Patents

Literature

199 results about "Trichlorohydrin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trichlorohydrin. Identifiers CAS Number. ... 1,2,3-Trichloropropane (TCP) is a chemical compound that was an impurity in 1,3-dichloropropene fumigants manufactured by Shell Chemical Company and Dow Chemical Company. Exposure by inhalation, skin contact, or ingestion can be harmful to health

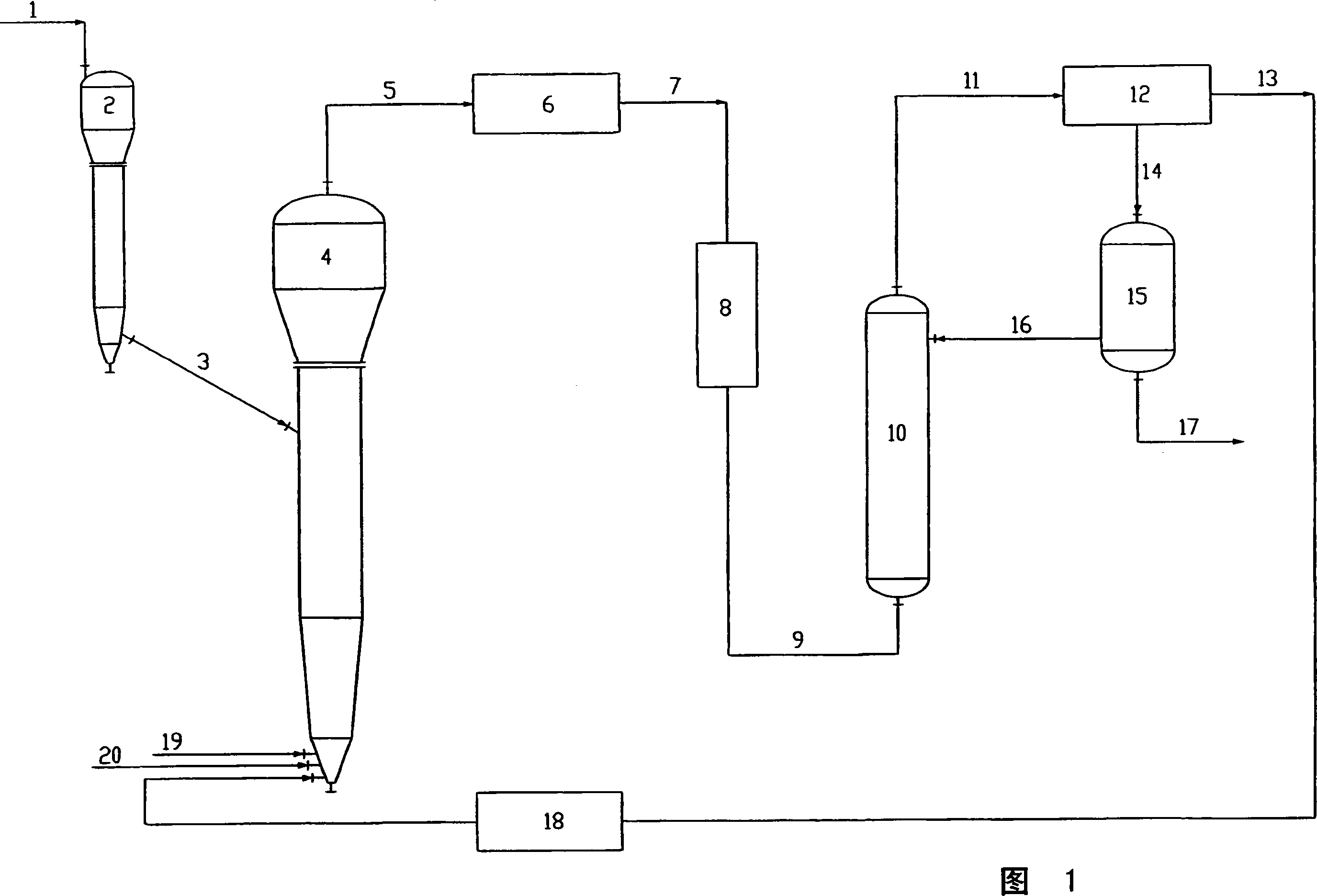

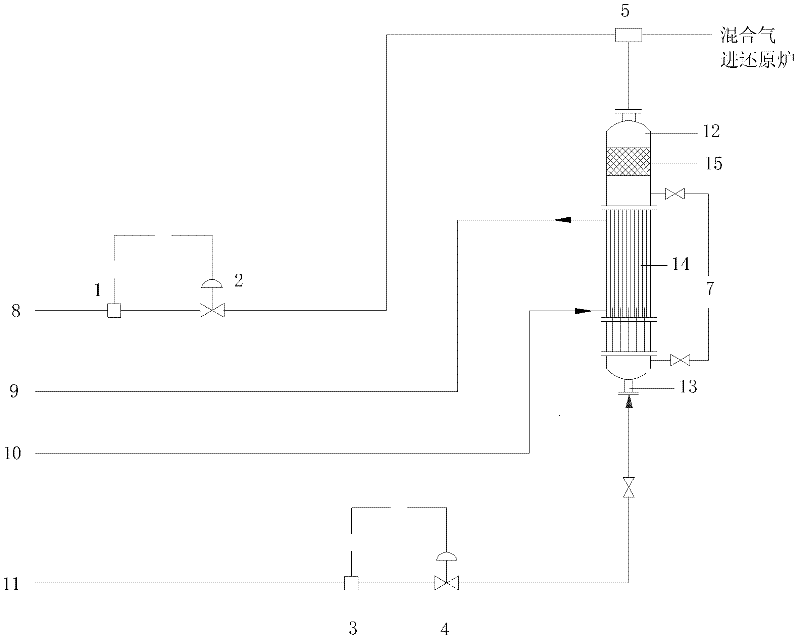

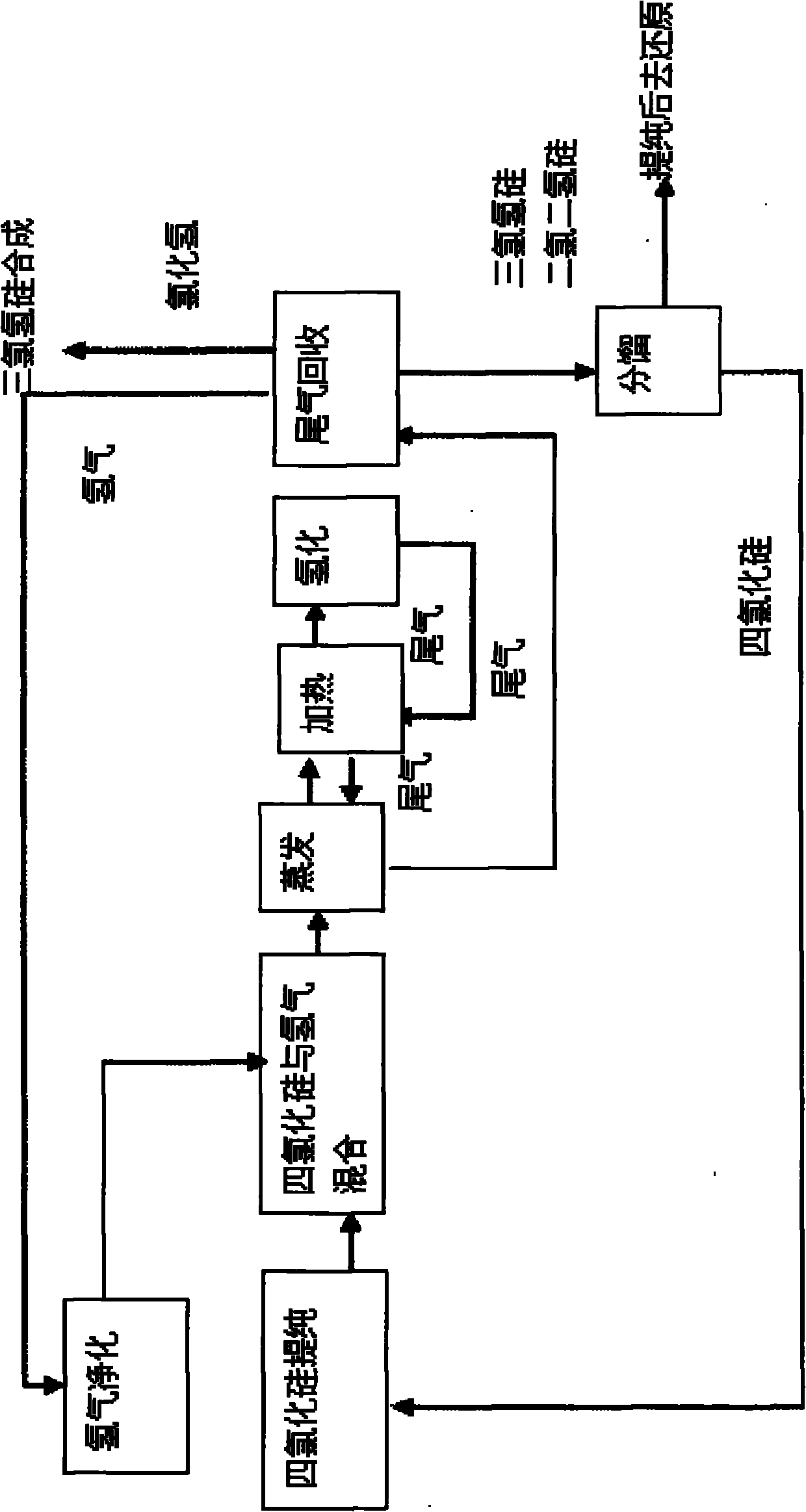

Modified method and device for preparing trichlorosilane and multicrystal silicon

The invention relates to an improved method and equipment for the preparation of trichlorosilane and polysilicon. The trichlorosilane is prepared by a chlorine hydrogenation method during the preparation process of polysilicon. The process is as follows: a) the metallurgical silicon is put into a reactor after being heated to 300-500DGE C in a powder baker; b) the silicon tetrachloride is vaporized and heated through an external heating device, which generates the silicon tetrachloride gas at the temperature of 160-600DGE C; c) the hydrogen chloride gas is preheated to 150-300DGE C through the external heating device; d) the hydrogen gas is preheated to 300-600DGE C through a heater; and e) the gases of step b), c) and d) are added into the reactor; wherein, the molar ratio between the hydrogen gas and the silicon tetrachloride is 1-5:1, the molar ratio between the hydrogen chloride gas and the silicon tetrachloride is 1: 1-20; and the temperature in the reactor is maintained at 400-600DGE C and the pressure in the reactor is kept at 1.0-3.0MPa. The method of the invention can effectively prepare the polysilicon at a low cost, which suits for semiconductor industry and solar battery.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV +1

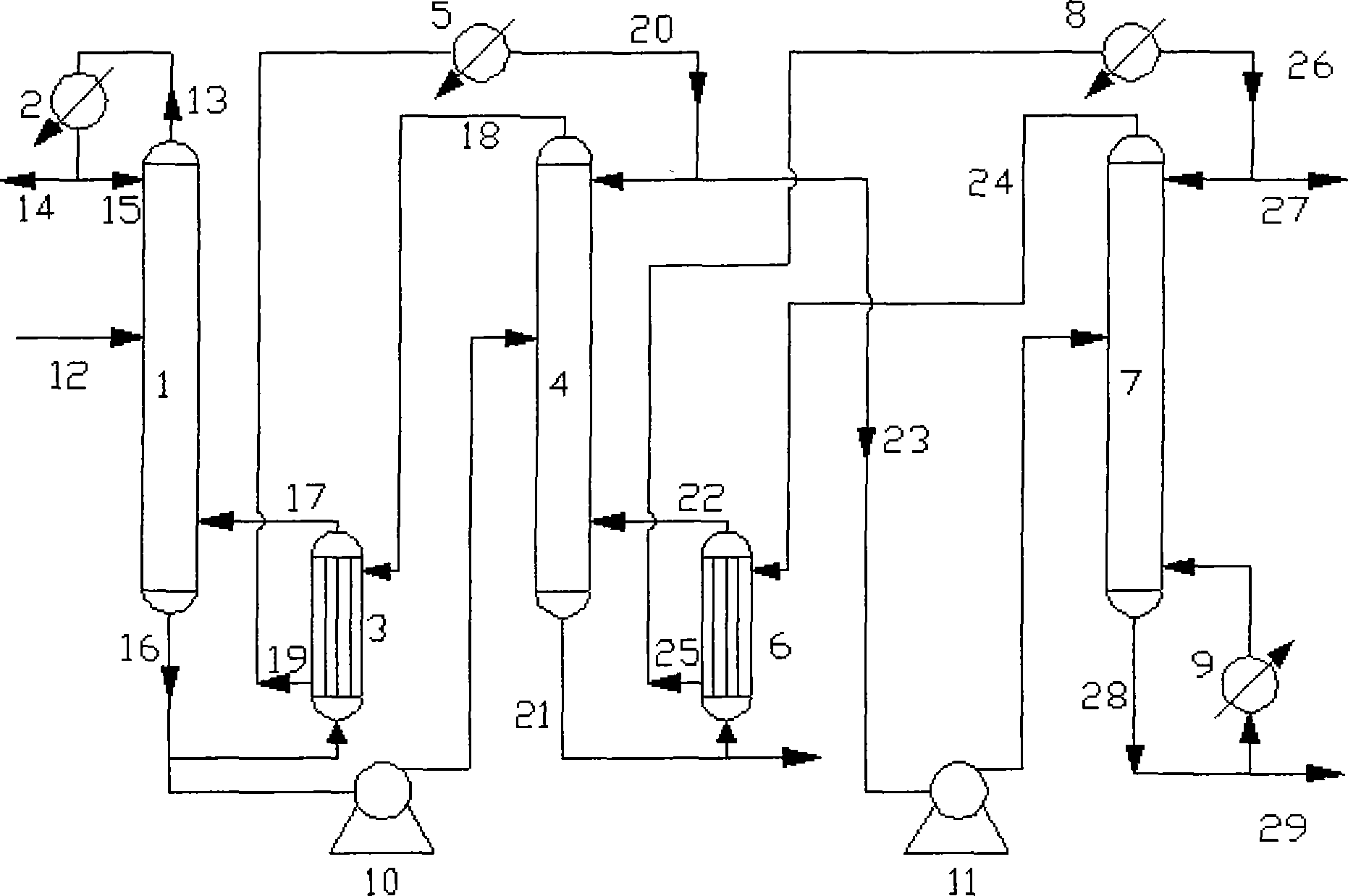

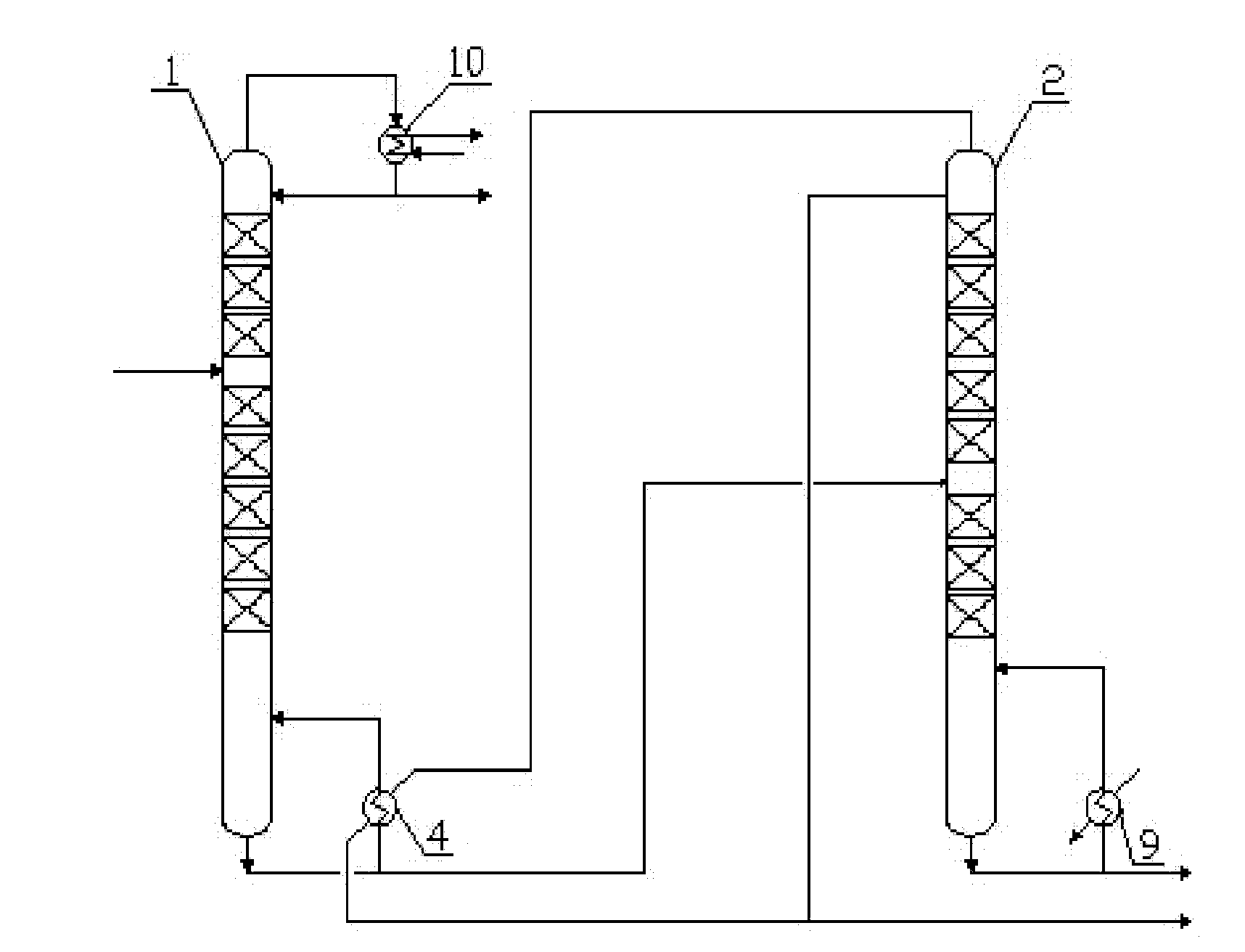

Trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system and operating method

ActiveCN101786630ASave heating and energy saving lossReduce cooling loadChemical industryHalogenated silanesDifferential pressureProcess engineering

The invention relates to a trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system and an operating method. The trichlorosilane three-tower differential pressure coupling energy-saving rectifying and purifying system comprises a primary tower, a secondary tower and a tertiary tower; the three towers are connected in series from low pressure to highpressure or from high pressure to low pressure, and a condensation re-boiler is arranged between the primary tower and the secondary tower and between the secondary tower and the tertiary tower respectively; and the three towers can be used for light removal, heavy removal and light removal in turn, and also can be used for combining light removal, heavy removal and light removal. According to the characteristics of approach full tower composition and approach temperature in the process of rectifying the trichlorosilane, the invention provides a trichlorosilane differential pressure coupling rectifying process which is expected to greatly reduce the production cost and energy consumption and theoretically rectify and save energy by nearly 70 percent. The technology remarkably improves themarket competitiveness of polycrystal silicon materials and promotes the development of a photovoltaic and information material industry chain.

