Supercapacitor sizing manufacturing method

A supercapacitor and slurry technology, which is applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve problems such as imperfect preparation methods, and achieve the effects of good slurry coating performance, increased energy density, and short dispersion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing supercapacitor slurry, the method steps are as follows:

[0042] 1. Weigh LA133 and 20g CMC with a solid content of 50g, add them to 2800g deionized water, and stir for 30min with a vacuum stirrer;

[0043] 2. Add 200g of conductive carbon black while stirring, stir evenly and stir with a vacuum mixer for 30min;

[0044] 3. Then use a high-shear dispersing emulsifier to stir for 10 minutes at a speed of 20000r / min;

[0045] 4. Weigh 730g of activated carbon, add in order while stirring, stir with a vacuum mixer for 30min after stirring evenly;

[0046] 5. Then use a high-shear dispersing emulsifier to stir for 10 minutes at a speed of 20000r / min;

[0047] 6. Vacuumize and stir with a vacuum stirrer for 40 minutes to obtain the supercapacitor slurry.

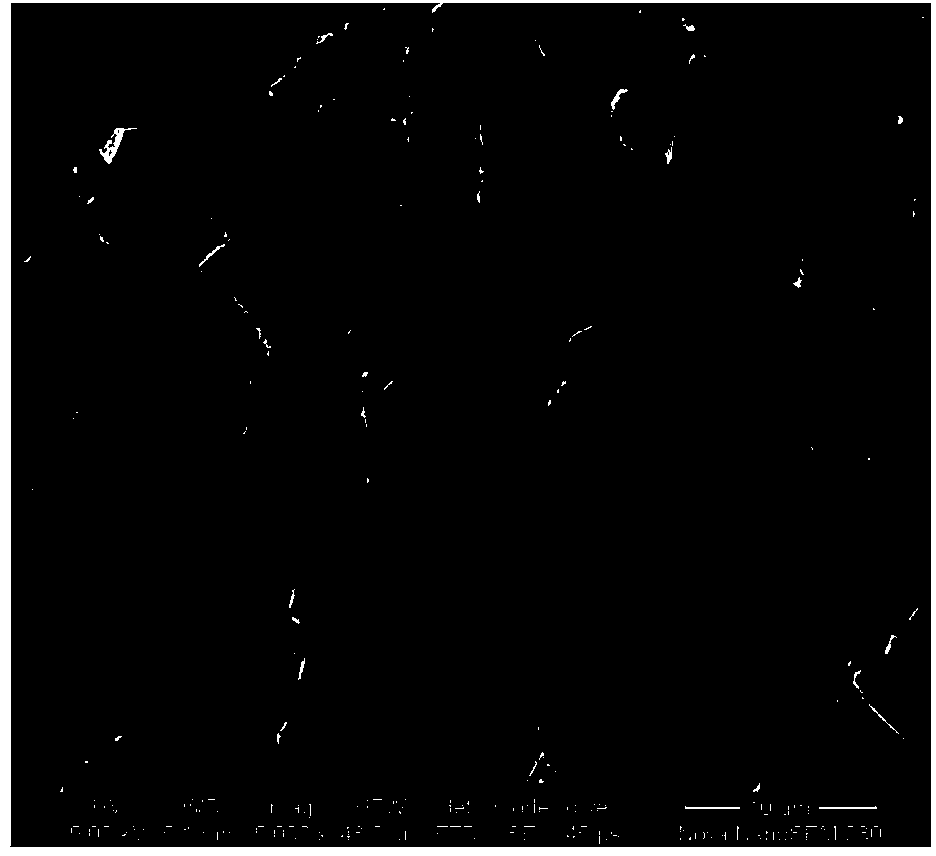

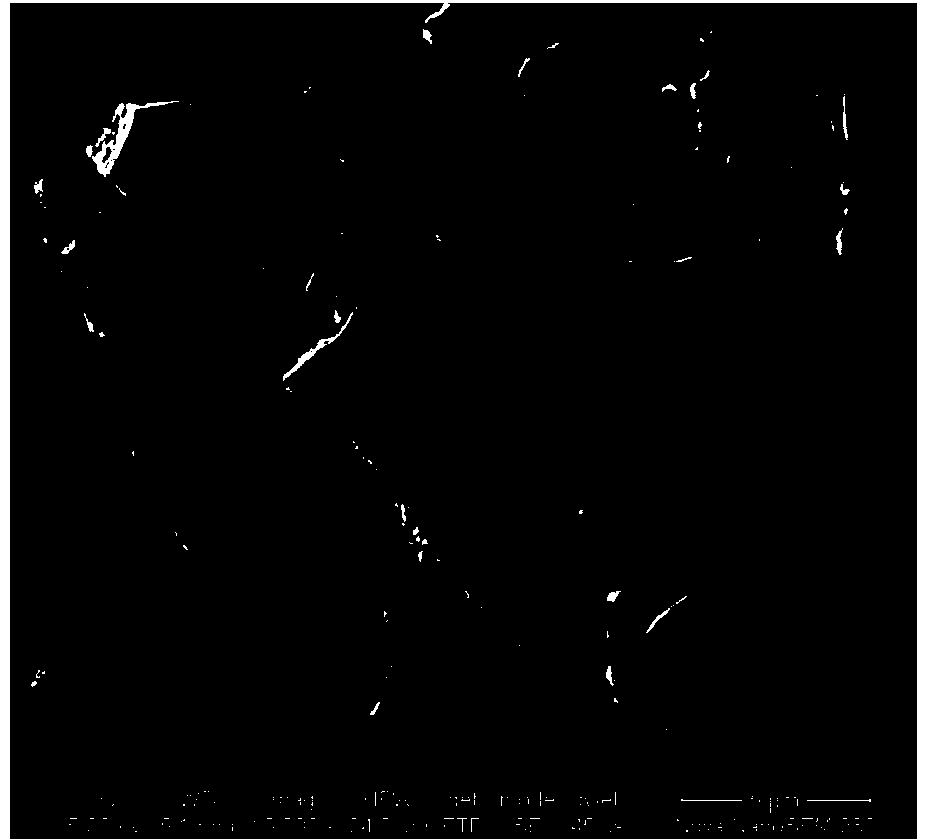

[0048] figure 1 and figure 2 It is a scanning electron microscope (SEM) picture of the slurry. It can be seen from the figure that carbon black is evenly distributed between and on the activate...

Embodiment 2

[0050] A method for preparing supercapacitor slurry, the method steps are as follows:

[0051] 1. Weigh LA132 and 30g CMC with a solid content of 70g, add them to 2600g deionized water, and stir with a vacuum mixer for 30min;

