Method adopting trichlorosilane and dichlorosilane mixed raw materials to produce polycrystalline silicon

A technology of dichlorodihydrogensilicon and trichlorohydrogensilicon, which is applied in the direction of silicon and the like, can solve the problems of difficulty in processing the by-product dichlorodihydrogensilicon, and achieve the effects of large processing capacity, reducing investment and increasing economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

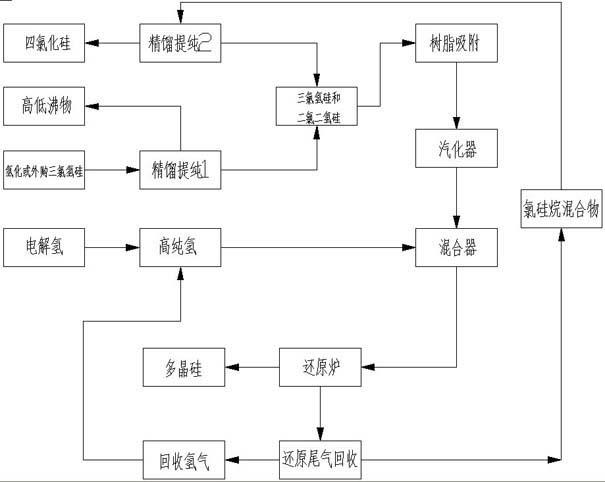

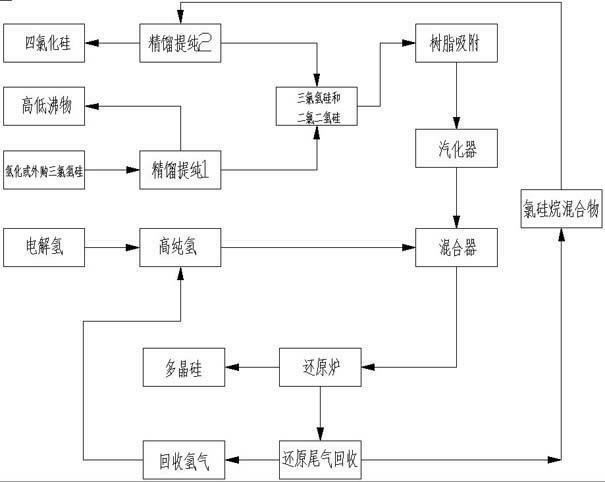

[0039] The specific implementation steps of the present invention will be further described below in conjunction with the accompanying drawings.

[0040] Process flow of the present invention is roughly as figure 1 . Include the following steps:

[0041] In step 1, the supplemented trichlorosilane raw material is rectified and purified in a rectification tower to obtain a trichlorosilane raw material with a purity greater than 99.995%; in this step, the trichlorosilane raw material is purchased or recovered from four Silicon chloride is produced by cold hydrogenation, and the purity of the supplemented trichlorosilane raw material cannot meet the requirements of the reduction furnace, so three sets of rectification towers need to be installed for continuous rectification and purification. Specifically, the following steps are required: firstly, the supplementary trichlorosilane with an initial purity ≥ 98% is subjected to preliminary rectification and purification in a recti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com