Owner:TIANJIN UNIV

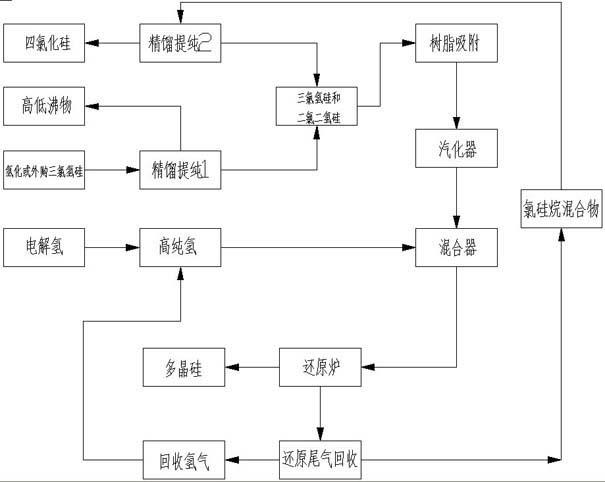

Method adopting trichlorosilane and dichlorosilane mixed raw materials to produce polycrystalline silicon

InactiveCN102642834ASolve processing problemsReduce investmentSiliconPhysical chemistryMixed materials

The invention discloses a method adopting trichlorosilane and dichlorosilane mixed raw materials to produce polycrystalline silicon. After trichlorosilane produced by hydrogenation of silicon tetrachloride or purchased outside is rectified and purified, the rectified and purified trichlorosilane is mixed with recycled trichlorosilane and dichlorosilane mixed materials, the volume percent of dichlorosilane in the mixed raw materials is controlled to be between 3% and 15%, preferably between 5% and 10%, then impurity removal by adsorption and vaporization operation are performed, vaporized chlorosilane mixed gas and high-purity hydrogen are mixed according to mole ratio of 1:2 to 1:10, preferably 1:4 to 1:6, and finally the vaporized chlorosilane mixed gas and the high-purity hydrogen enter into a reduction furnace to produce the polycrystalline silicon. After reactions, tail gas undergoes low-temperature condensation recycle, chlorosilane obtained by recycle is sent to a rectification process to perform separation of silicon tetrachloride and impurities, and the trichlorosilane and dichlorosilane mixed raw materials are obtained. The method makes full use of byproduct dichlorosilane in the polycrystalline silicon production process to improve sedimentation velocity of silicon and reduce power consumption and material consumption, simultaneously can reduce treatment cost and loss of silicon, and improves trichlorosilane utilization rate.

