Precision casting device and process for eliminating molten metal bubbles during casting

A technology of molten metal and precision casting, applied in metal processing equipment, molds, mold components, etc., can solve the problems of bubbling, increased casting costs, unqualified blanks, etc., to eliminate the generation of metal bubbles, reduce casting cost, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

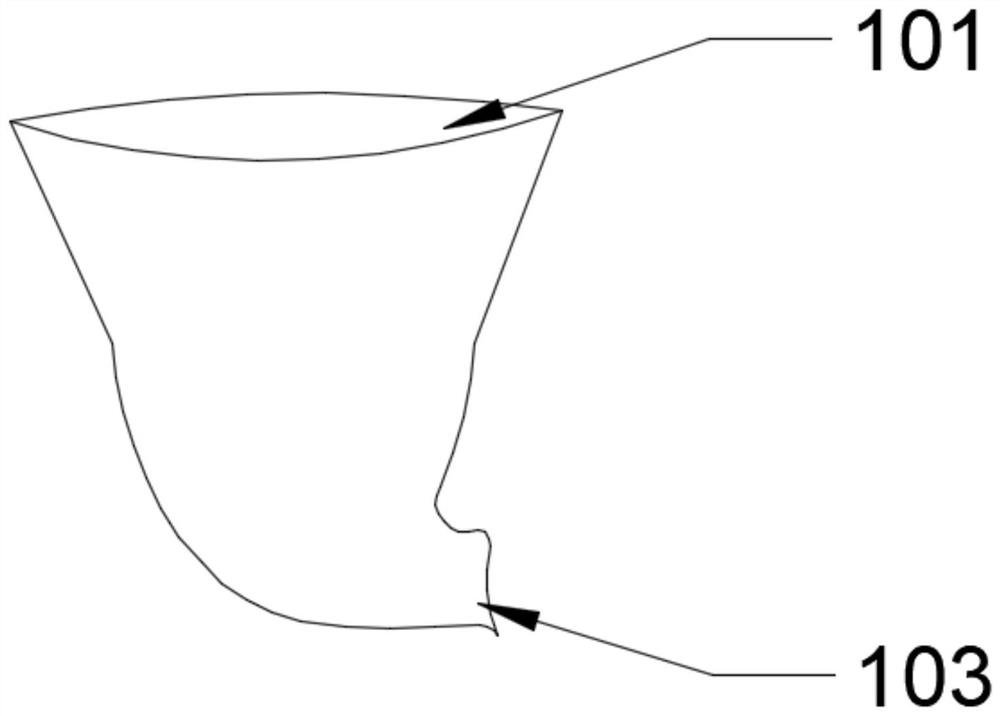

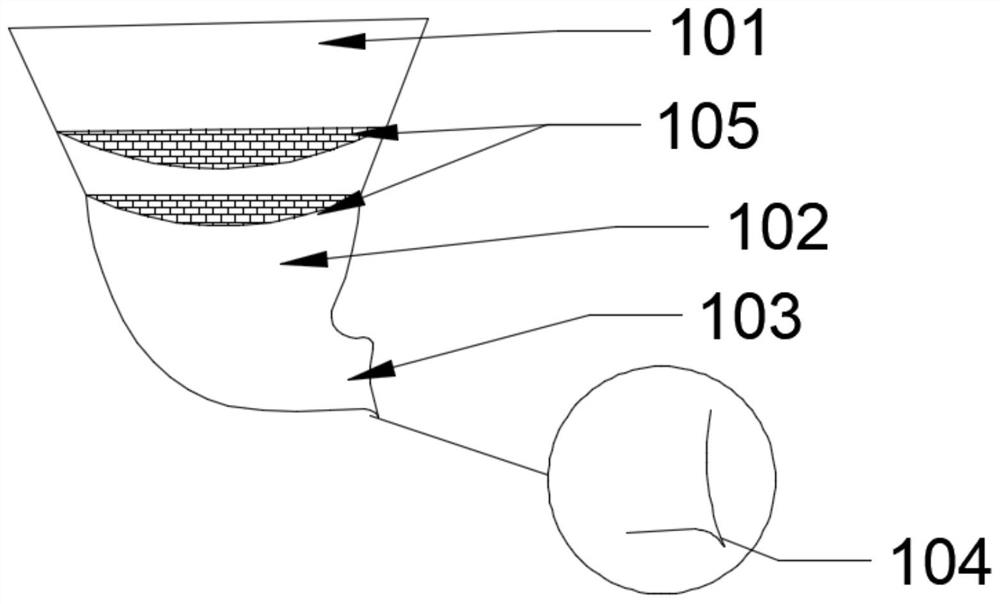

[0032] Example 1, such as figure 1 and figure 2 A precision casting device that eliminates the metal liquid bubble in casting, including the liquid pipe 101, the bottle body 102, and the liquid opening 103, the liquid liquid opening 101 is inverted funnel shape, the bottle body 102 lumen wall is smooth, and the body 102 The inner cavity side wall is a cylindrical structure, and the longitudinal transverse arc shape is smooth, the curve is smooth, and the liquid port 103 is disposed laterally in the outlet direction of the bottle body 102, the bottle body 102 and the solution Two-layer filter mesh 105 is provided between the mouth 102 in the mouth 102.

[0033] The liquid opening 103 is provided with a duck-type liquid tunnel 104 that is lifted at the lower end, and the liquid tunnel 104 is from 30-45 ° in the horizontal direction angle, and the effect is best in 45 °.

[0034] In the two-layer filter mesh 105, the upper filtration mesh 105 is more coarse, two-layer filter grid 105...

Embodiment 2

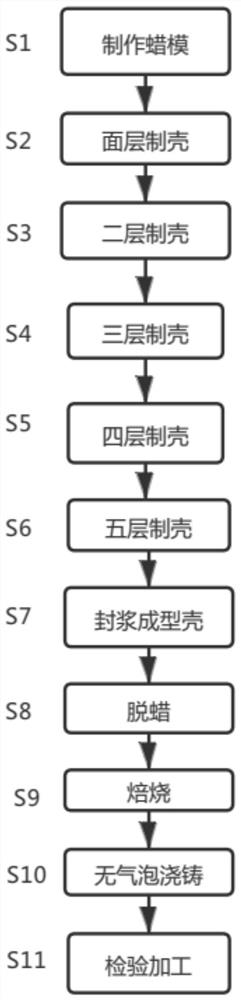

[0036] Example 2, such as image 3 As shown, a precision casting process that eliminates metal liquid bubbles in castings, including the following steps:

[0037] Step 1: Making a wax mold: Select quantitative low temperature white wax heating and elimination as a membrane while heats the moisture polyethylene and incorporates the mold, and stirred in the incubator of 53-65 ° C, take out, and cool, In the clean environment, the waxing machine is carried by wax according to the drawings, and the wax mold is cleaned, dry, and form a wax mold using a neutral cleaning liquid.

[0038] Step 2: Side shell: Extract 330 mesh sand, a plateau mortar made of 330 meteori sand, uniform spray 90-130 mesh sand, forming 90-130 mesh sand The surface shell, and maintain a clean environment, temperature 24 ± 2 ° C, naturally dry;

[0039]Step 3: Two-layer shell: Wipe 330 mesh sands on the surface of the surface shell, the viscosity of 23-26 MPa.s, is sprayed 90-130 mesh plateau sand, forming a second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com