix the two liquids in step (1), heat to 60°C, then add 0.35g of xanthan gum and 0.7g of triethanolamine in turn, stir at 60°C for 40 minutes, and let it cool naturally to obtain Release agent.

Embodiment 3

[0028] (1) First, mix 6.65g of Span 80 and 140g of palm oil evenly, heat to 40°C and stir for 10 minutes, let it cool naturally, and set aside; mix 3.5g of alkylphenol polyoxyethylene ether op-10, 7.35g Sodium dodecylbenzenesulfonate and 191.45g of water were evenly mixed, heated to 40°C and stirred for 10 minutes, cooled naturally, and set aside.

[0029] (2) Mix the two liquids in step (1), heat to 60°C, then add 0.35g of xanthan gum and 0.7g of triethanolamine in turn, stir at 60°C for 50 minutes, and let it cool naturally to obtain Release agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com