Owner:雅安永旺硅业有限公司

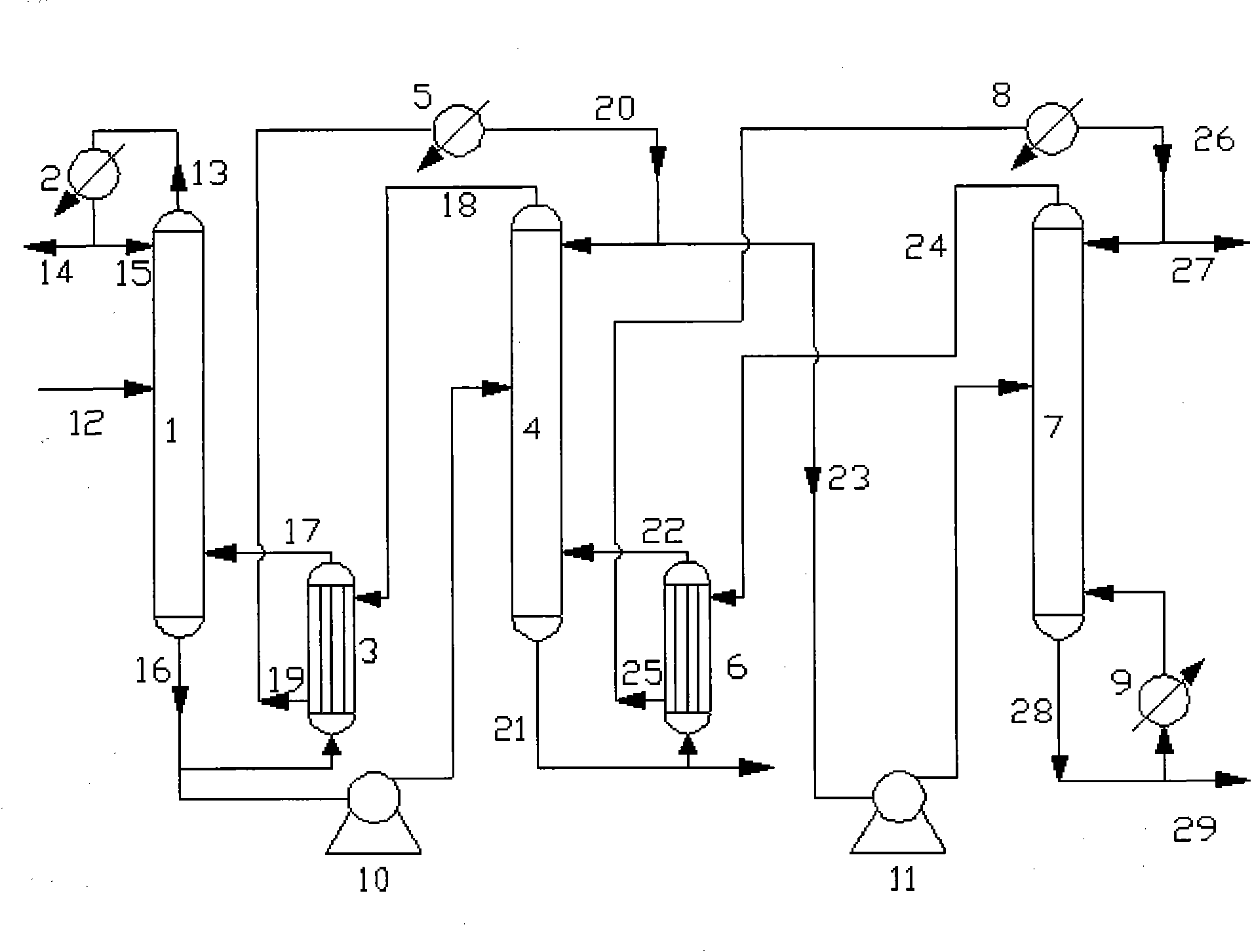

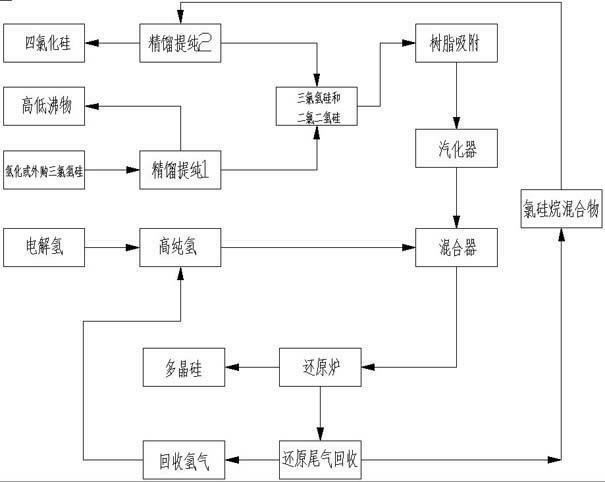

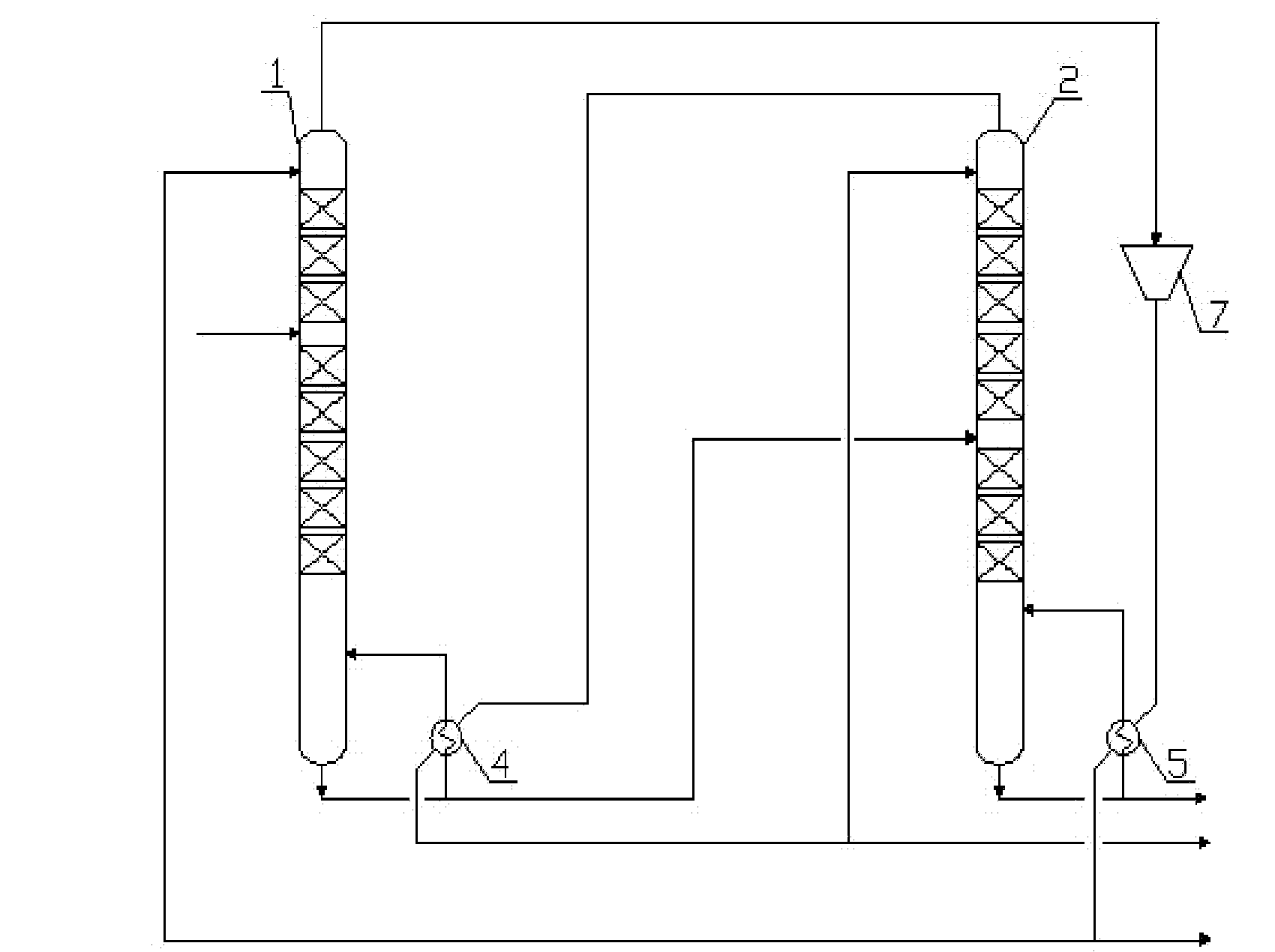

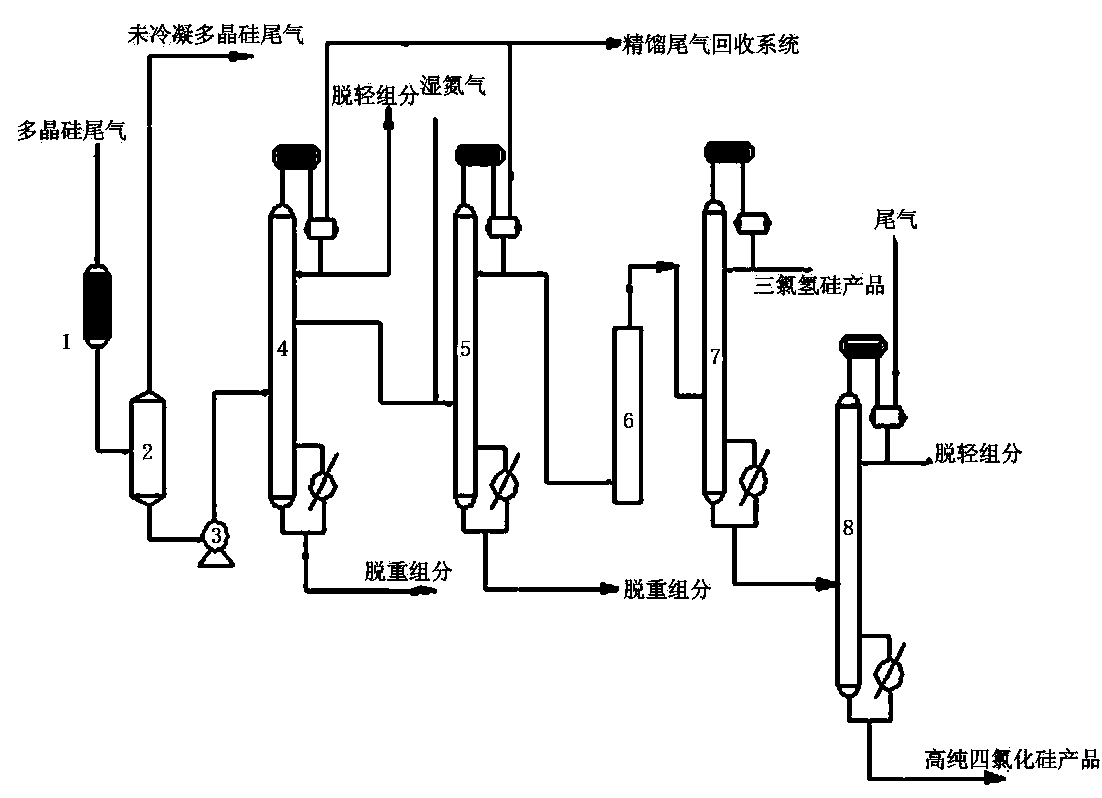

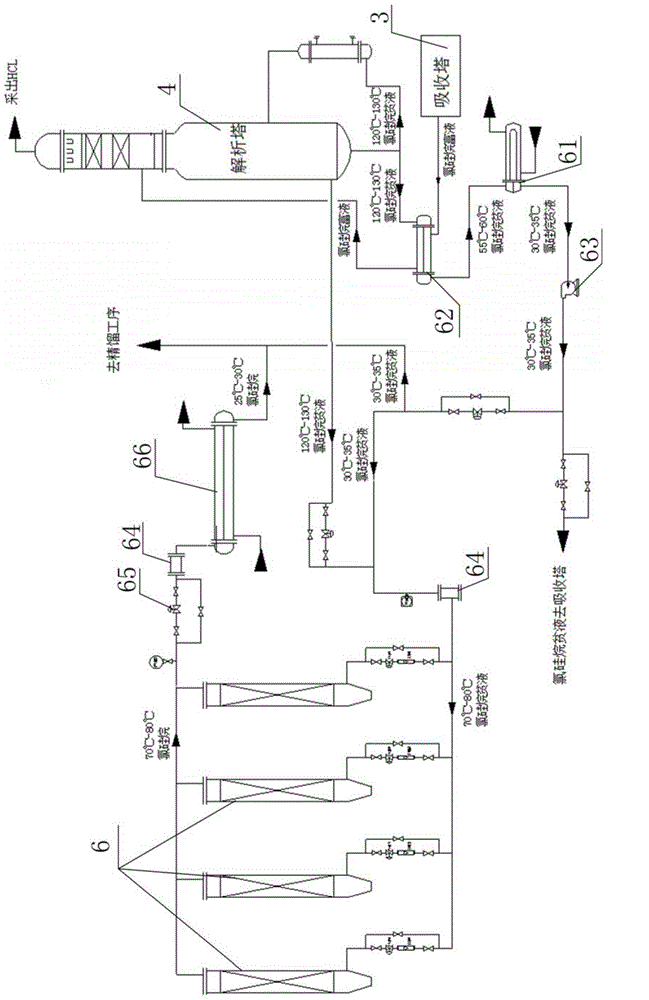

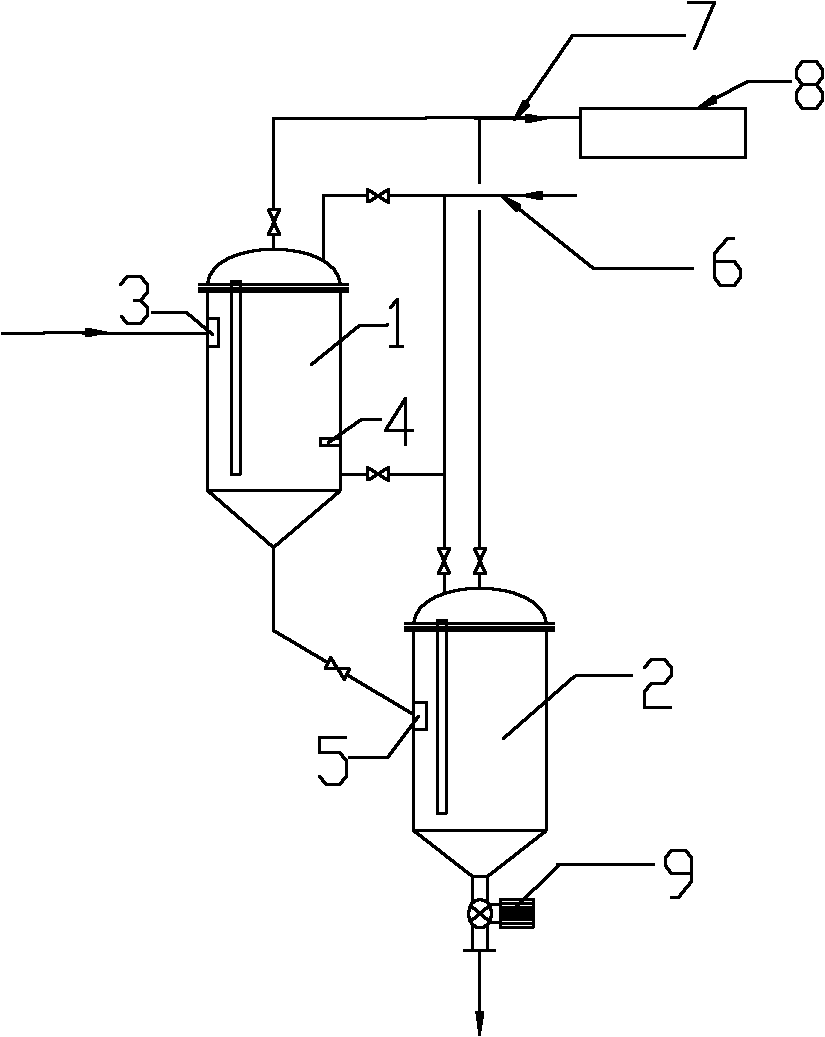

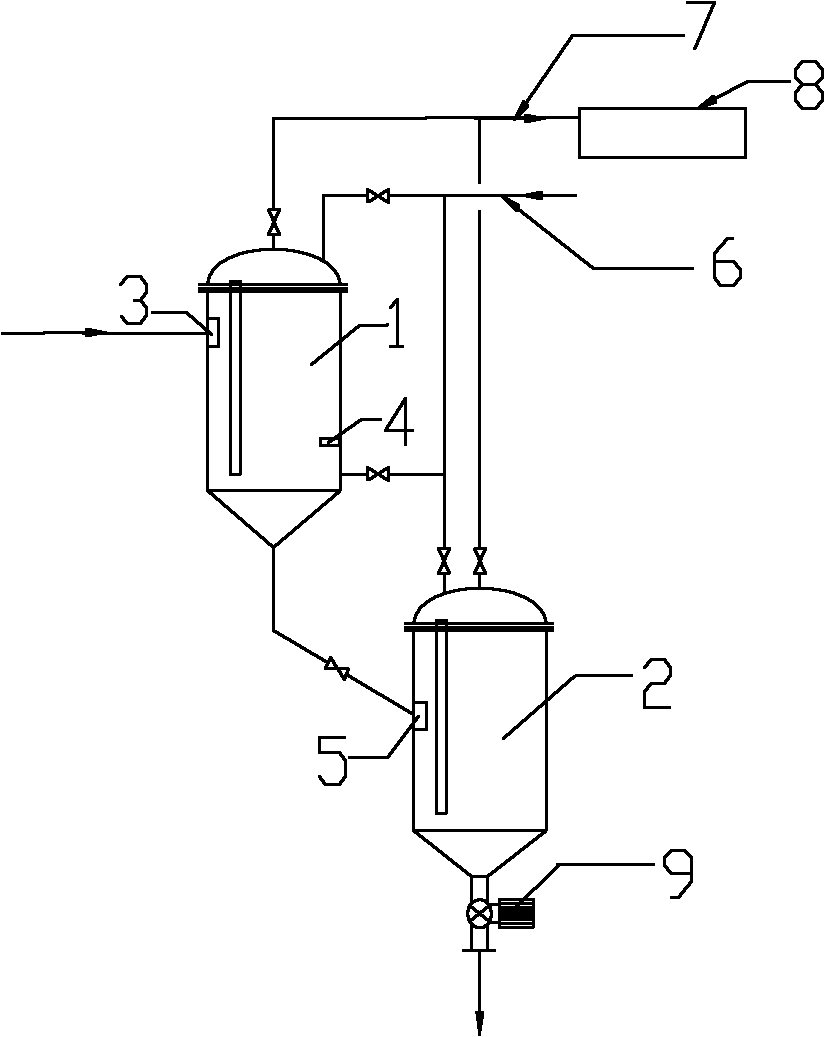

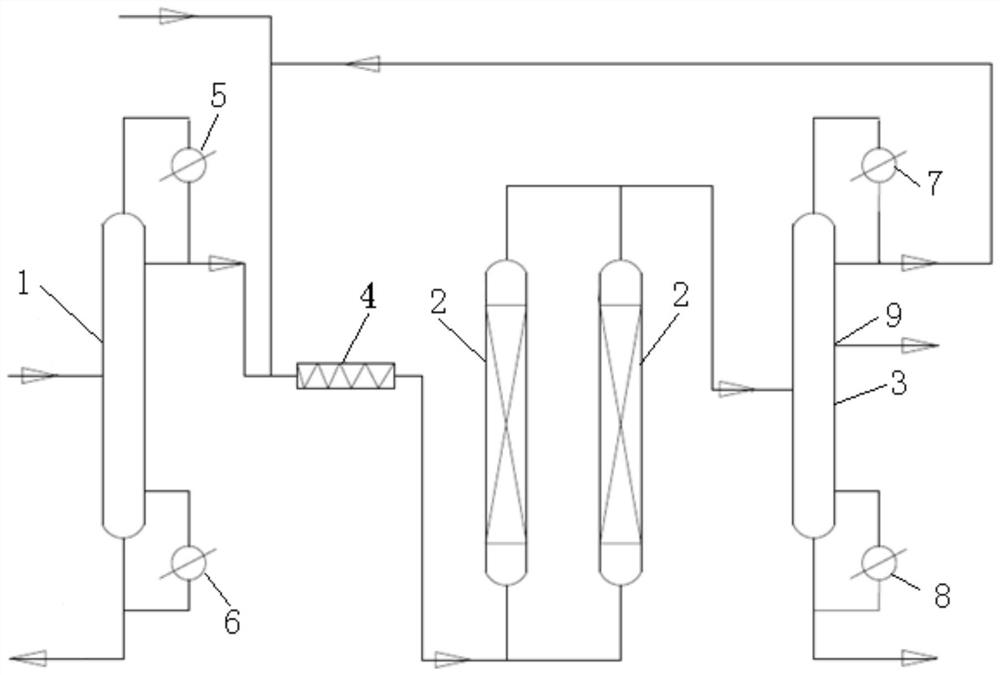

System for separating and purifying trichlorosilane in production process of polysilicon and operation method thereof

ActiveCN101538044ALow impurity contentMeet production requirementsChemical industryHalogenated silanesProcess engineeringTower

The invention provides a system for separating and purifying trichlorosilane in production process of polysilicon and an operation method thereof. The system consists of a rectification working section and a recovery refining working section; wherein, the rectification working section comprises six towers, and the recovery refining working section includes three towers; the connection mode of the six towers of the rectification working section is that a lightness-removing tower I, a lightness-removing tower II, a weight-removing tower, a secondary lightness-removing tower, a secondary weight-removing tower I and a secondary weight-removing tower II are sequentially connected with each other; the connection mode of the three towers of the recovery refining working section is that a lower-removing tower, a higher-removing tower and a product refining tower are sequentially connected with each other. Chlorsilane rectification technical equipment can be one of main technical bottlenecks limiting the production of the high-quality polysilicon material in China. The invention can achieve the separation requirements and energy-saving aim under the condition that the mass flow rate elastic ratio between feeding of the rectification working section and feeding of the recovery working section is 1:1-1:5. The rectification technique is simplified and optimized, the separation efficiency is improved, the energy consumption of rectification products is reduced, the reliability and stability of system operation can be enhanced, and the content of phosphorus, arsenic, boron and metallic contamination in the rectification products can be lowered.

Owner:TIANJIN UNIV

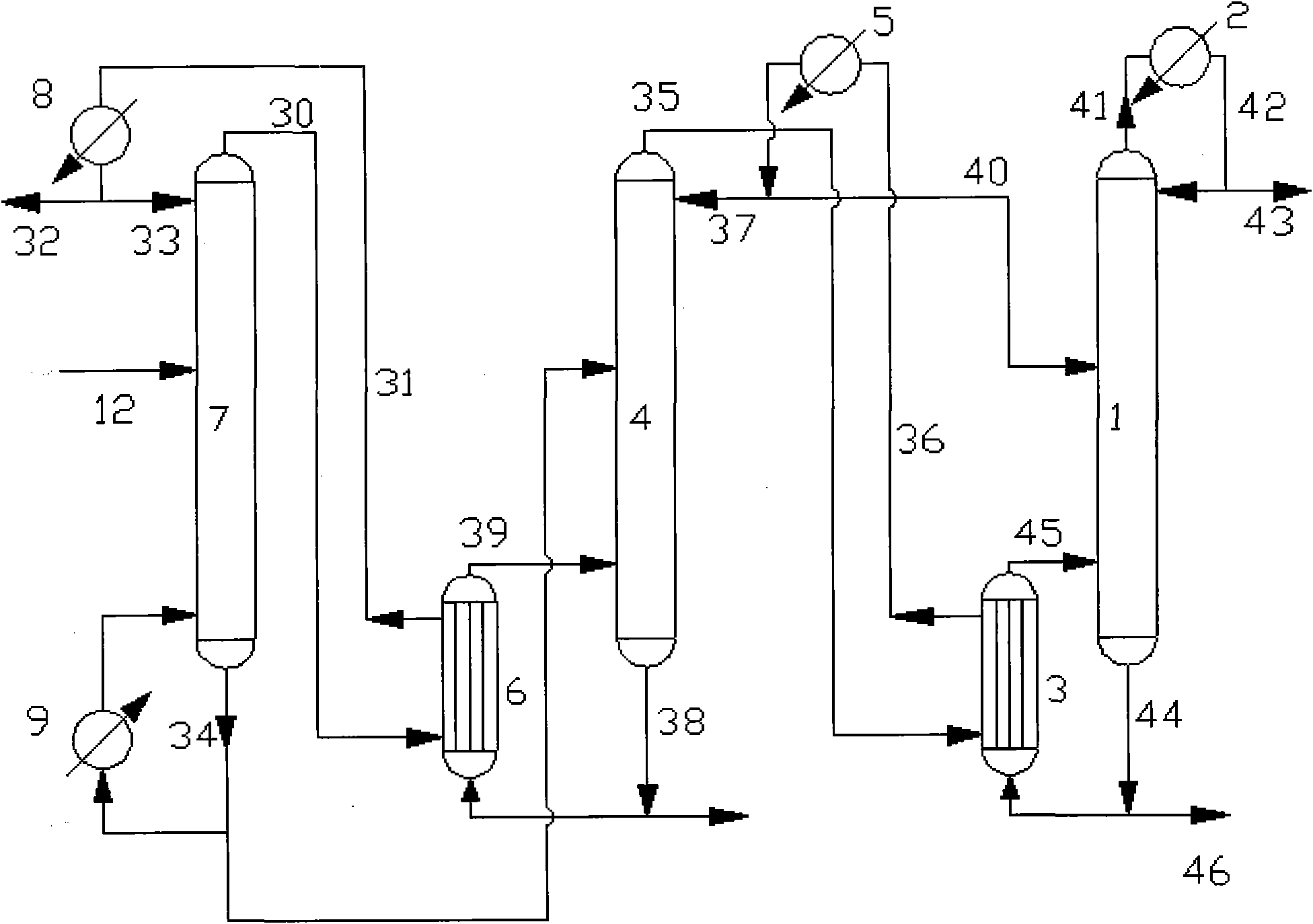

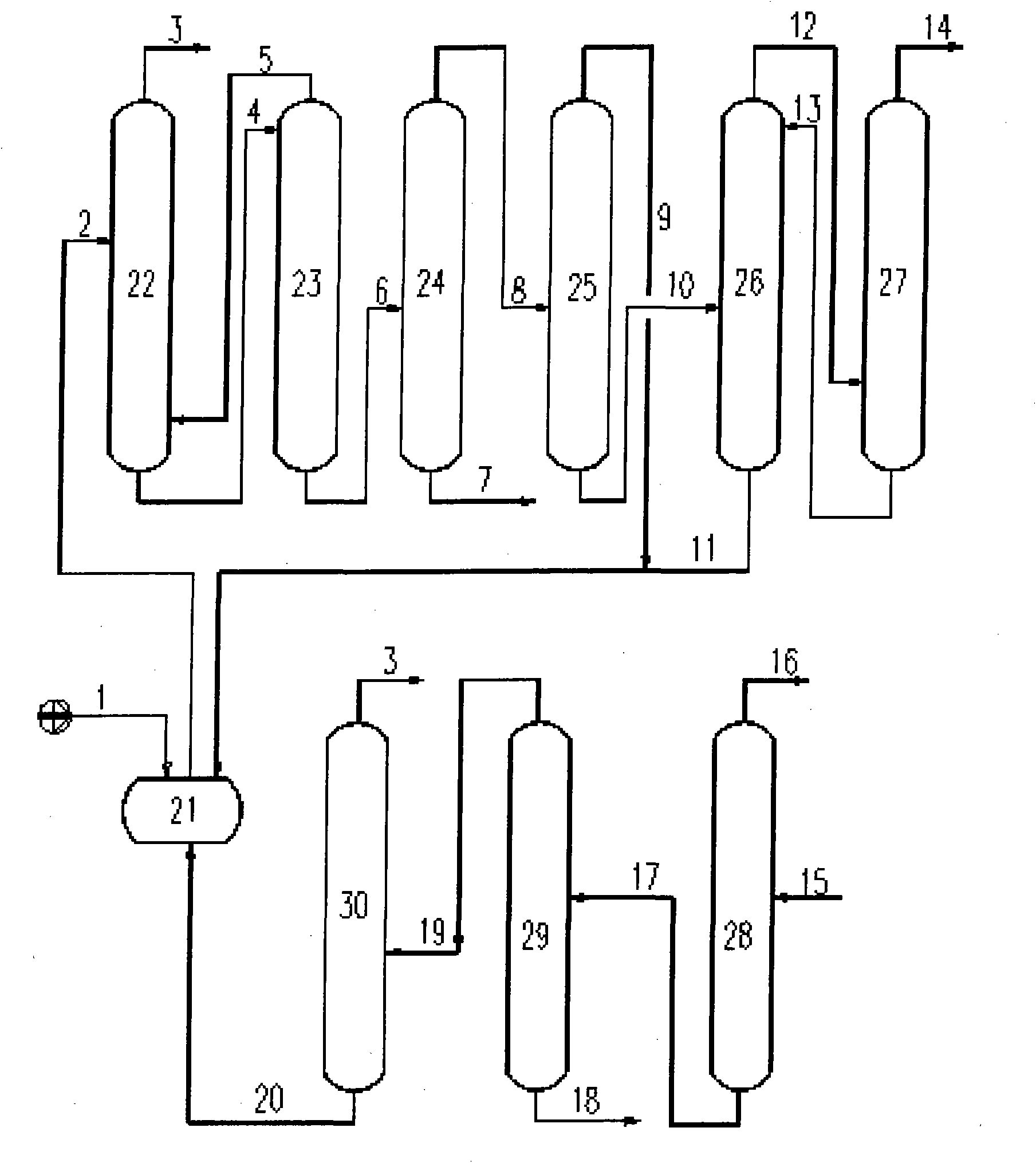

Heat pump distillation and multi-effect distillation integrated device and process for purifying trichlorosilane

InactiveCN102153092AReduce energy consumptionIncrease power consumptionEnergy inputHalogenated silanesElectricityReboiler

The invention discloses a heat pump distillation and multi-effect distillation integrated device and process for purifying trichlorosilane. The steam at the top of a high-pressure tower which is a high-boiling-fraction removal column is used to heat liquid at the bottom of a low-pressure tower which is a low-boiling-fraction removal column, the steam at the top of the high-boiling-fraction removal column is condensed, and the process is a multi-effect distillation process; meanwhile, the steam at the top of the low-boiling-fraction removal column is subjected to pressure and temperature rise through a compressor and then is used for heating the liquid at the bottom of the high-boiling-fraction removal column, the steam at the top of the low-boiling-fraction removal column is condensed, and the process is a heat pump distillation process; and the integration of the heat pump distillation and multi-effect distillation can be realized in the whole process. In the whole process flow, one compressor is additionally arranged, the heat exchange process inside a rectification system is realized by two heat exchangers and condensers and reboilers are saved simultaneously, that is to say, small amount of electricity consumption of one compressor is added and a large amount of cold energy and heat public works are saved, and thereby the energy consumption for the whole rectification and purification process of the trichlorosilane is greatly reduced.

Owner:TIANJIN UNIV

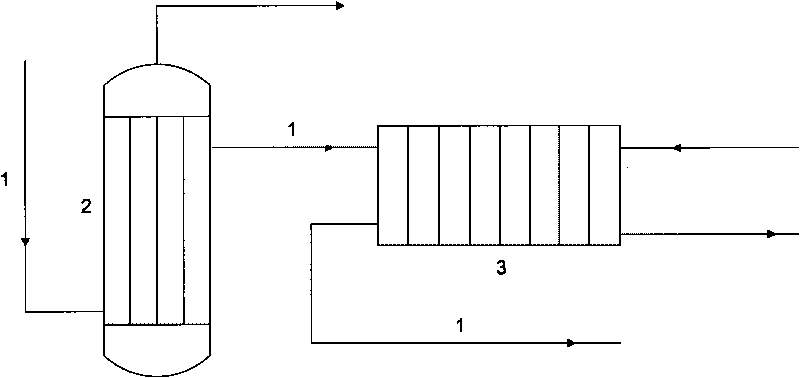

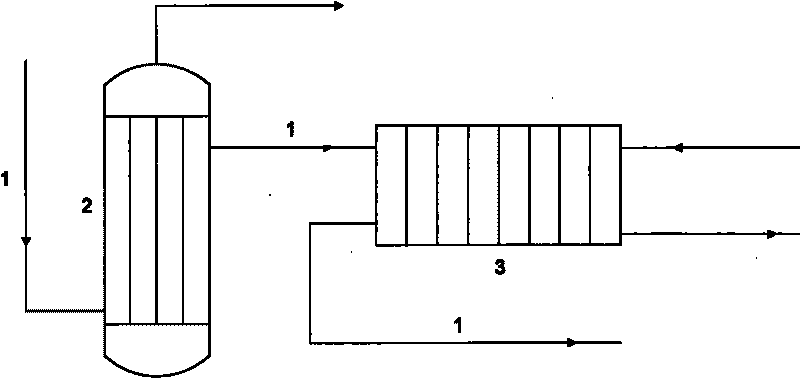

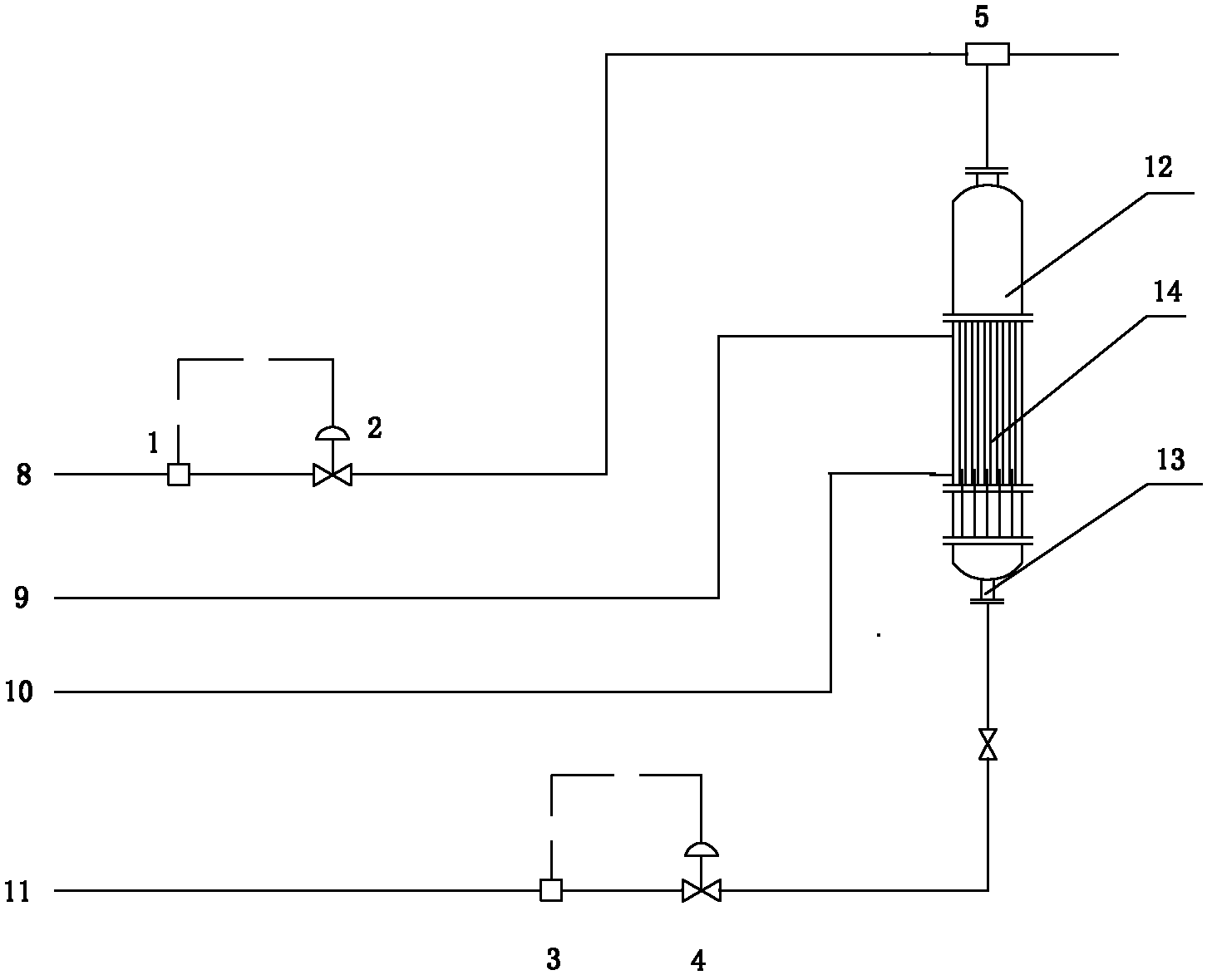

Method and device for efficiently producing polycrystalline silicon

InactiveCN101717088AImprove one-time yieldReduce production cyclePolycrystalline material growthSiliconInlet temperaturePolycrystalline silicon

