Liquid loading device and control method thereof

A technology of a sample adding device and a control method, which is applied to a measuring device, a lubrication indicating device, and liquid/fluid solid measurement, etc., can solve the problem that the detection accuracy of the immersion photoelectric liquid level sensor decreases, is not suitable for small container liquid level detection, and is not suitable for Large-scale use and other issues, to achieve the effect of quantitative monitoring of sample addition, simple and flexible structure and installation, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

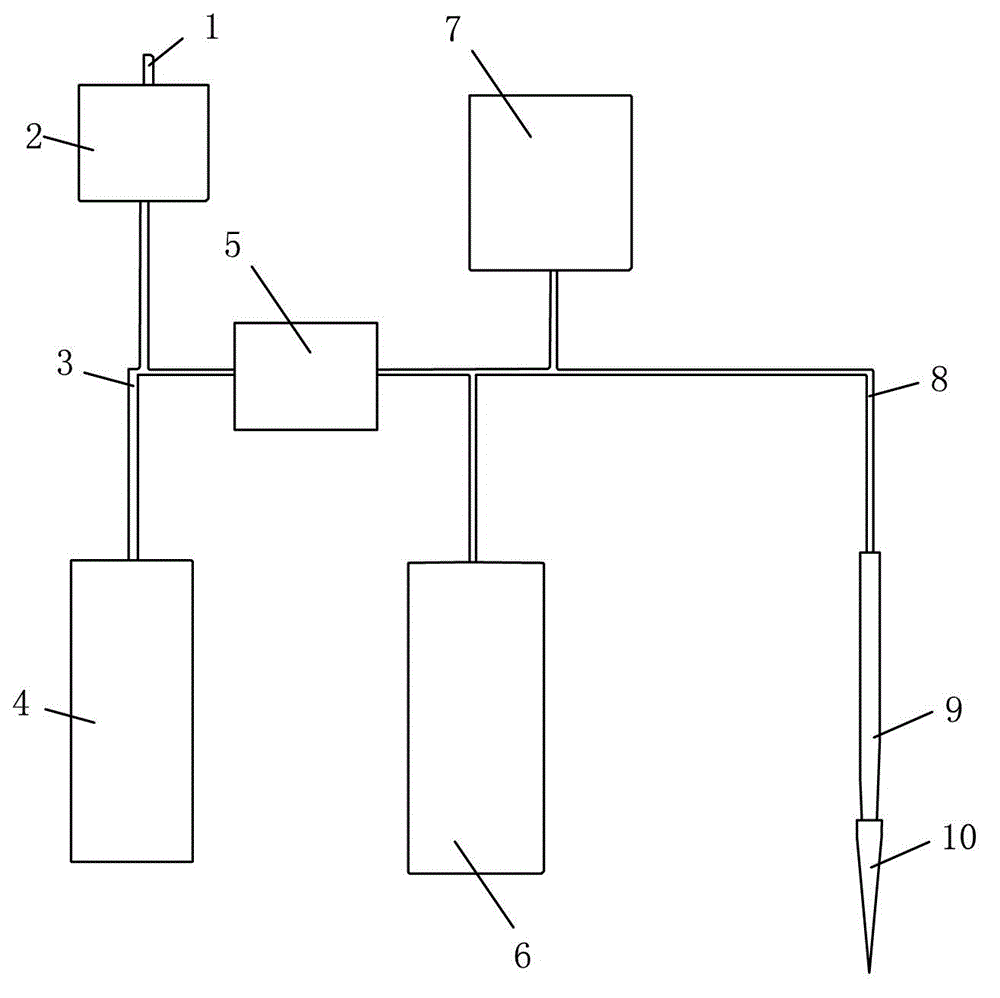

[0041] Please check image 3 , a liquid sampling device, which includes: a hollow sample needle 9, a disposable needle 10 is sleeved on the needle end, the needle tail end of the sample needle 9 is connected to the pipeline 8, and the pressure sensor is connected to the pipeline 8 in sequence 7 and the sample injector 6 are connected to the valve 5. After passing through the valve 5 for a certain distance, the pipeline is divided into two paths, one path is connected to the valve 2, and the other end of the valve 2 is an open end 1; the other path is connected to the pressure syringe 4.

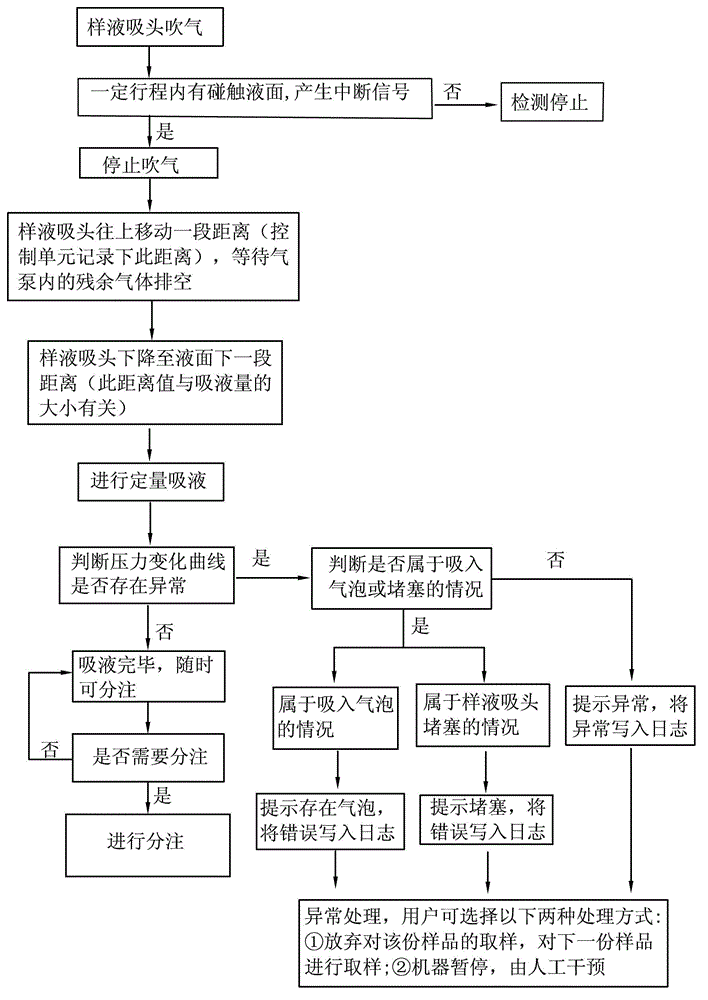

[0042] The working process is as follows: when the sample needle is descending, the valve 5 is opened, the valve 2 is closed, the pressure injector 4 is working, and the sample injector 6 is also working (it is also the action of blowing, or the action of spitting out), and the blowing action is generated, and the sample needle 9 Blow air outward, when the disposable needle 10 on the sample n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com