[0052] 2. Add 300g of conductive carbon black while stirring, stir evenly and stir with a vacuum mixer for 30min;

[0053] 3. Then use a high-shear dispersing emulsifier to stir for 10 minutes at a speed of 20000r / min;

[0054] 4. Weigh 600g of ordered mesoporous carbon, add in order while stirring, and stir with a vacuum mixer for 30min after stirring evenly;

[0055] 5. Then use a high-shear dispersing emulsifier to stir for 10 minutes at a speed of 20000r / min;

[0056] 6. Vacuumize and stir with a vacuum stirrer for 40 minutes to obtain the supercapacitor slurry.

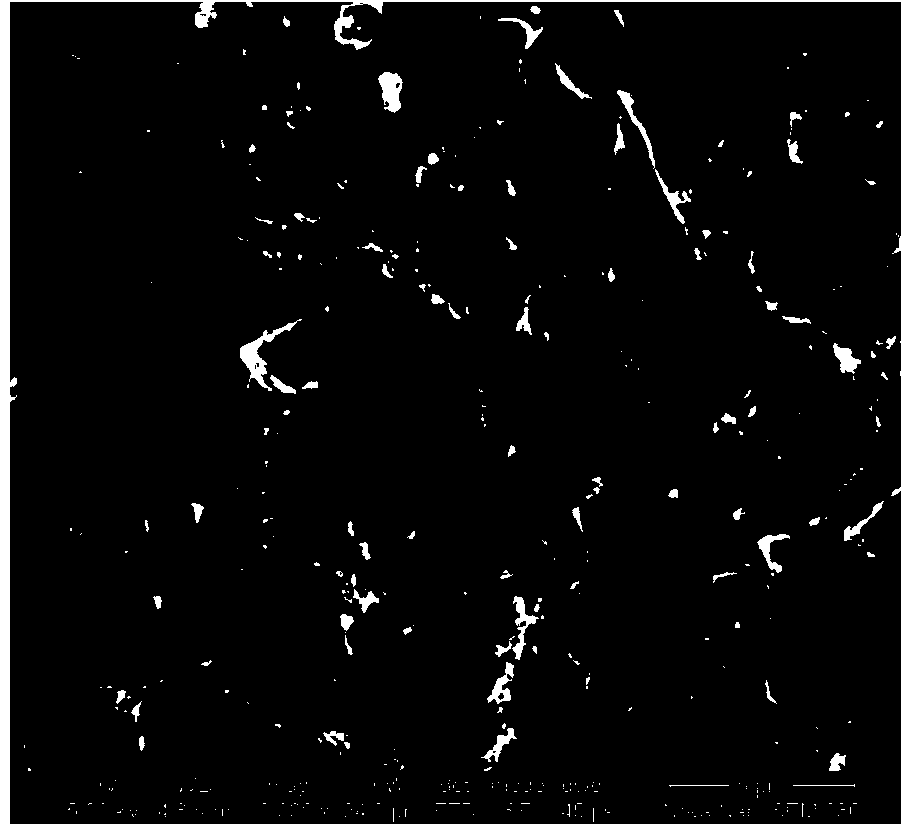

[0057] After SEM testing, it can be observed that the conductive carbon black is evenly distributed on the surface of the ordered mesoporous carbon.

Embodiment 3

[0059] A method for preparing supercapacitor slurry, the method steps are as follows:

[0060] 1. Weigh LA133 with a solid content of 4g and 1g of CMC, add it to 280g of deionized water, and stir for 10 minutes with a vacuum stirrer;

[0061] 2. Add 10g of conductive carbon black while stirring, stir evenly and then stir with a vacuum mixer for 10min;

[0062] 3. Then use a high-shear dispersing emulsifier to stir for 2 minutes at a speed of 20000r / min;

[0063] 4. Add 85g of graphene while stirring, stir evenly and stir with a vacuum mixer for 10min;

[0064] 5. Then use a high-shear dispersing emulsifier to stir for 5 minutes at a speed of 20000r / min;

[0065] 6. Vacuumize and stir with a vacuum stirrer for 20 minutes to obtain the supercapacitor slurry.

[0066] After SEM testing, it can be observed that the conductive carbon black is evenly distributed on the graphene surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com