The invention discloses a method for efficiently producing polycrystalline silicon. A raw material mixed gas consisting of trichlorosilane and hydrogen in a volume ratio of 1 to 2-15 is firstly delivered into a shell and tube heat exchanger to be heated, then delivered into a plate heat exchanger to exchange heat and delivered into a polycrystalline silicon reduction reactor to perform reaction, and the inlet temperature of the feed gas in the reduction reactor is kept between 200 and 500 DEG C; in the shell and tube heat exchanger, the feed gas exchanges heat with the tail gas produced in the polycrystalline silicon production process; in the plate heat exchanger, the feed gas exchanges heat with water vapor; and the reaction is controlled by adjusting the pressure, temperature and hydrogen flow till the reduction reactor is shut down. The method of the invention effectively improves the disposable yield of silicon, is favorable for reducing production cycle and energy consumption in the production process, is simple and feasible, greatly saves the production cost, and reduces the difficulty of treating the tail gas.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

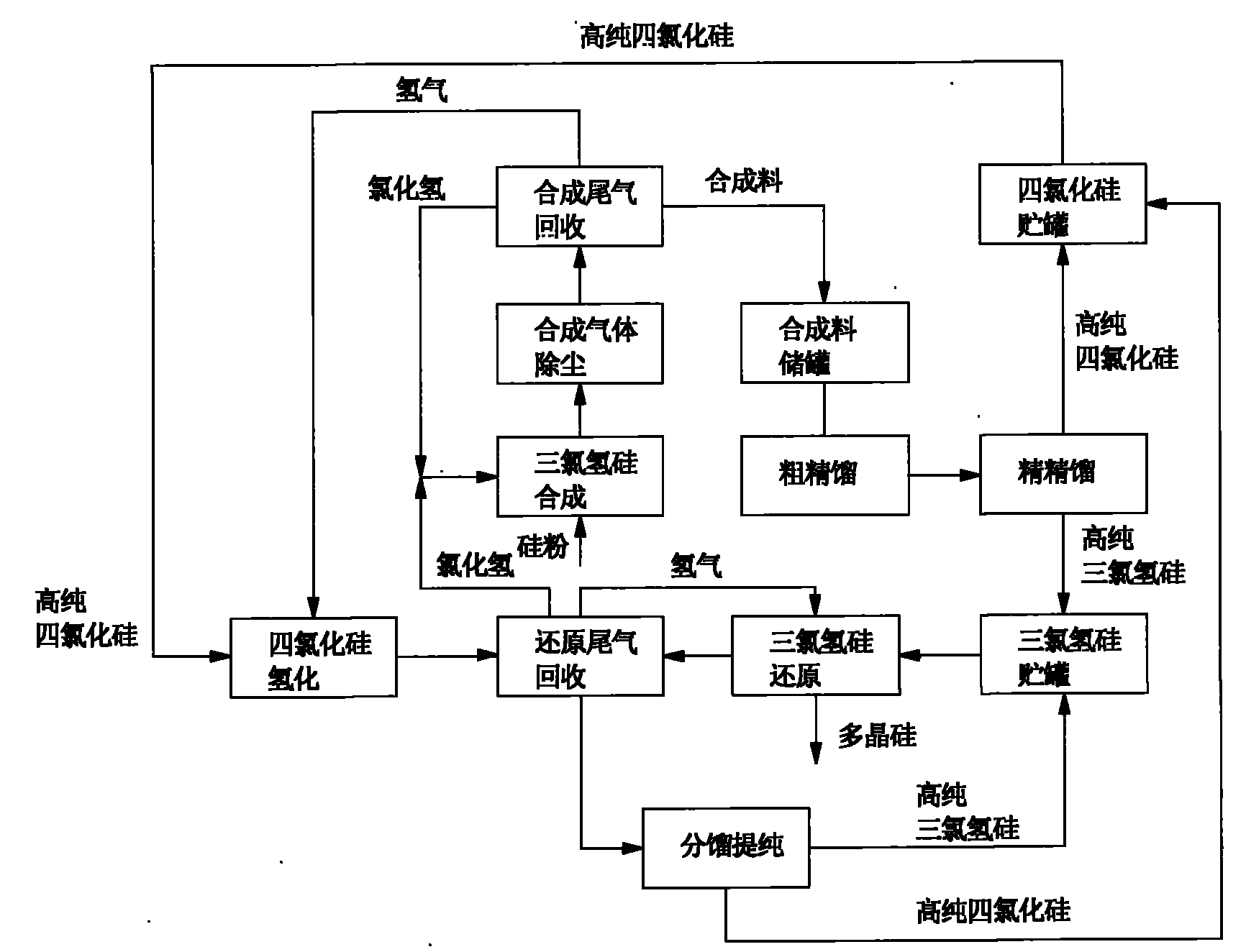

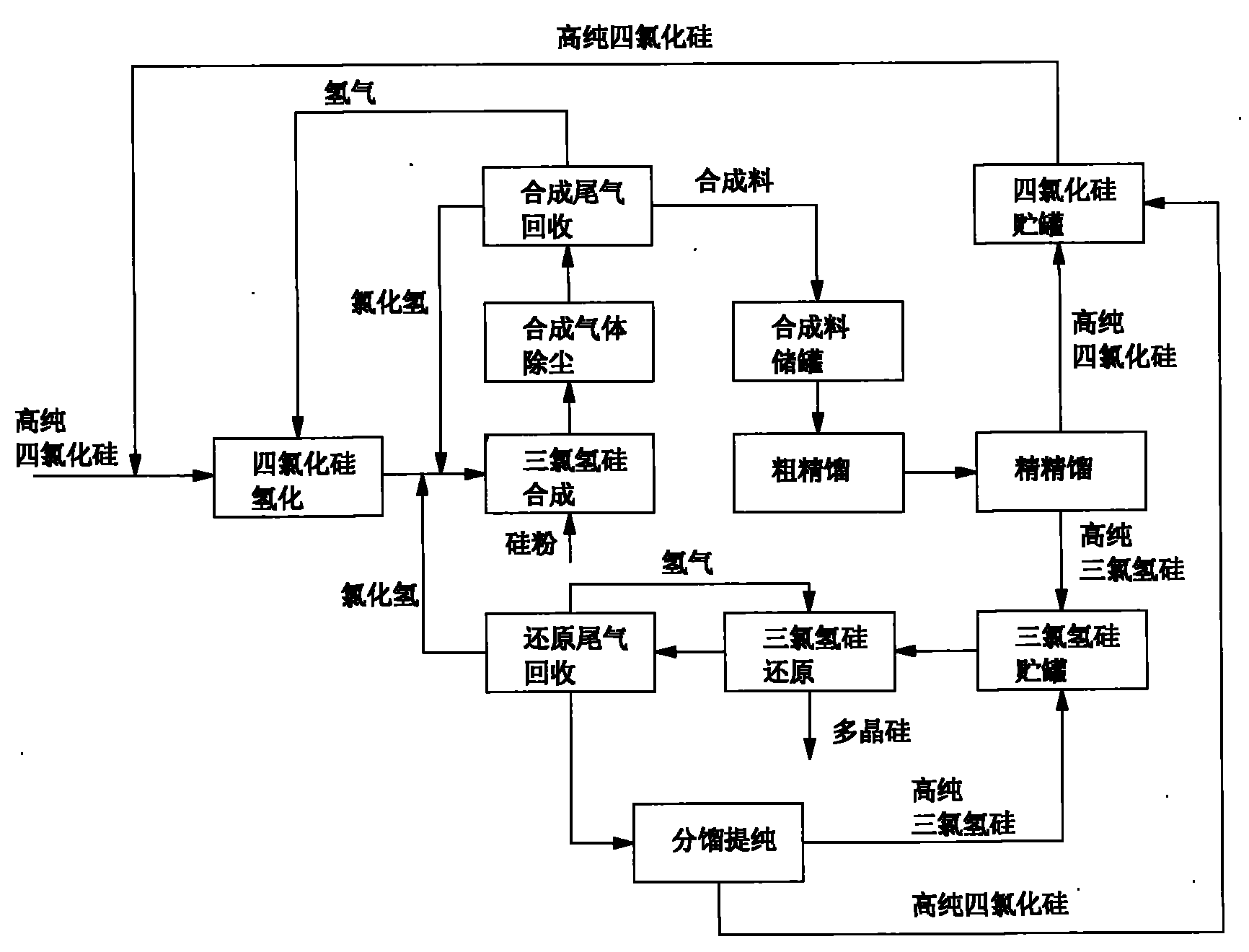

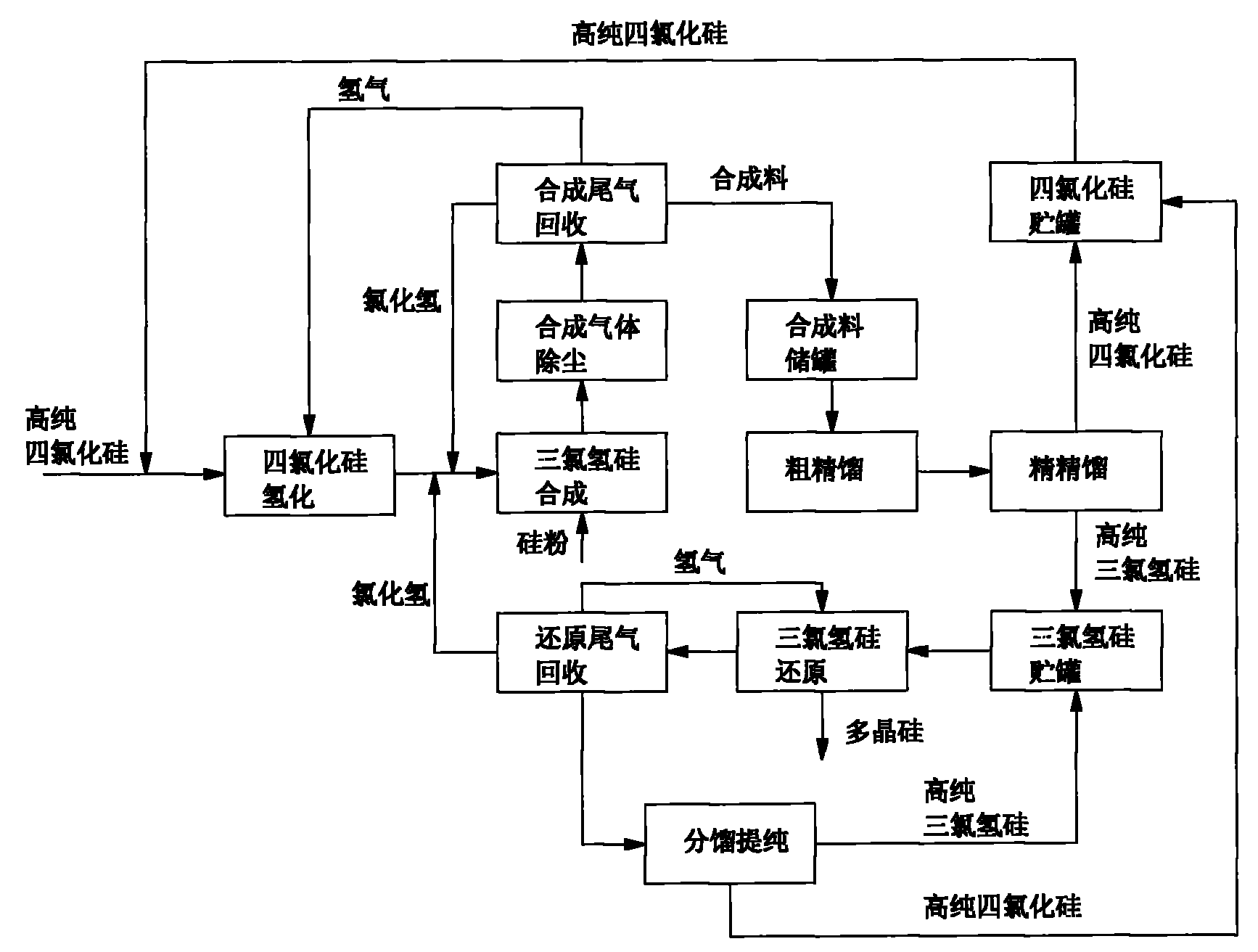

Polycrystalline silicon producing device and process

ActiveCN102030329AImprove conversion rateHigh puritySiliconHalogenated silanesClosed loopHydrogen chloride

The invention provides a polycrystalline silicon producing device, comprising a trichlorosilane synthesis furnace, a trichlorosilane reduction furnace, a silicon tetrachloride hydrogenation furnace, a trichlorosilane synthesis tail gas recycling device and a trichlorosilane reduction tail gas recycling device, wherein the tail gas outlet of the silicon tetrachloride hydrogenation furnace is connected with the feeding hole of the trichlorosilane synthesis furnace, and the air inlet of the trichlorosilane reduction tail gas recycling device is connected with the air outlet of the trichlorosilane reduction furnace. In the invention, the tail gas outlet of the silicon tetrachloride hydrogenation furnace is connected with the feeding hole of the trichlorosilane synthesis furnace, and tail gas produced by silicon tetrachloride hydrogenation directly enters the trichlorosilane synthesis furnace, thus achieving high yield of trichlorosilane and higher purity of polycrystalline product, avoiding discharge of massive impurity of chlorosilane, saving raw material and eliminating a film pressing machine, a liquid chlorine gasification device and a hydrogen chloride synthesis device; meanwhile, the whole production technological process is a material closed-loop circulation formed by silicon tetrachloride hydrogenation and trichlorosilane reduction, and no waste is discharged, thus being beneficial to environmental protection.

Owner:XINJIANG DAQO NEW ENERGY

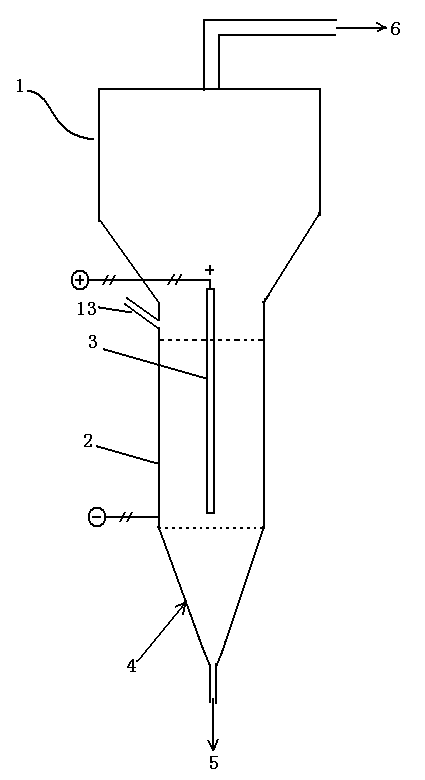

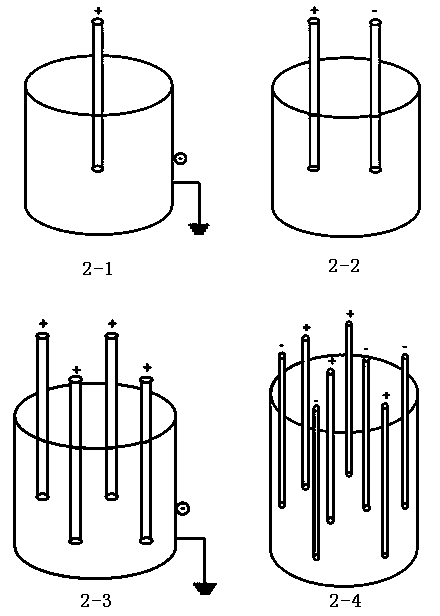

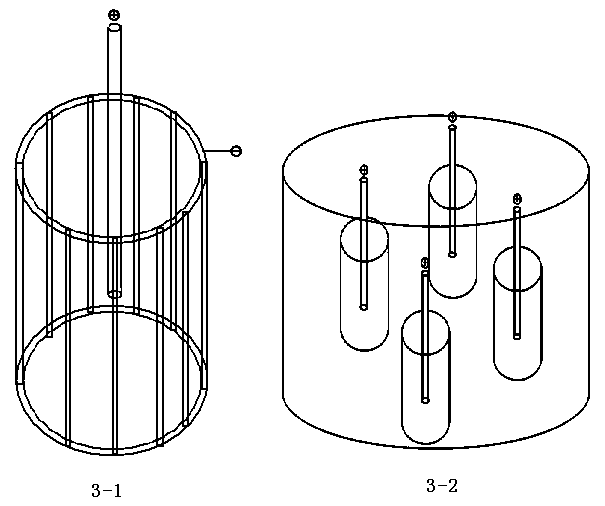

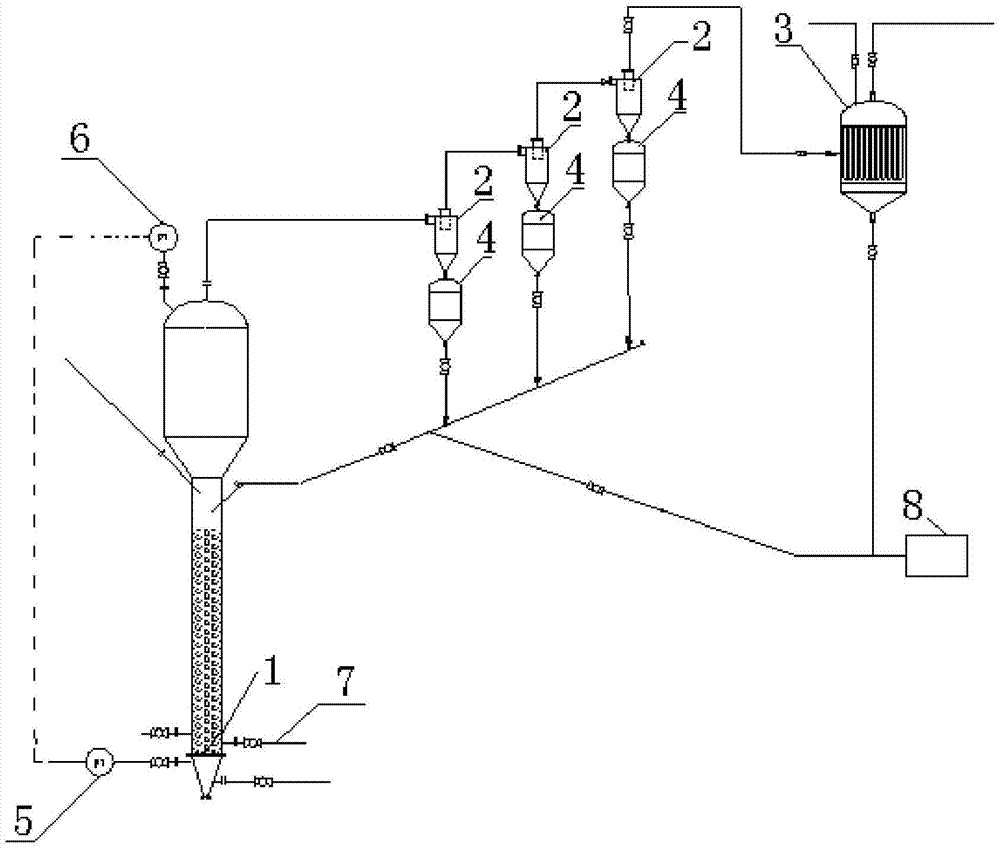

Fluidized bed reactor and method for preparing granular polysilicon and trichlorosilane by employing same

InactiveCN103990422AIncrease production capacitySiliconChemical/physical processesFluidized bedSilicon particle

The invention discloses a fluidized bed reactor and a method for preparing granular polysilicon and trichlorosilane by employing the same. By utilizing a positive electrode and a negative electrode in the fluidized bed reactor and enabling the current to flow through silicon particles, heat is supplied for the silicon particles in the reactor in a resistance heating manner. By employing the fluidized bed reactor, the purity of the products can be improved, the cost is reduced, industrialized application of large-diameter reactors is allowed, the output is improved, also the inner wall temperature of the reactor is reduced and further silicon deposition is reduced.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

Composite catalyst for preparing trichlorosilane through catalytic hydrogenation of silicon tetrachloride

ActiveCN103007995ASimple production processHigh catalytic efficiencyMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrogen atmosphere

The invention discloses composite catalyst for preparing trichlorosilane through catalytic hydrogenation of silicon tetrachloride. The active constituents of the catalyst comprise at least one second main group metallic element and at least one transitional metal element, or a compound of the second main group metallic element and that of the transitional metal element, and can be loaded on a carrier for use. The catalyst can be used for catalytic hydrogenation dehalogenation reaction of silicon tetrachloride in the atmosphere of 700 to 1000 DEG C and 1 to 30 bar hydrogen, has higher catalytic activity and favorable selectivity, and is low in cost, simple to prepare and stable in performance.

