Device and method for testing energy release of active material under different atmospheres

A technology for active materials and testing devices, applied in measurement devices, analytical materials, strength properties, etc., can solve problems such as inaccurate testing, difficulty in conducting experiments, and difficulty in controlling the loading size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

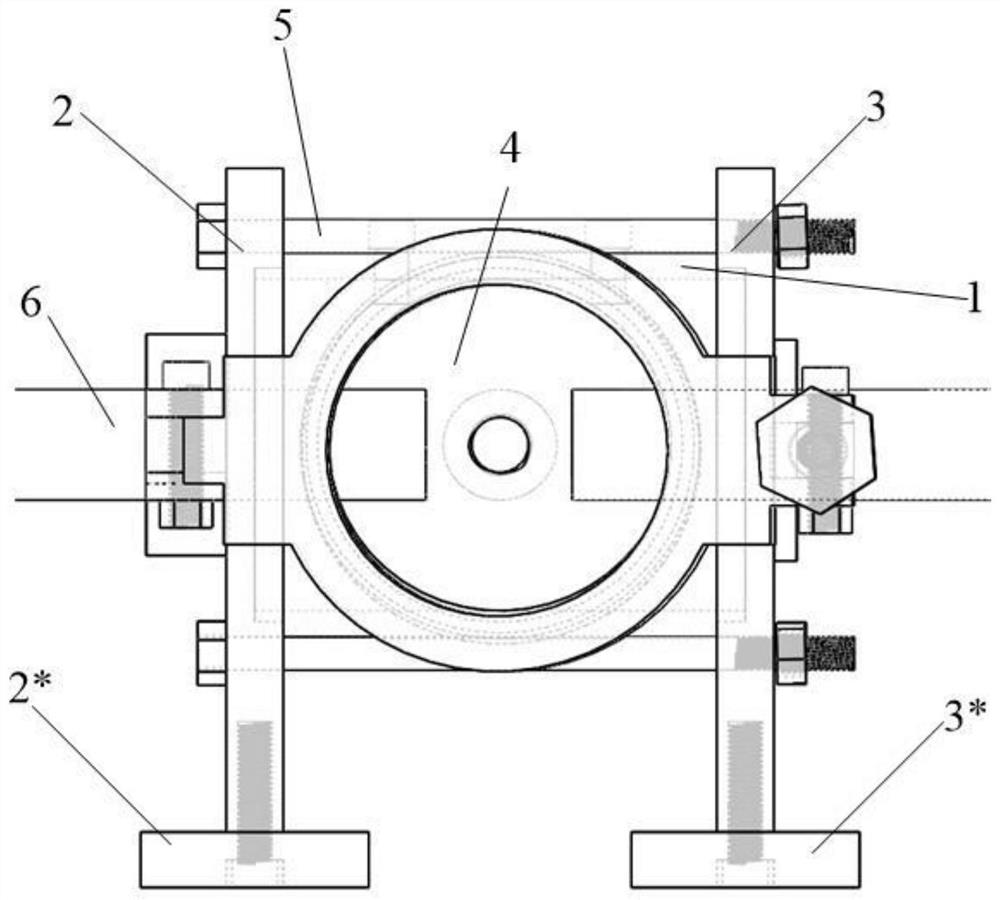

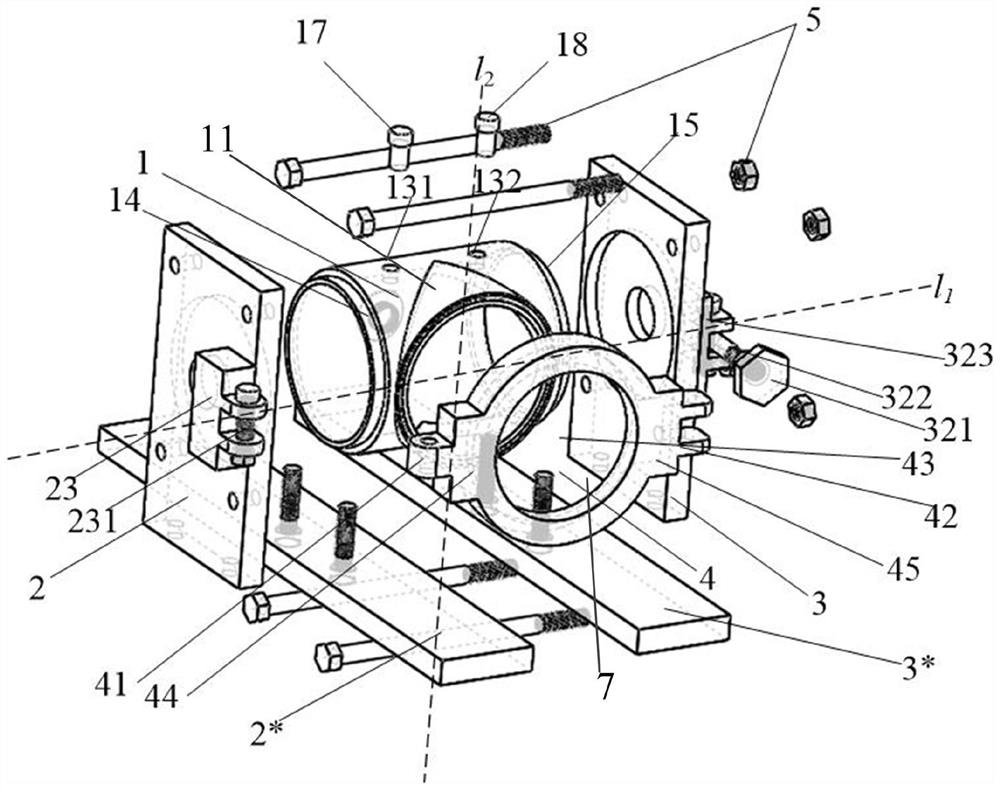

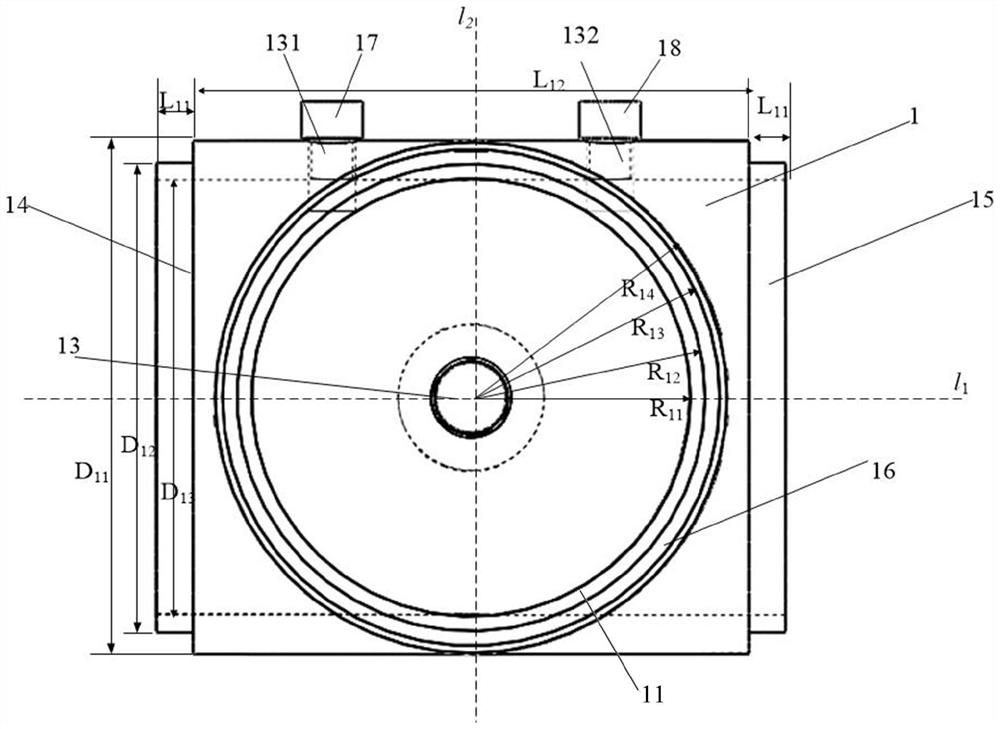

[0055] The present invention will be further described below in conjunction with accompanying drawing:

[0056] Such as figure 1 with figure 2 As shown, the present invention has a cylindrical shape with two side walls as a whole, a hinge is installed on one side wall, and a buckle is installed on the other side wall. Define one end of the side wall with the hinge as the left end, and one end of the side wall with the buckle as the right end. The present invention is made up of main tank body 1, left supporting wall 2, left supporting base 2*, right supporting wall 3, right supporting base 3*, observation window 4, fixed screw rod 5, and pressure sensor, camera and Hopkinson pressure bar 6 used together. The main tank body 1 is sandwiched between the left support wall 2 and the right support wall 3, above the left support base 2* and the right support base 3*, the central axis 1 of the main tank body 1 1 It is perpendicular to the left supporting wall 2 and the right supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com