Reactive distillation method and equipment for preparing silane through direct disproportionation of trichlorosilane

A technology of trichlorosilane and disproportionation reaction, applied in halosilane, silicon halide compound, chemical industry, etc., can solve the problems of no process innovation, large energy consumption, lengthy process, etc., to avoid material separation, cyclic reaction, control Effect of running cost and process shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] Take the pilot scale 10t / y high-purity silane output for accounting and explanation.

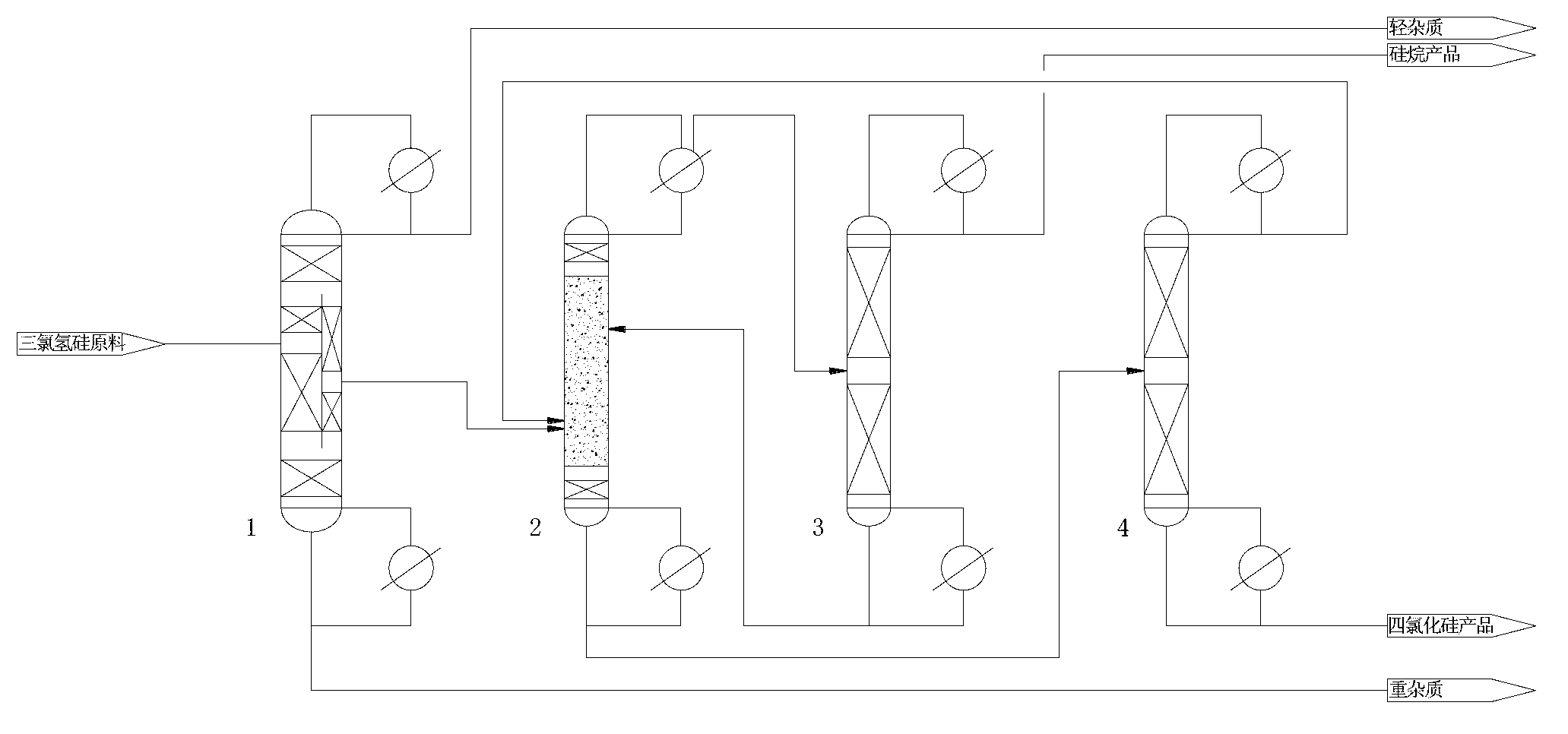

[0036] 25.4kg / h TCS raw material is pumped into the middle part of the trichlorosilane separator rectification tower (1). The upper part of the tower is filled with 3m high-efficiency structured packing as a common rectification section for separating light impurities; the lower part is filled with 3m high-efficiency structured packing As a public stripping section, it is used to separate heavy impurities; the middle part is divided by a partition with a height of 10m, and both sides are filled with 9m high-efficiency structured packing for feed pre-separation and product purification side extraction. The diameter of the rectification tower (1) with the trichlorosilane partition board is 150mm. The operating pressure is controlled at 0.6Mpa, the temperature at the top of the tower is 105°C, and the temperature at the bottom of the tower is 115°C. The top of the tower is cooled by circula...

example 2

[0041] It is calculated and explained based on the industrial production scale of 10000t / y high-purity silane output.

[0042] The 24.4t / h TCS raw material is pumped into the middle part of the trichlorosilane separator rectification tower (1). The upper part of the tower is filled with 5m high-efficiency structured packing as a common rectification section to separate light impurities; the lower part is filled with 5m high-efficiency structured packing As a common stripping section, it is used to separate heavy impurities; the middle part is divided by a partition with a height of 20m, and both sides are filled with 15m high-efficiency structured packing for feed pre-separation and product purification side extraction. The diameter of the trichlorosilane separator rectification tower (1) is 4.2m. The operating pressure is controlled at 0.1Mpa, the temperature at the top of the tower is 45°C, and the temperature at the bottom of the tower is 47°C. The top of the tower is cooled ...

example 3

[0047] The purity of the raw material refined trichlorosilane reaches 9N or more, and the industrial production scale is 10,000t / y of high-purity silane output for accounting.

[0048] 23.4t / h refined TCS enters the disproportionation reaction rectification tower (2), the middle of the tower is filled with four sections of catalyst with a structure of 16m in total, filled with basic anion exchange resin in a corrosion-resistant cloth bag, and made by rolling with the corrugated wire mesh packing. It plays a role of reactive distillation. The upper part is filled with 3m highly efficient structured packing as the rectification section to recover unreacted chlorosilane, and the lower part is filled with 3m highly efficient structured packing as the stripping section to initially separate TCS and STC. The diameter of the disproportionation reaction distillation tower (2) is 3.4m. The operating pressure is controlled at 0.2Mpa, the tower top temperature is controlled at 0°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com