Owner:SICHUAN UNIV +1

Method for purifying and separating chlorosilane from polysilicon tail gas

ActiveCN103435044AReduce manufacturing costHalogenated silanesPhysical chemistrySilicon tetrachloride

The invention relates to a tail gas purifying technology in polysilicon production. A single rectifying method is traditionally adopted to separate impurities from trichlorosilane and needs a large apparatus and a high running cost. The invention provides a purifying method combining a polysilicon reduction reaction with a rectification, hydrolysis rectification and adsorption technology. The purifying method provided by the invention comprises the following steps: cooling tail gas, rectifying condensed trichlorosilane in a rectifying tower, allowing obtained trichlorosilane to enter a hydrolysis rectifying tower, allowing condensed partial trichlorosilane to enter an adsorption column, allowing purified trichlorosilane to enter a trichlorosilane separation tower, collecting a trichlorosilane product at the top of the trichlorosilane separation tower, allowing discharged silicon tetrachloride to enter the rectifying tower for purification, and collecting a silicon tetrachloride product at the bottom of the rectifying tower. The method provided by the invention has the advantages of apparatus simplification, low running cost, and reduction of the polysilicon production cost by 10%.

Owner:新疆新特新能材料检测中心有限公司

Process for producing trichlorosilane through inverse disporportionation of dichlorosilane

InactiveCN102923716AReduce processing costsIncrease profitHalogenated silanesChemical industryPtru catalyst

The invention discloses a process for producing trichlorosilane through inverse disporportionation of dichlorosilane, particularly to a process for producing the trichlorosilane through inverse the disporportionation of the dichlorosilane in a polycrystalline silicon production system, and belongs to the technical field of silicon chemical industry; according to the invention, in an inverse disporportionation process of the dichlorosilane, a mixed material of liquid dichlorosilane and liquid silicon tetrachloride is adopted; a fixed-bed reactor loaded with a catalyst is adopted for reaction; and mild reaction condition, low equipment investment and less energy consumption are obtained; inverse disporportionation can be carried out on side product dichlorosilane of the polycrystalline silicon production system so as to generate the trichlorosilane, so that the production cost and treatment cost of the dichlorosilane are reduced; as a gas-liquid separating unit and a rectifying raw material product separating system are also designed in the process, the traditional processing equipment of the production system can be sufficiently utilized, and the raw material utilization rate of the polycrystalline silicon production system is increased.

Owner:SICHUAN RENESOLA SILICON MATERIAL

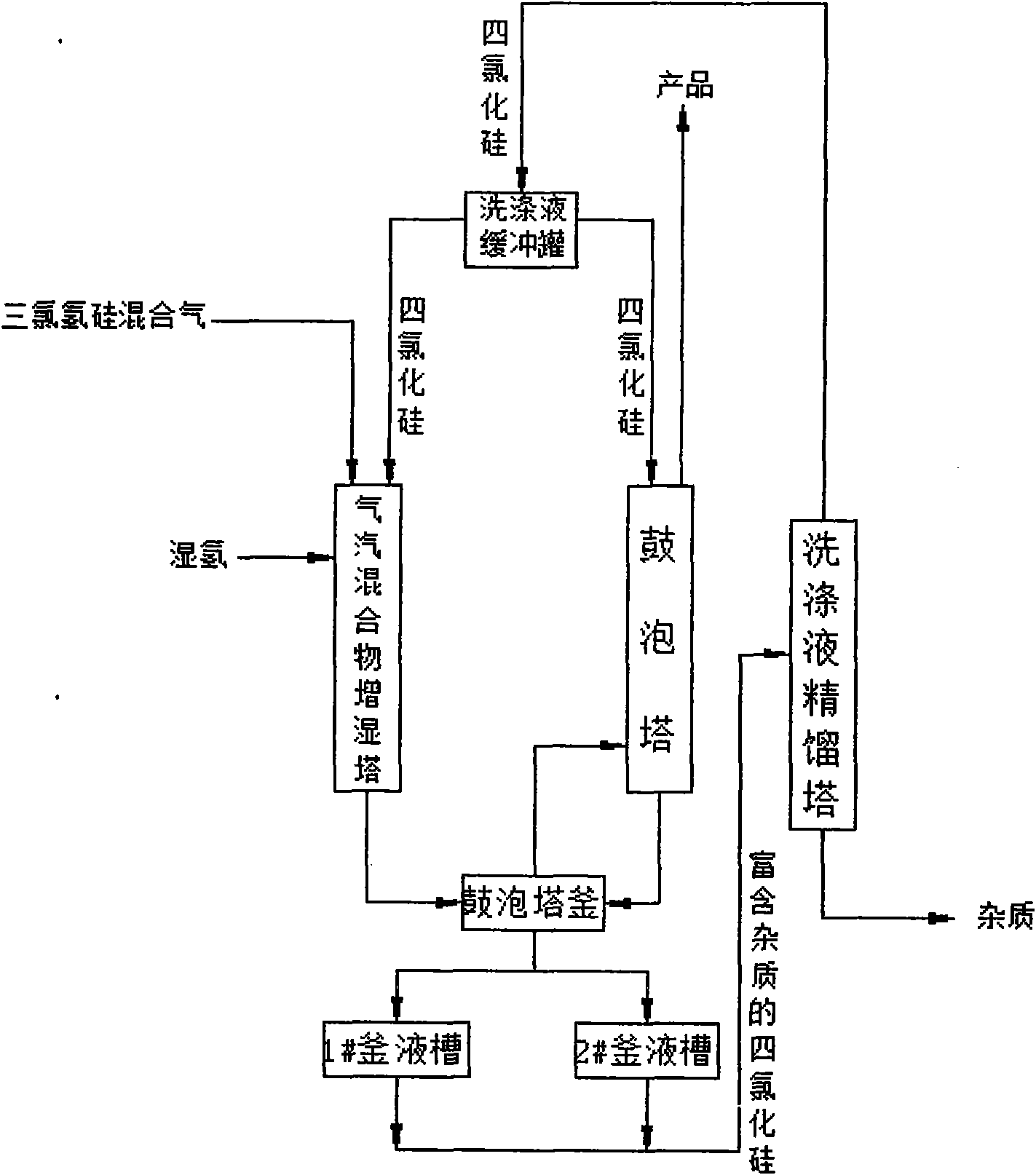

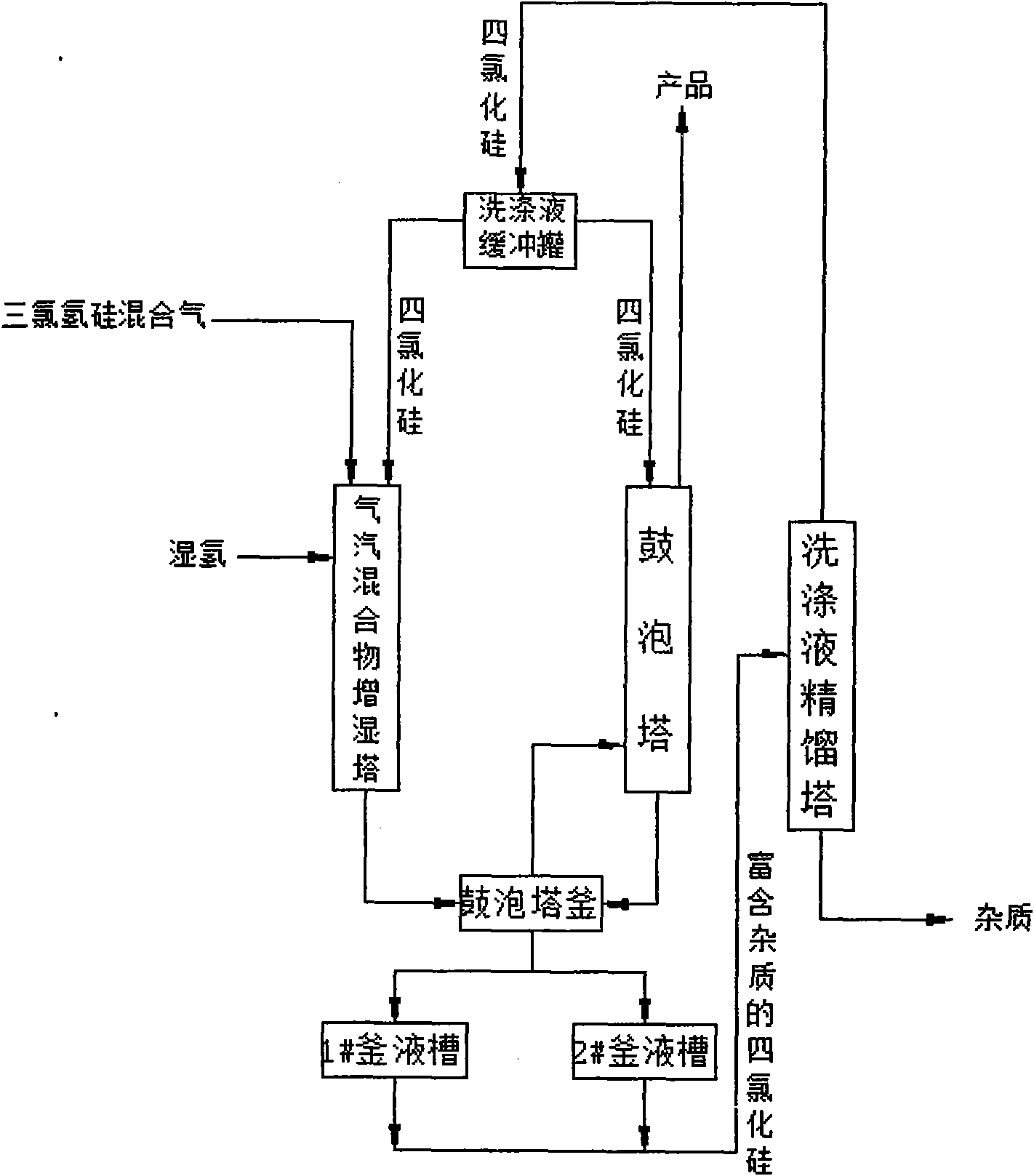

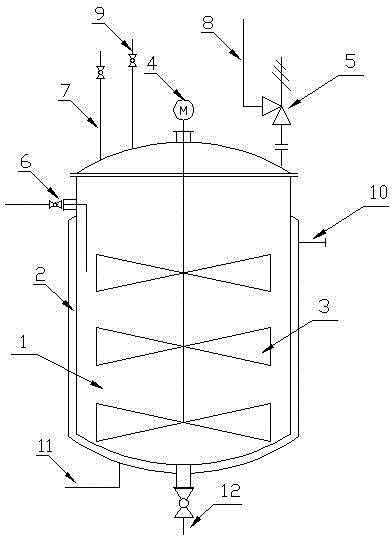

Method and device for removing impurities from trichlorosilane mixed gas

The invention discloses a method and a device for removing impurities from a trichlorosilane mixed gas. The method comprises the steps of: carrying out primary spraying on the trichlorosilane mixed gas in a gas and steam mixture humidifying tower by adopting silicon tetrachloride liquid, absorbing metal chloride and siliceous dust by silicon tetrachloride, introducing wet hydrogen in the trichlorosilane mixed gas to obtain SiO2 through reaction, absorbing boron and phosphorus in the trichlorosilane mixed gas through the SiO2; carrying out secondary spraying on the trichlorosilane mixed gas with the silicon tetrachloride liquid in a bubble column, and further removing the metal chloride to obtain a finished product of a trichlorosilane synthesis gas; and connecting the bubble column used for collecting the silicon tetrachloride obtained by spraying the silicon tetrachloride mixed gas for two times to a washing liquid distilling tower, distilling and purifying the silicon tetrachloride with impurities, and circularly spraying by using the silicon tetrachloride. The impurities are removed by adopting a wet method, the impurities in the trichlorosilane mixed gas can be fully removed to obtain high-quality refined trichlorosilane, the silicon tetrachloride can be circularly utilized, and the purposes of saving energy, reducing consumption and decreasing emission are achieved.

Owner:天威四川硅业有限责任公司

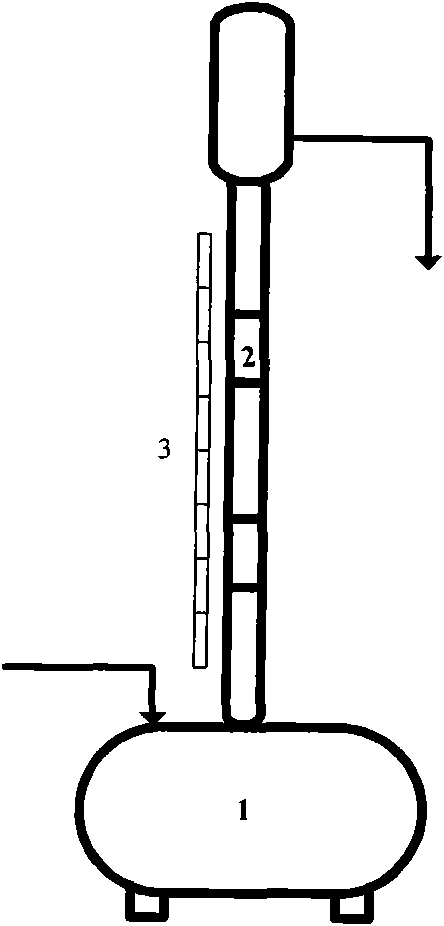

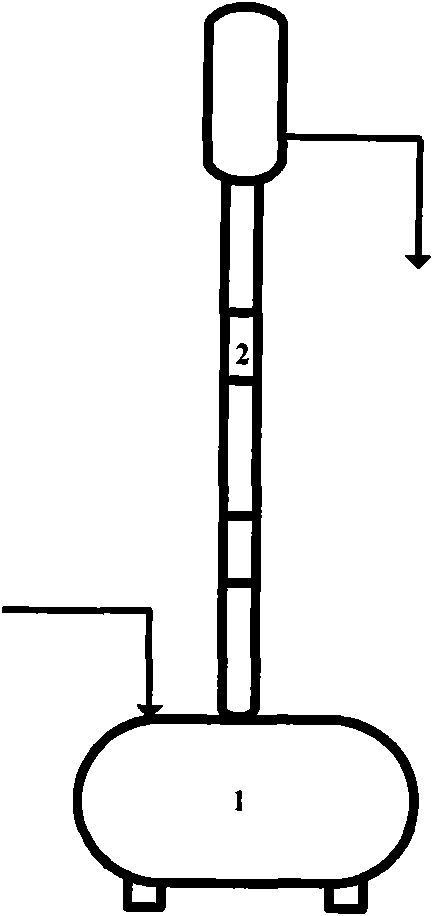

Reactive distillation method and equipment for preparing silane through direct disproportionation of trichlorosilane

ActiveCN103241743AOvercome the limitation of low conversion rateAvoid separation cycle reactionsChemical industryHalogenated silanesGas phaseSilanes

The invention relates to a reactive distillation method and equipment for preparing silane through direct disproportionation of trichlorosilane. The reactive distillation method comprises the following steps of: introducing refined trichlorosilane with the purity up to over 9N to a one-step disproportionation reaction distillation tower to prepare the silane; extracting a reaction product from the top of the disproportionation reaction distillation tower in a gas phase way, entering a silane tower by utilizing differential pressure, obtaining a chlorosilane mixture at the bottom of the tower, and entering a silicon tetrachloride tower; obtaining a high-purity liquid-phase silane product at the top of the silane tower, obtaining unreacted chlorosilane at the bottom of the tower, and returning the unreacted chlorosilane to the disproportionation reaction distillation tower; and obtaining unreacted chlorosilane at the top of the silicon tetrachloride tower, returning the unreacted chlorosilane to the disproportionation reaction distillation tower, and obtaining a silicon tetrachloride product at the bottom of the tower. Light and heavy impurities in the refined trichlorosilane raw material with the purity lower than 9N are removed after the trichlorosilane passes through a partition plate rectification tower so as to obtain trichlorosilane with the purity up to over 9N. The one-step disproportionation reaction is realized in one reaction distillation tower, the equipment is simplified, meanwhile, a great number of circular reactions for material separation are avoided, the processes are shortened, the energy is saved, and the consumption is reduced. The purity of a silane product is higher.

Owner:黄国强

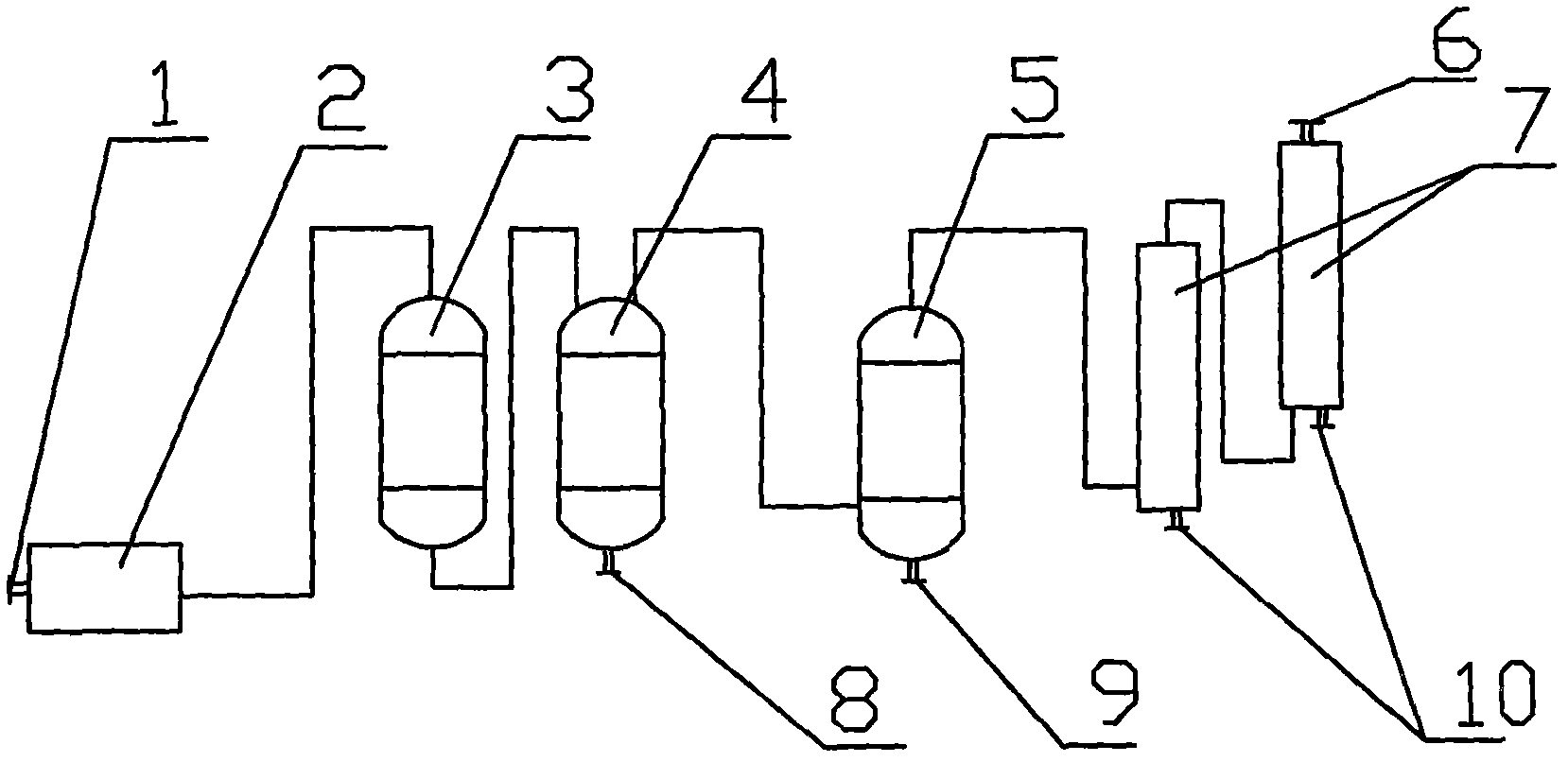

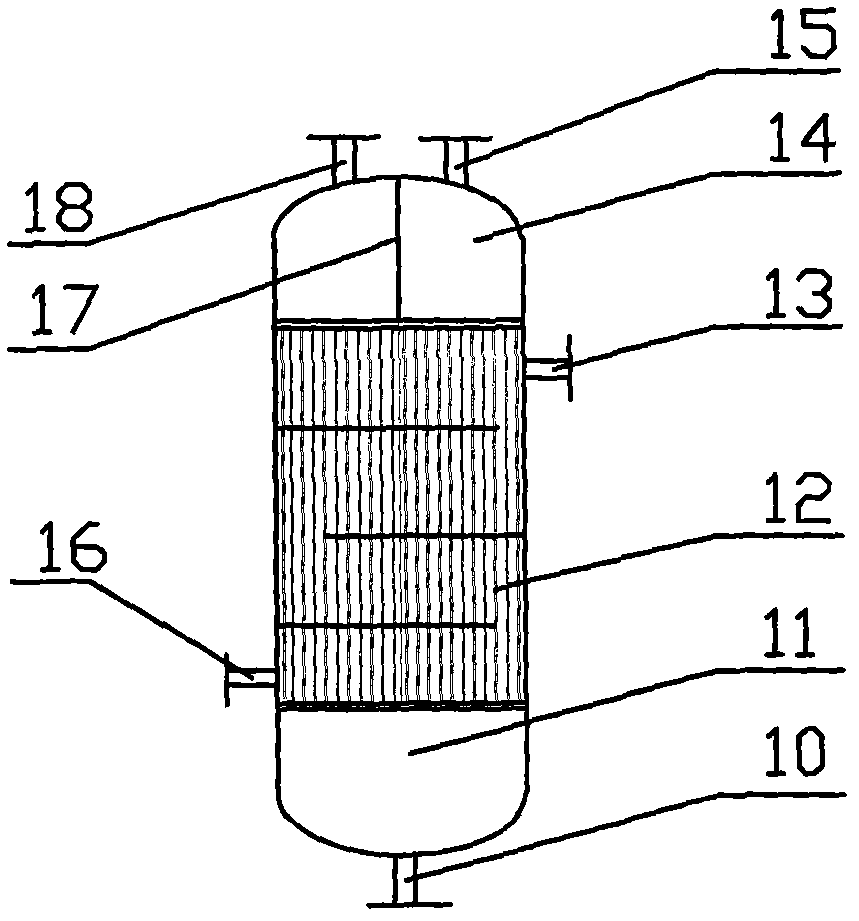

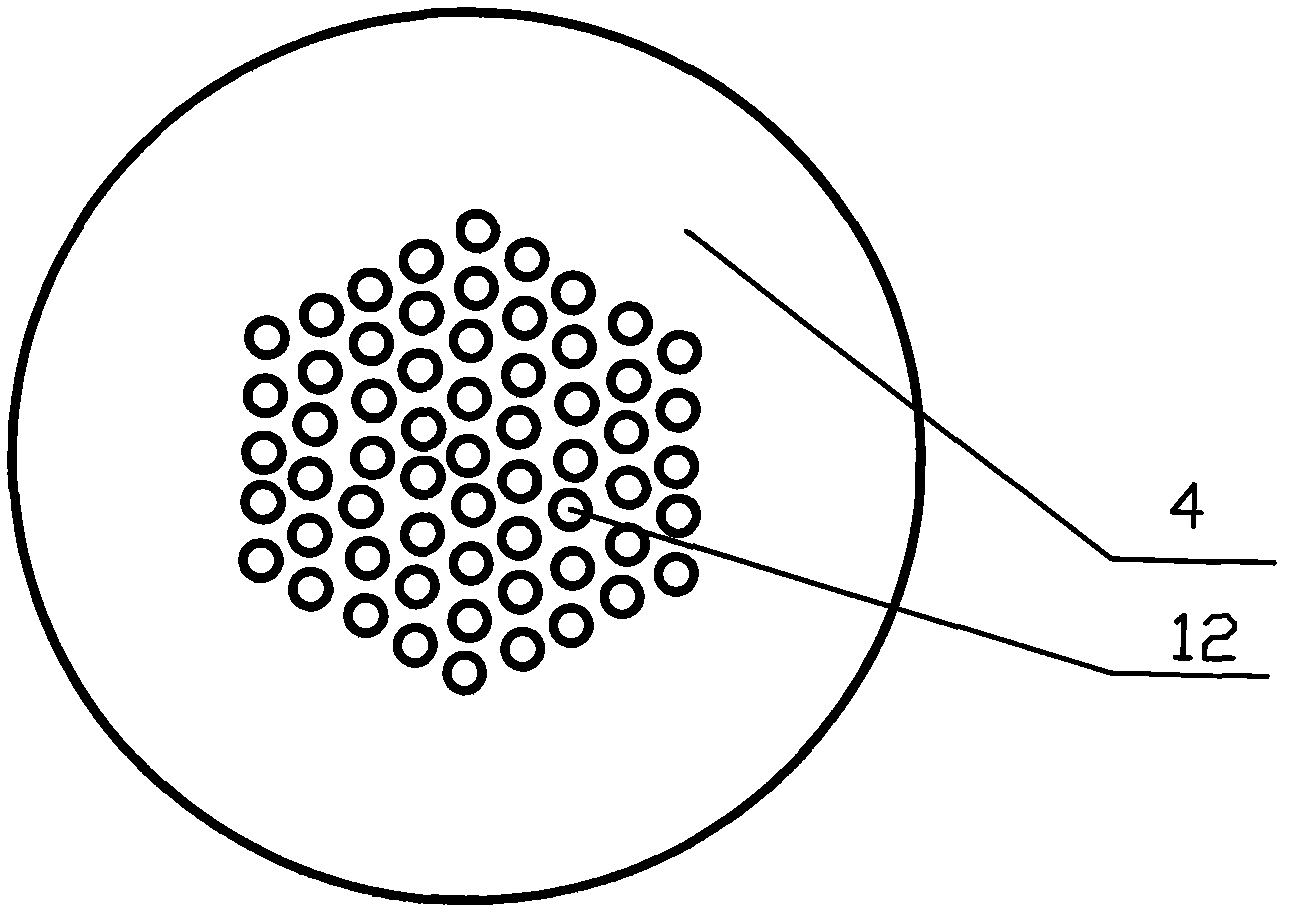

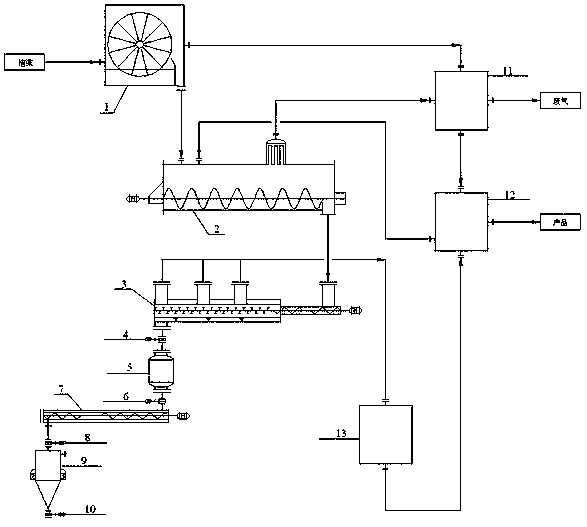

Process and device for treating tail gas during producing trichlorosilane

InactiveCN102101000APromote environmental protectionChlorine/hydrogen-chloride purificationDispersed particle separationExhaust gasHydrogen chloride

The invention relates to a process and device for treating tail gas during producing trichlorosilane. The process provided by the invention comprises: the tail gas generated from a trichlorosilane synthesizing workshop section and a trichlorosilane fractionating workshop section is compressed by a diaphragm compressor in a pressuring way, then condensed by a rear water condenser, deeply condensed by a rear deep condenser, and finally absorbed by a circulating absorption tower to recover the chlorosilane; and the hydrogen chloride in the tail gas which is absorbed by the circulating absorption tower is absorbed by a secondary falling film absorption tower to be made into 30% hydrochloric acid, and the tail gas which is absorbed by the falling film absorption tower is directly discharged to the air after being checked out. The device provided by the invention consists of the diaphragm compressor, the rear water condenser, the rear deep condenser, the circulating absorption tower and the falling film absorption tower which are connected with the one another in series by pipelines, wherein the diaphragm compressor is provided with a tail gas inlet, and the falling film absorption tower is provided with an outlet and an emptying port. According to the invention, the 99.5% of chlorosilane and hydrogen chloride can be recovered; the great mass of the chlorosilane and hydrogen in the tail gas not only can be recovered, but also can be reused, so that the process and device provided by the invention are favorable for environmental conservation.

Owner:湖北江盐天祥化工有限公司

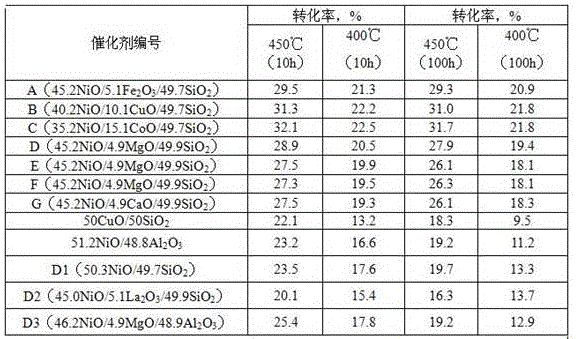

Catalyst, preparation method and application thereof

InactiveCN105944728AShorten the purification processEasily brokenHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsSolventSilicon dioxide

The invention discloses a catalyst and a preparation method thereof. The method comprises: contacting a soluble nickel salt, a soluble salt compound of metal M, a silicon source able to provide silica with a precipitant able to precipitate nickel and / or metal M ions in a solvent, filtering the contact product, and drying and roasting the obtained solid in order, wherein the M is selected from one or more of I B, II B, II A and group VIII metals except Ni. The catalyst prepared according to the method provided by the invention can be applied in preparation of trichlorosilane by hydrogenation of silicon tetrachloride. Compared with conventional aluminum-based catalysts, the catalyst prepared by the method provided by the invention has the advantages that: in the reaction atmosphere of preparation of trichlorosilane by hydrogenation of silicon tetrachloride, the SiO2 carrier is stable, the catalyst skeleton is not easily damaged as the carriers in traditional hydrogenation catalysts, therefore the service life can be longer, and compared with nickel salt and copper salt catalysts commonly used in the prior art, the activity is enhanced.

Owner:HENAN NORMAL UNIV

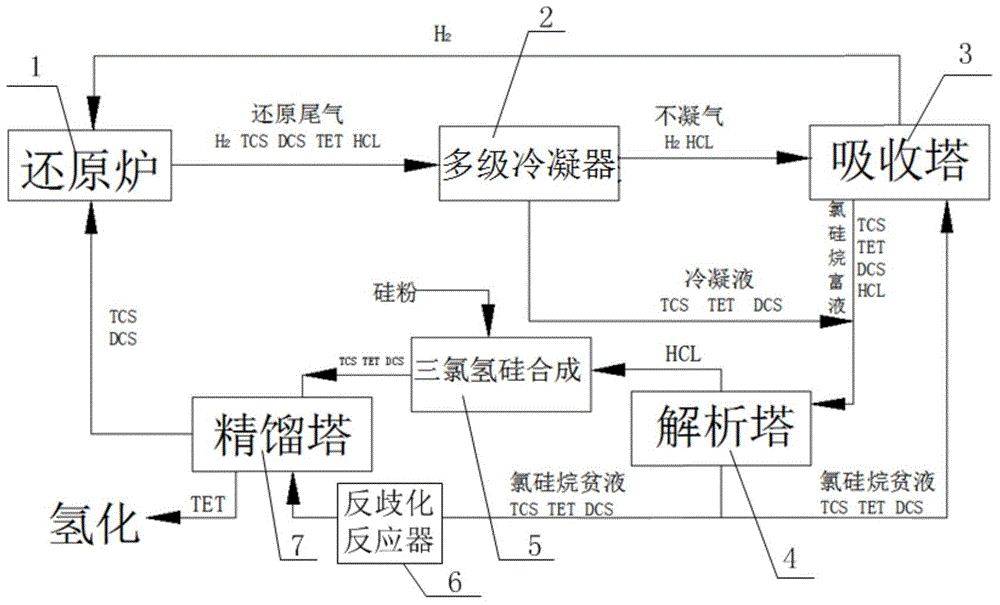

Polycrystalline silicon production method and equipment based on improved Siemens method

ActiveCN104556042AReduce manufacturing costThe mass percentage is reducedSilicon compoundsDichlorosilaneTower

The invention discloses a polycrystalline silicon production method and polycrystalline silicon production equipment based on improved Siemens method, and belongs to the technical field of polycrystalline silicon production. The problems that the purity of trichlorosilane participating in a reduction reaction is low and first-time conversion rate of trichlorosilane is influenced to cause high production cost of the polycrystalline silicon are solved. According to the technical scheme, the polycrystalline silicon production method comprises the following steps: step 1, performing reduction and deposition on trichlorosilane to acquire polycrystalline silicon and exhausting tail gas; step 2, performing multilevel condensation on the tail gas to acquire non-condensable gas and condensate liquid, introducing the non-condensable gas into an absorption tower, absorbing HCL in the non-condensable gas and enabling a chlorosilane pregnant solution to flow out; after mixing the condensate liquid with the chlorosilane pregnant solution, enabling the condensate liquid to flow into an analyzing tower; step 3, performing a disproportionation reaction on at least a portion of chlorosilane barren liquid flowing out of the analyzing tower, so that the mass percentage content of dichlorosilane in the chlorosilane barren liquid is reduced; step 4, enabling the chlorosilane barren liquid after reaction to flow into a rectifying tower and pouring a product acquired in the rectifying tower into a reduction furnace.

Owner:XINJIANG DAQO NEW ENERGY

Method for preparing silicon tetrachloride for optical fiber

InactiveCN102107875AReduce hydrogen impuritiesLow content of metal impuritiesSilicon halogen compoundsIndustrial scaleMaterials science

The invention provides a method for preparing silicon tetrachloride for optical fiber. The method comprises the following steps of: introducing chloride under the protective atmosphere of inactive gas or inert gas and under the condition of illumination, so that trichlorosilane is subjected to a photochemical reaction in a rectifying tower, wherein high-boiling-point silicon tetrachloride generated in the production process of polycrystalline silicon serves as a raw material; and controlling the tower kettle temperature and the tower top temperature and taking materials by selecting proper reflux ratio to obtain an intermediate product; further rectifying and purifying the intermediate product to obtain high-purity silicon tetrachloride, wherein infrared transmissivity of hydrogen-containing impurities meets the requirement of the silicon tetrachloride for the optical fiber on impurity transmissivity; and the metal ion content meets the metal content standard of the silicon tetrachloride for the optical fiber. The method has the advantages that: the trichlorosilane with the boiling point close to that of the silicon tetrachloride is removed effectively; the hydrogen-containing impurity content and the metal impurity content of the silicon tetrachloride are reduced; the quality of the silicon tetrachloride purified and prepared by the process completely meets the requirement of optical fiber products; the reaction condition and the completeness are easy to control; other impurities are not introduced; and the method is implemented in an industrial scale and in an effective and economic mode.

Owner:BEIJING GUOJING INFRARED OPTICAL TECH

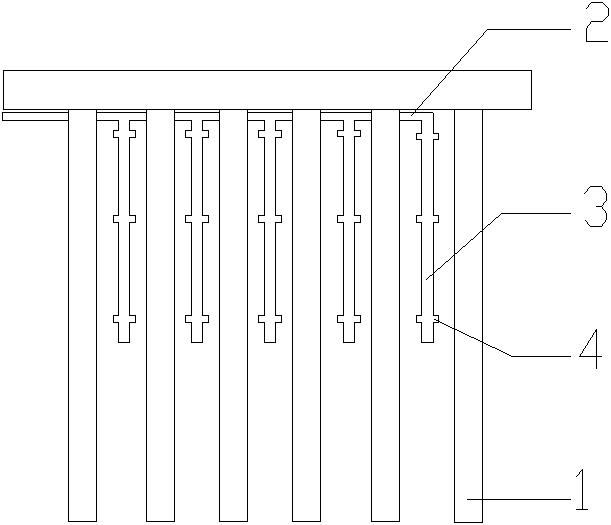

Method for processing tail gas and dust generated by producing trichlorosilane

ActiveCN102029093ASatisfy the conditions required for continuous productionRealize continuous operationDispersed particle filtrationNitrogenEngineering

The invention relates to a method for producing trichlorosilane and equipment thereof, in particular to a processing method of dust generated in the producing process of trichlorosilane and equipment thereof. The mixture of the tail gas and the dust in the producing process of the trichlorosilane is processed through a filtering device, the intercepted dust is then processed through a bag filter in two steps, at least one cloth-bag blowing pipe for blowing out nitrogen is arranged in the bag filter for processing the dust, and the cloth-bag blowing pipe comprises a main pipe, a branch pipe and at least one nozzle, wherein the main pipe is arranged at the bottom or the top of the filter, a branch pipe is installed on the main pipe and is parallel between filtering bags and the nozzle is arranged on the branch pipe; and at least one dust blowing pipe is arranged at the dust inlet of the bag filter, the dust blowing pipe is used for blowing out the nitrogen, and the dust is deposited at the bottom of the bag filter after being blown dispersedly. The processing method of the tail gas and the dust of the invention can realize continuous operation, saves the usage amount of the nitrogen, reduces the discharge of pollutants, and can be used for producing byproducts containing ammonium chloride.

Owner:江西宏柏新材料股份有限公司

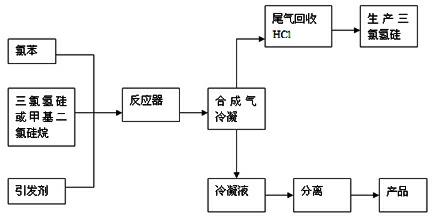

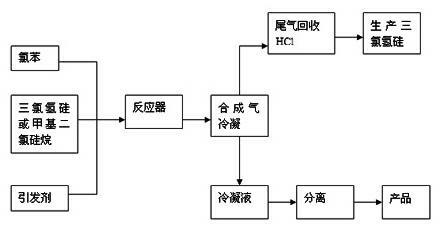

Thermal condensation production method for phenyl chlorosilane

InactiveCN102443021ALow reaction temperatureReduce energy consumptionGroup 4/14 element organic compoundsChlorobenzenePeroxydisulfate

The invention discloses a thermal condensation production method for a phenyl chlorosilane; with chlorobenzene and trichlorosilane as raw materials or with chlorobenzene and methyl dichloresilane as raw materials, in the action of an initiator, the raw materials are reacted in a reactor to produce synthetic phenyl chlorosilane gas under the conditions of controlling the temperature to be 300-600 DEG C and the pressure to be 0.2-0.8 MPa; the molar ratio of the chlorobenzene and the trichlorosilane in the raw materials is 0.7: 1 to 1:1; and the molar ratio of the chlorobenzene and the methyl dichloresilane in the raw materials is 0.7:1 to 1:1. The initiator is one of trichloromethane, potassium peroxydisulfate, azodiisobutyronitrile and dibenzoyl peroxide; and the dosage of the initiator is 0.1-2% wt of the total amount of the materials. The thermal condensation production method for the phenyl chlorosilane disclosed by the invention has simple equipment and is high in reaction efficiency, low in cost and easy to form industrial production.

Owner:ZHEJIANG KAIHUA SYNTHETIC MATERIAL

Catalyst for transforming silicon tetrachloride into trichlorosilane through hydrodechlorination and preparation method of catalyst

InactiveCN103754883AHigh catalytic efficiencySmall particlesMetal/metal-oxides/metal-hydroxide catalystsHalogenated silanesMagnetic separationChemistry

The invention discloses a catalyst for transforming silicon tetrachloride into trichlorosilane through hydrodechlorination and a preparation method of the catalyst. Nickel, copper and palladium are taken as major active ingredients of the hydrodechlorination catalyst, nickel particles, copper particles and palladium particles are slowly adsorbed, reduced and deposited in surface and pore of activated carbon layer by layer through step-by-step controlled reduction and in-situ deposition, and the three metallic particles are uniformly distributed and mutually cooperated, so as to effectively improve a catalytic efficiency of transforming silicon tetrachloride into trichlorosilane through hydrodechlorination. The catalyst preparation method disclosed by the invention has the characteristics of simple process, moderate condition and relatively low investment; the prepared catalyst has certain magnetism, which is favorable for magnetic separation and recovery after using the catalyst. According to the catalyst, mass percentage of loading three metals on an activated carbon load is 15-30%, and specific surface area is 300-700m<2> / g.

Owner:HENAN UNIV OF SCI & TECH

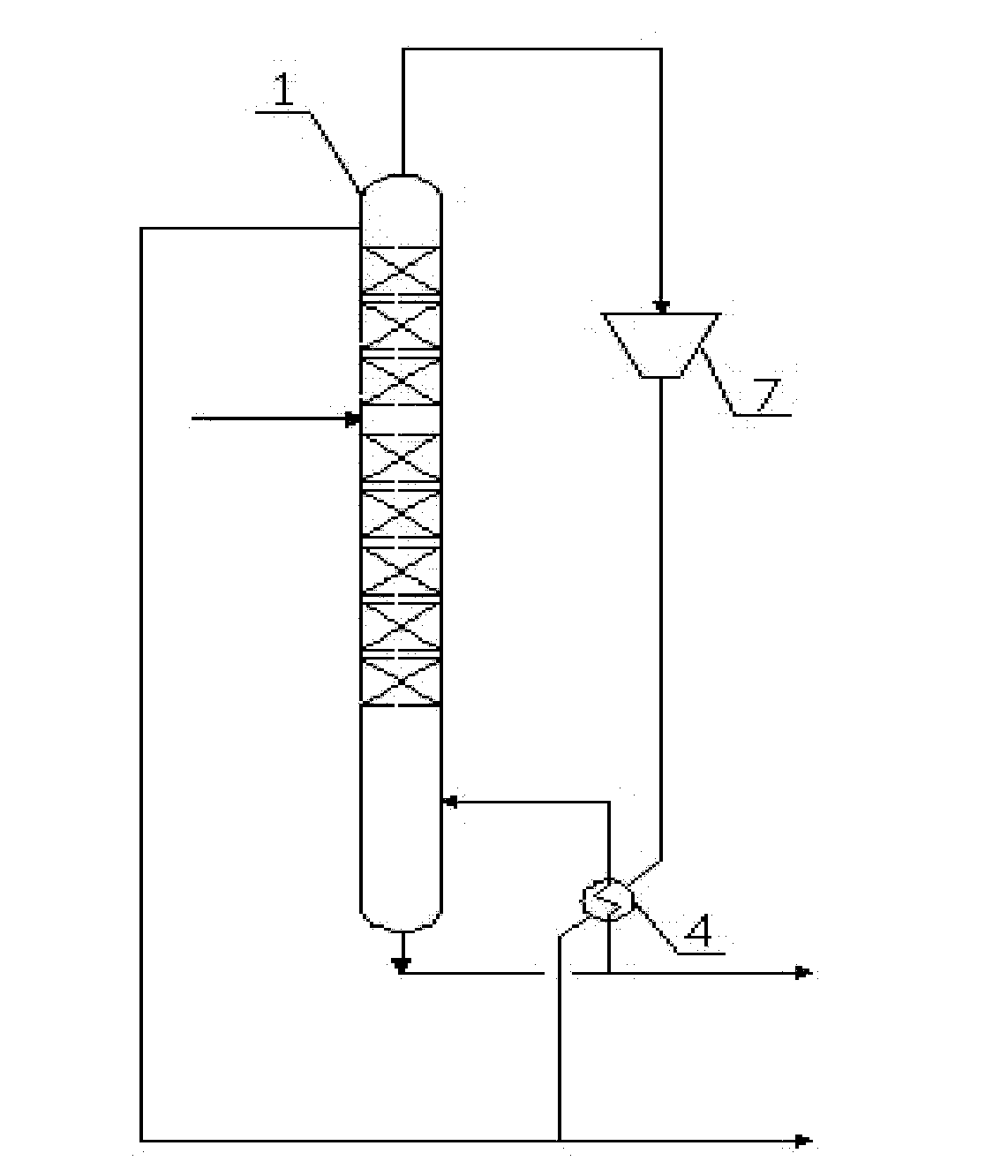

Trichlorosilane vaporizing process

The invention relates to a polycrystalline silicon production process, in particular to a trichlorosilane vaporizing process, belonging to the technical filed of production of polycrystalline silicon. The trichlorosilane vaporizing process comprises the following steps of: (1) rectifying to obtain high-purity trichlorosilane liquid, metering and feeding into an evaporator for evaporating; and (2)mixing the trichlorosilane gas obtained through evaporation with metered hydrogen in a gas mixer to obtain a mixed gas. In the trichlorosilane vaporizing process, the trichlorosilane gas is mixed with the hydrogen, so that the uniformly mixed gas with a stable mixture ratio can be obtained; and raw materials are mixed more uniformly, uniform growth of polycrystalline silicon rods in a reduction furnace is promoted, and grown polycrystalline silicon products have uniform crystal grains and better appearance quality.

Owner:SICHUAN XINGUANG SILICON TECH

Waste residue comprehensive utilization method for trichlorosilane leaching system

ActiveCN104445281ATake advantage ofReduce pollutionSolid waste managementSolid waste disposalFiltrationTap water

The invention discloses a waste residue comprehensive utilization method for a trichlorosilane leaching system. The waste residue comprehensive utilization method comprises the following steps: filter pressing a leaching waste residue mixed solution formed by the leaching system by using a filter press to obtain leaching waste residue; putting the leaching waste residue into a drum mixer, adding an appropriate amount of tap water, and stirring to obtain a slurry; discharging the slurry to a dissolving tank by utilizing a high potential difference, adding the appropriate amount of the tap water, mechanically stirring to dissolve for 1.5-4 hours, and obtaining a feed liquid containing sodium chloride; filter pressing the feed liquid to obtain insoluble residue and filtrate, storing the insoluble residue for later use, performing secondary refined filtration on the obtained filtrate, injecting a refined filtration mother liquid into a double-effect evaporator through a centrifugal pump to evaporate and crystallize, and obtaining a finished product, sodium chloride with the purity of more than 99%. According to the waste residue comprehensive utilization method for the trichlorosilane leaching system, soluble salt and insoluble salt are effectively separated, and a purpose of recycling leaching waste residue in a classifying manner is achieved; the environment pollution and the wasting of resources are reduced, and the economic benefits are increased.

Owner:河南尚宇新能源股份有限公司

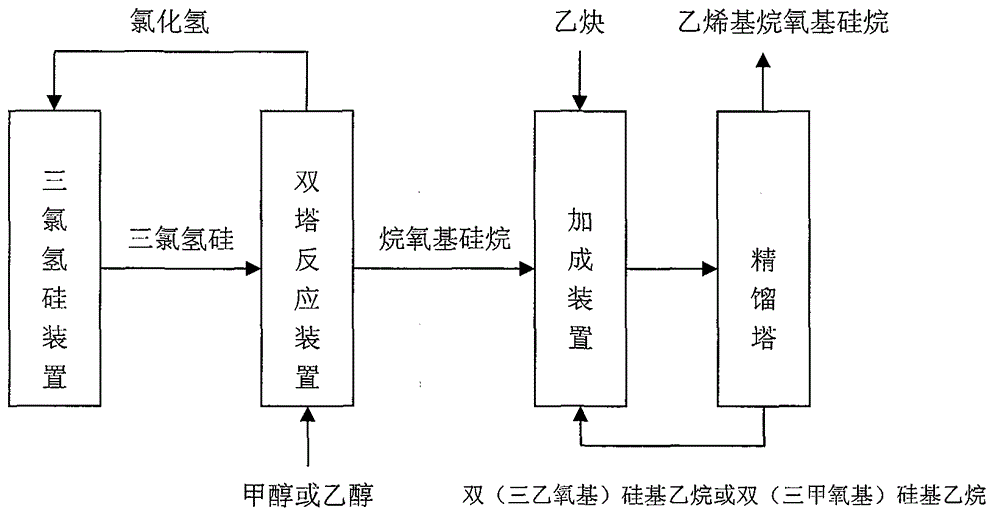

New vinyl alkoxy silane preparation process

ActiveCN105367598AAvoid introducingIncrease the rate of addition reactionGroup 4/14 element organic compoundsPolymer scienceSilanes

The present invention discloses a new vinyl alkoxy silane preparation process, which is characterized in that hydrogen chloride produced during a preparation process is adopted as a reactant to synthesize an initial raw material trichlorosilane, the hydrogen chloride is recycled, and the byproduct bis(trialkoxy)silyl ethane is adopted as a reaction solvent during a hydrogen silicon addition process, such that the byproduct emission is reduced, the new impurity introduction is avoided, and the product purity is improved. According to the present invention, the new process has characteristics of stable production, simple preparation process, and mild reaction conditions, and the yield of the product vinyl alkoxy silane is high, and the product purity is more than 99%.

Owner:ZHEJIANG KAIHUA SYNTHETIC MATERIAL +1

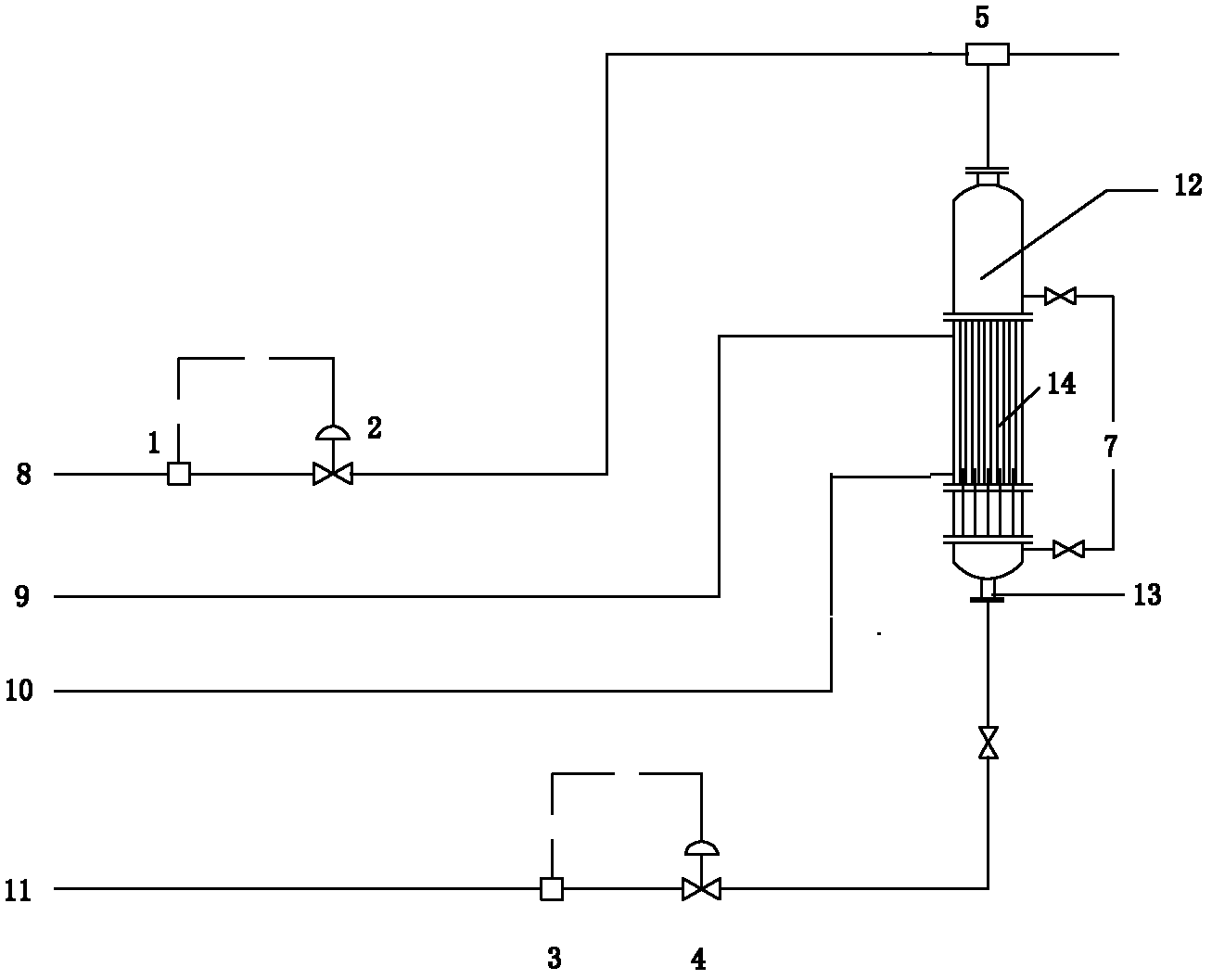

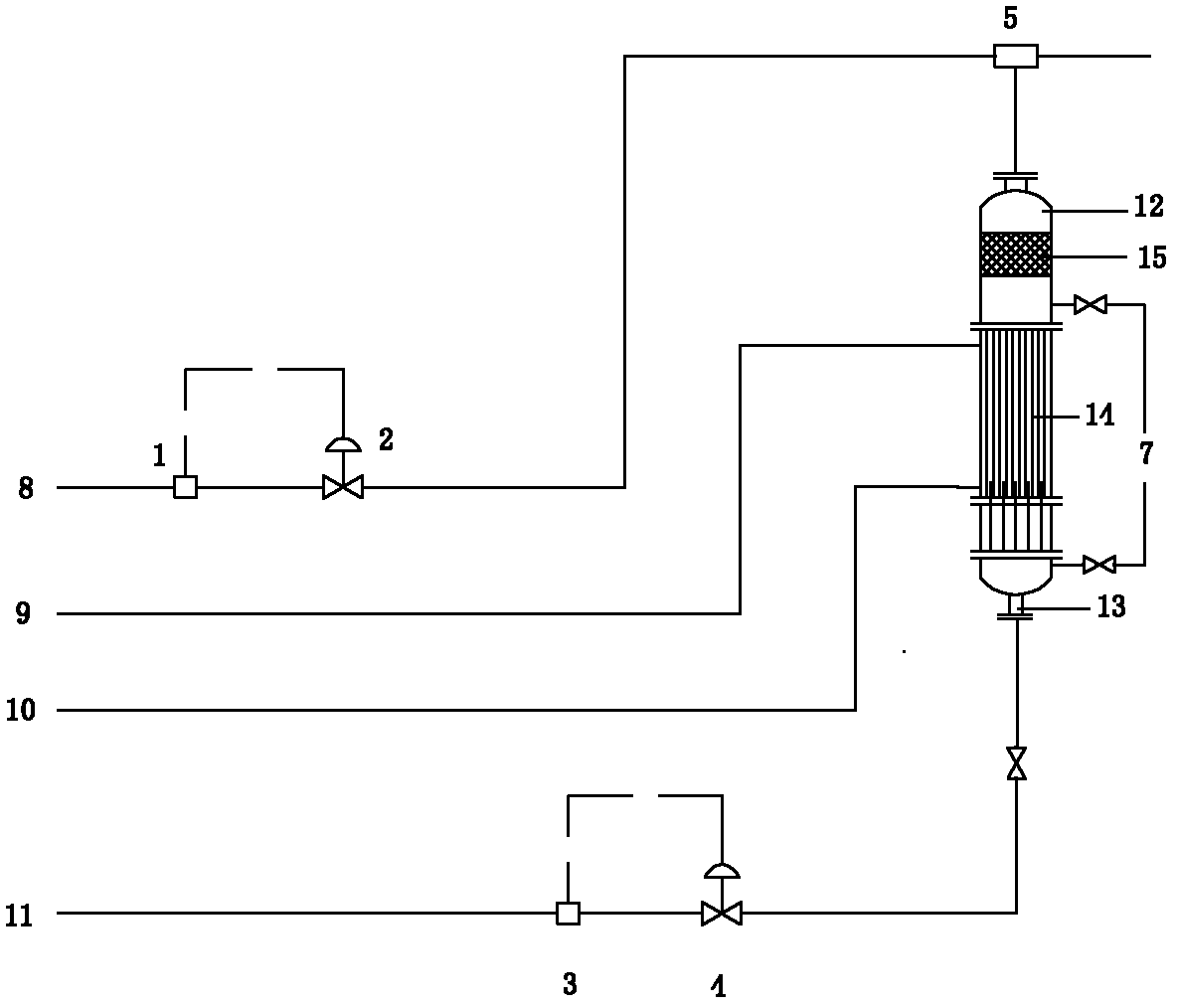

Method and equipment for intermittently recycling waste liquid of chlorosilane during polycrystalline silicon production

ActiveCN102910633AImprove handling of difficult problemsReduce wasteHalogenated silanesProcess engineeringEnvironmental engineering

The invention discloses a method for intermittently recycling chlorosilane in discharged waste liquid in a washing tower during polycrystalline silicon production, and the method the following steps of: intermittently charging a chlorosilane waste liquid produced in polycrystalline silicon production into an evaporation device at different places, evaporating trichlorosilane and silicon tetrachloride with lower boiling point into a gas state when the temperature of the evaporation device is controlled at 120-180DEG C and the pressure of the evaporation device is controlled at 0.1-0.6MPa, and charging the gaseous trichlorosilane and silicon tetrachloride into a rectifying tower so as to be purified and recycled. The invention further provides the evaporation device used in the method. The invention has the beneficial effects that the method is simple in process, the process condition is easy to realize, and the method is convenient to operate; and the treatment difficulty of the chlorosilane waste liquid during polycrystalline silicon production in the process of production can be improved, the discharge quantity of exhaust liquor can be mainly reduced, the waste of the chlorosilane can be reduced, the treatment load of an alkali liquor pond can be reduced, the environment pollution problem can be remitted, the labor quantity can be reduced, the production cost can be reduced, the complete recycle of the chlorosilane can be realized, and the phenomenon of equipment blockage can be avoided.

Owner:XINTE ENERGY

Anhydrous treatment process for polycrystalline silicon slurry

PendingCN110950342AEasy to recycleImprove economyHalogenated silanesPhysical chemistrySilicon tetrachloride

The invention relates to an anhydrous treatment process for polycrystalline silicon slurry. The process comprises the following steps of (1) carrying out solid-liquid-gas separation on upstream polycrystalline silicon slurry to obtain a liquid, gas A and a solid A, treating the liquid and the gas A, and collecting to obtain a liquid A; (2) heating and stirring the solid A by steam to obtain a dried solid product and silicon tetrachloride and part of trichlorosilane which exist in a gas manner, treating the silicon tetrachloride and part of trichlorosilane existing in a gas form, and collectingto obtain a liquid B; (3) heating the dried solid product through a pyrolyzing furnace to obtain solid wastes and high-boiling residues in a gaseous form, and carrying out catalytic cracking on the high-boiling residues in the gaseous form to obtain gas B and a liquid C; (4) allowing the solid wastes to pass through a gas locking tank, a cooling screw and a solid bin in sequence and discharging the solid wastes to a packaging and delivery unit, and (5) separating the liquid A, the liquid B, the liquid C and the gas B to obtain silicon tetrachloride and trichlorosilane products, residual high-boiling residues and part of solid B. The process has high utilization efficiency, and the anhydration is realized.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

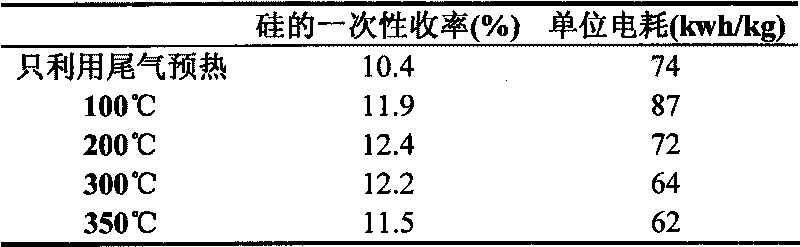

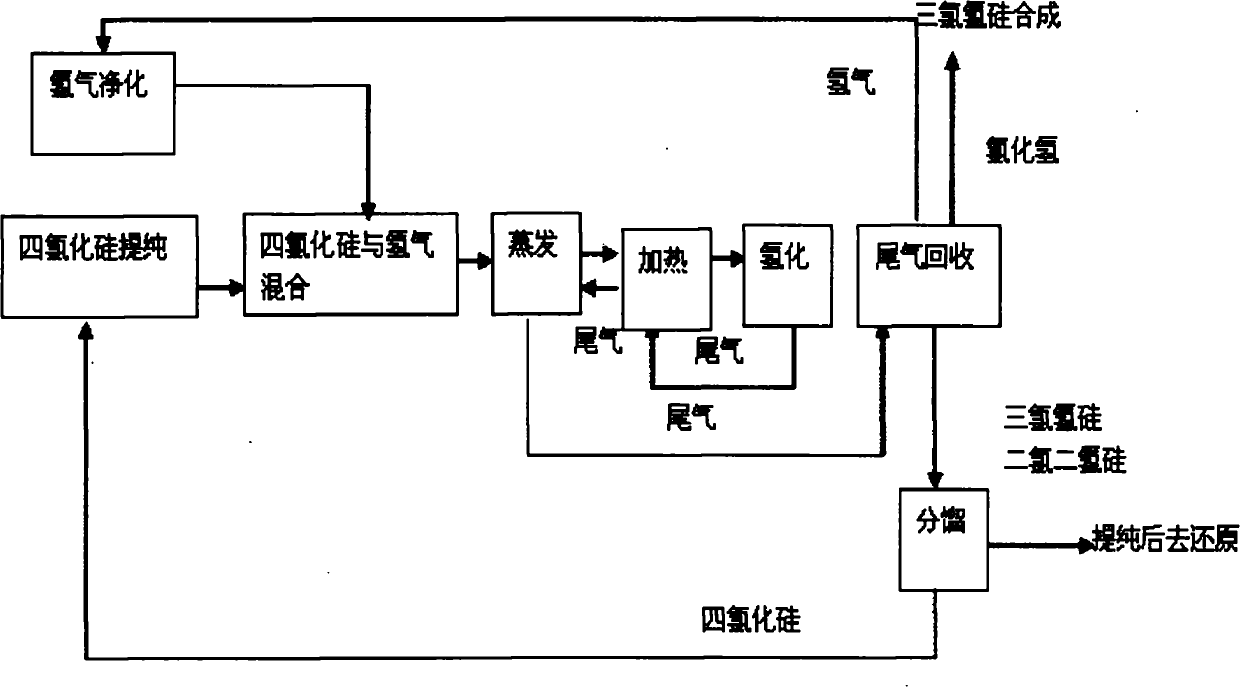

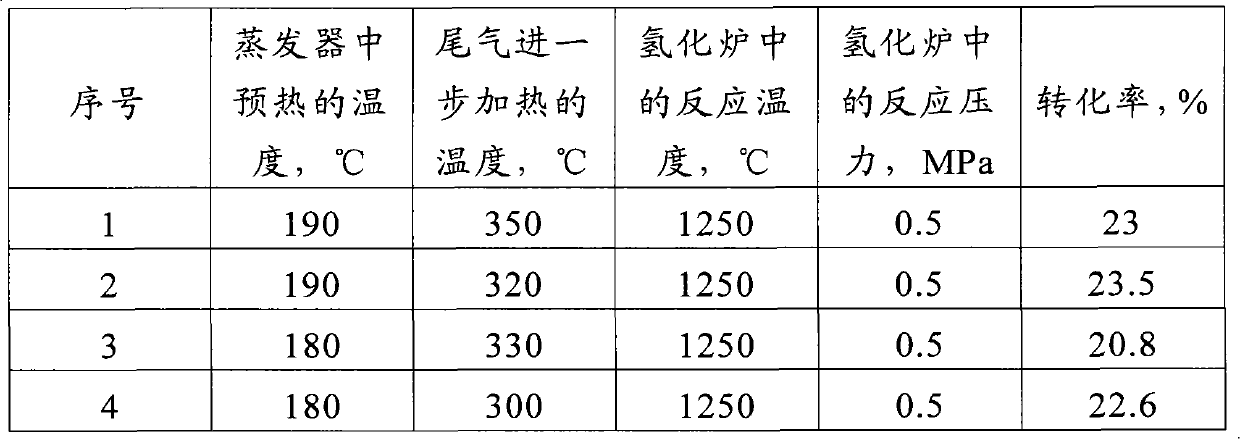

Method for producing trichlorosilane by using silicon tetrachloride

InactiveCN102020282AFully warmed upSave electricityHalogenated silanesPhysical chemistrySilicon tetrachloride

The invention provides a method for producing trichlorosilane by using silicon tetrachloride, which comprises the following steps of: a) refining the silicon tetrachloride; b) purifying hydrogen; c) mixing the silicon tetrachloride and the hydrogen; d) preheating the mixed gas of the silicon tetrachloride and the hydrogen by using one or two of steam and the tail gas of hydrogenation; e) hydrogenating the preheated mixed gas of the silicon tetrachloride and the hydrogen; and f) recovering the tail gas of the hydrogenation, and fractionating to obtain the trichlorosilane. In the method, before the silicon tetrachloride and the hydrogen are subjected to hydrogenation, the mixed gas of the silicon tetrachloride and the hydrogen is preheated by the steam and the tail gas of the hydrogenation, so that a needed temperature can be reached by consuming a little electricity during the hydrogenation, the energy source is saved, the hydrogenation has high speed and yield, and the reaction time is short. Therefore, the method is suitable for large-scale polycrystalline silicon production.

Owner:CHONGQING DAQO NEW ENERGY

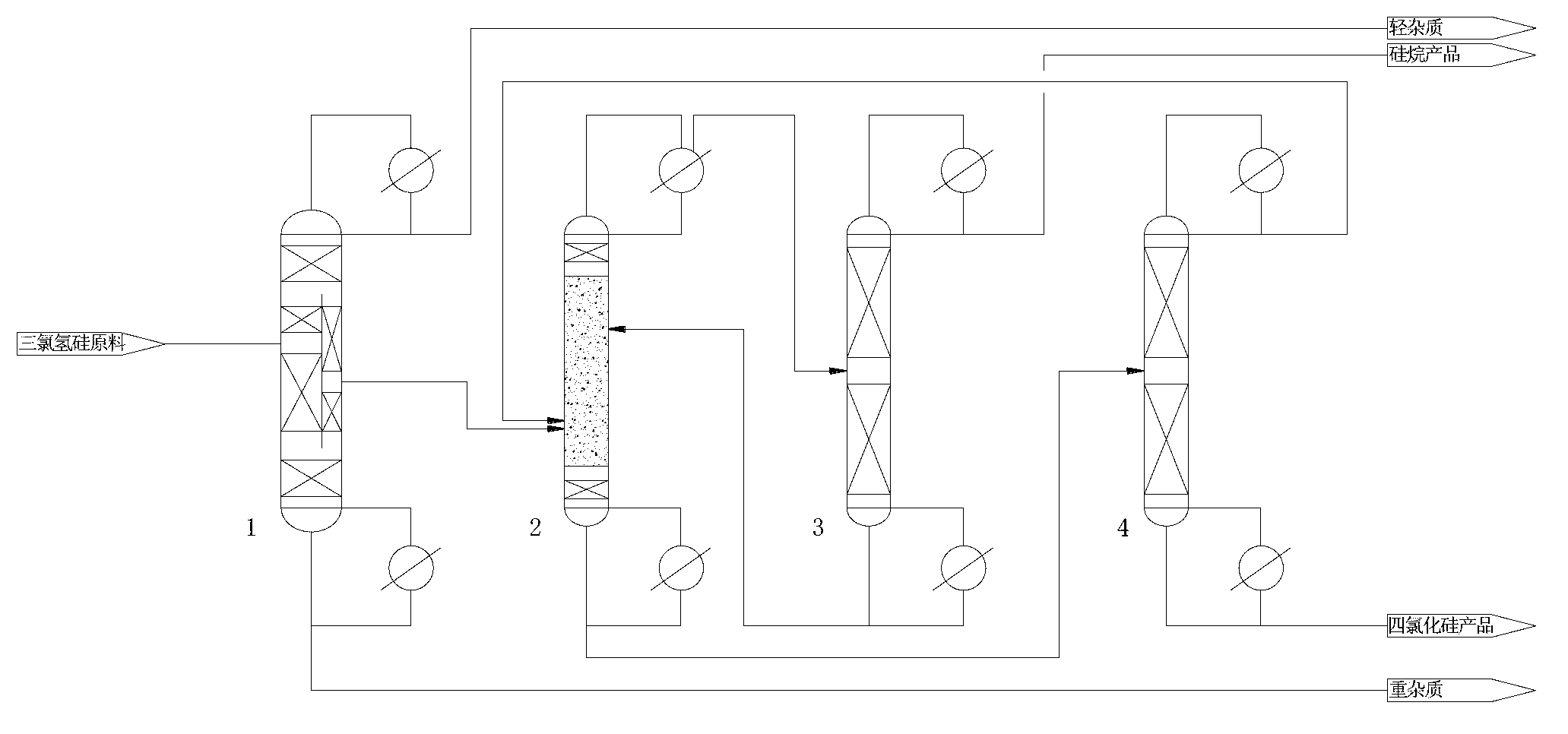

Process for rectifying trichlorosilane

InactiveCN102070147AGood removal effectEnhanced carbon removal capacityHalogenated silanesPhysical chemistrySilicon tetrachloride

The invention relates to a process for rectifying trichlorosilane. In the process, trichlorosilane feed liquor passes through two sieve plate rectifying towers and two filler rectifying towers in turn to be rectified so as to obtain a high-purity trichlorosilane product, and a silicon tetrachloride product also can be obtained during rectification. Due to the design of the sequence of the sieve plate rectifying towers and the filler rectifying towers and the setting of a reflux ratio parameter, capability of removing trace impurities which cannot be removed by the conventional process flow can be improved, capability of removing boron and carbon is obviously improved, the separation effect is better, and the requirements of polycrystalline silicon manufacturers are met.

Owner:乐山永祥硅业有限公司

Synthetic method and apparatus for trichlorosilane

ActiveCN106915747ALarge specific surface areaReduce difficultyHalogenated silanesPhysical chemistryHydrogen chloride

The invention discloses a synthetic method and apparatus for trichlorosilane. According to the method, silicon powder with a particle size in a range of 200 to 400 meshes is used for reaction with hydrogen chloride so as to synthesize trichlorosilane; the used silicon powder has a wide particle size range and is low in production cost and reduced in the difficulty coefficient of production; and since the silicon powder in a wide particle size range has low fluidizing gas velocity, the mole fraction of corresponding introduced hydrogen chloride can be reduced during preparation of trichlorosilane, so difficulty of and cost for tail gas recovery is lowered. Compared with silicon powder used in preparation of trichlorosilane in the prior art, the silicon powder in a particle size range of 200 to 400 meshes in the invention has a greater specific surface area, so a gas-solid contact area is increased and reaction intensity is improved; and thus, the production power of the synthetic method and apparatus for trichlorosilane in the invention is improved.

Owner:XINTE ENERGY

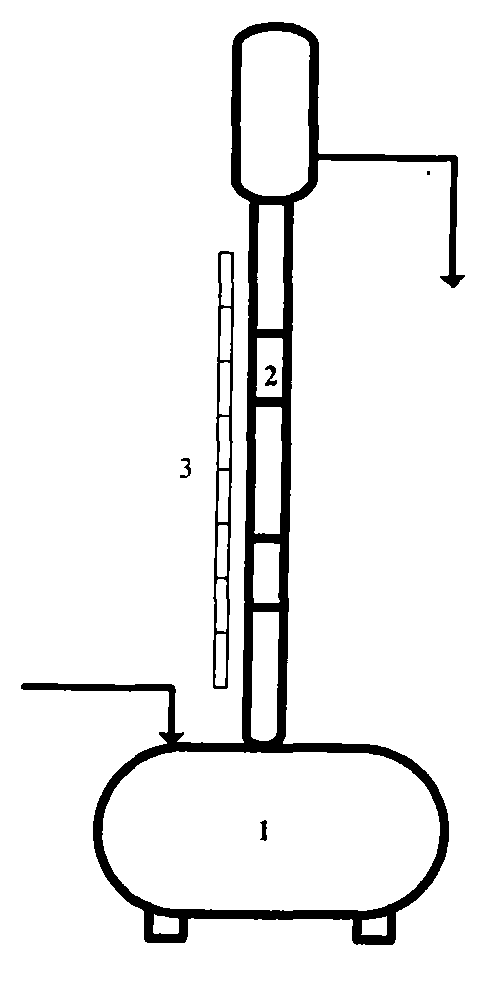

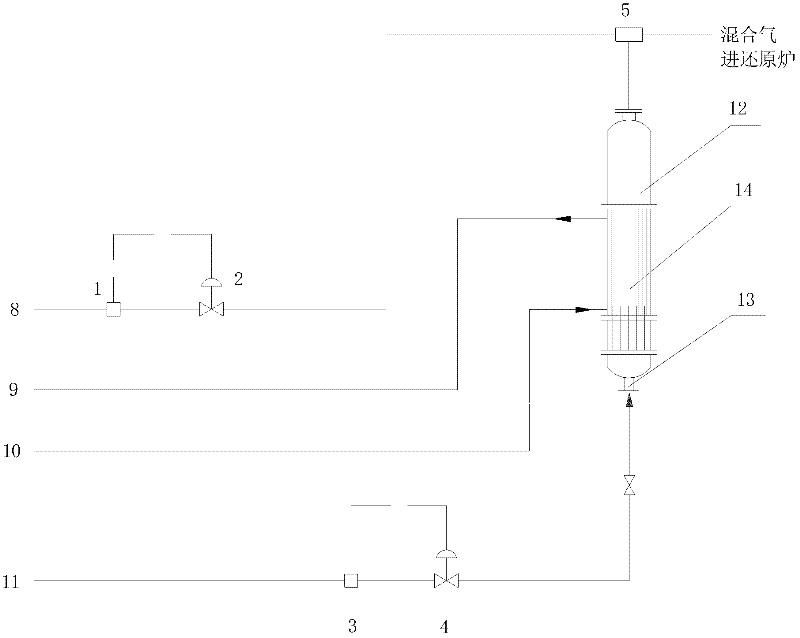

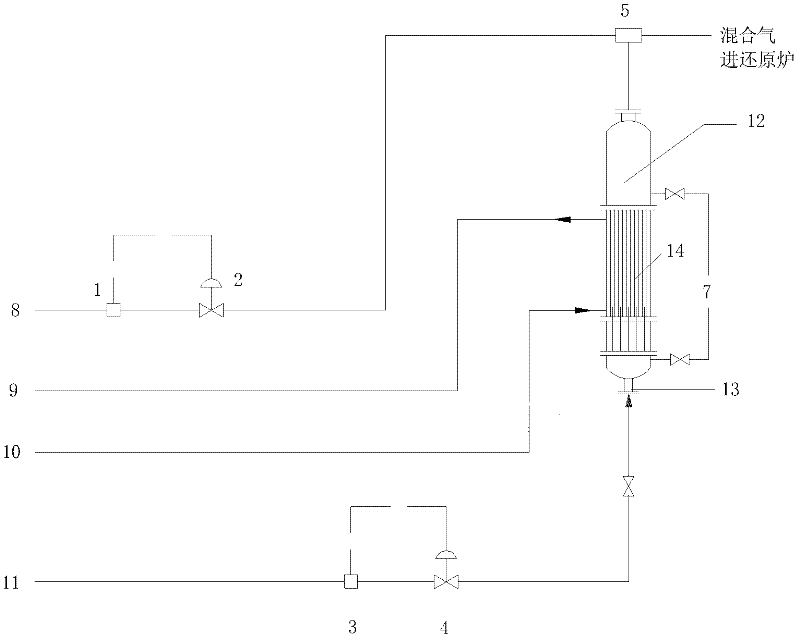

Trichlorosilane vaporization device

The invention relates to a polysilicon production device, in particular to a trichlorosilane vaporization device, and belongs to the technical field of polysilicon production. The trichlorosilane vaporization device of the present invention comprises an evaporator, a hydrogen delivery pipe, a trichlorosilane liquid delivery pipe, a trichlorosilane gas delivery pipe, a mixed gas delivery pipe, and a mixer, and the lower end of the evaporator is provided with trichlorosilane The silicon liquid inlet and the upper end are provided with a trichlorosilane gas outlet; the trichlorosilane liquid inlet is connected with the trichlorosilane liquid conveying pipe; the trichlorosilane liquid conveying pipe and the hydrogen conveying pipe are provided with a meter; the mixer They are respectively connected with the hydrogen gas delivery pipe, the trichlorosilane gas delivery pipe and the mixed gas delivery pipe. Using the trichlorosilane vaporization device of the present invention to vaporize trichlorosilane can obtain a mixed gas with a stable ratio and uniform mixing; the mixing of raw materials is more uniform, which is conducive to the uniform growth of silicon rods in the reduction reaction of the reduction furnace, The appearance quality of the produced crystal grains is better.

Owner:SICHUAN XINGUANG SILICON TECH

Separation device and separation method for removing silicon tetrachloride in organosilicon monomer azeotrope

PendingCN112028926AReduce loadReduce consumptionSilicon organic compoundsHalogenated silanesPtru catalystMeth-

The invention discloses a separation device and separation method for removing silicon tetrachloride in an organosilicon monomer azeotrope, the separation device comprises: a first separation tower for separating the organosilicon monomer azeotrope, a fixed bed reactor connected with the tower top of the first separation tower, wherein a tower top material of the first separation tower flows intothe fixed bed reactor and undergoes a reverse disproportionation reaction with a dichlorosilane product under the catalytic action of a catalyst to generate trichlorosilane, a second separation towerconnected with the fixed bed reactor and used for separating materials flowing out of the fixed bed reactor, wherein a trimethyl monochlorosilane product is obtained at the tower bottom of the secondseparation tower, and a dichlorosilane product is obtained at the tower top of the second separation tower. According to the method disclosed by the invention, the load of a rectifying device in the prior art can be greatly reduced, silicon tetrachloride azeotrope in the organic silicon monomer azeotrope is removed, and silicon tetrachloride is converted into trichlorosilane.

Owner:XINTE ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com