Catalyst, preparation method and application thereof

A catalyst and solvent technology, which is applied in the field of catalyst preparation, can solve the problems of poor catalyst stability, reduced activity, and poor stability, and achieve the effects of reducing the purification process, improving catalyst activity, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

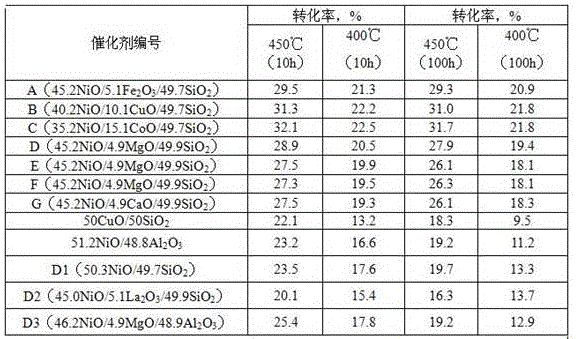

Examples

preparation example Construction

[0019] The invention provides a method for preparing a catalyst, wherein the method comprises: combining a soluble nickel salt, a soluble salt compound of metal M, a silicon source capable of providing silicon dioxide, and a precipitating agent capable of precipitating nickel and / or metal M ions Contacting in a solvent, filtering the contacted product, drying and calcining the obtained solid in sequence, wherein, the M is selected from one or more of Group VIII metals except Ni, IIB, IIA.

[0020] In the present invention, the amount of the soluble nickel salt, the silicon source, and the soluble salt compound of metal M can be selected in a wide range, and can be determined according to the amount of each component in the catalyst to be obtained. For the present invention, the preferred The amount of the soluble nickel salt, the silicon source and the soluble salt compound of the metal M makes the prepared catalyst, based on the total weight of the catalyst, in terms of oxides...

Embodiment approach

[0034] According to a preferred embodiment of the present invention, the present invention adopts following method to prepare catalyst:

[0035] 1) The soluble nickel salt and the soluble salt compound of metal M are prepared into aqueous solutions respectively, and the soluble nickel salt solution and the soluble salt compound aqueous solution of metal M are mixed to obtain a mixed solution, and a silicon source capable of providing silicon dioxide is added to the mixed solution A slurry is obtained in the solution, and the pH value of the slurry is adjusted;

[0036] 2) Then add a precipitant solution for contact, then filter, dry and roast.

[0037] In the present invention, in order to make the contact more sufficient, the contact is carried out under stirring conditions. In the examples of the present invention, the mixing and contacting of various substances are also carried out under stirring conditions, which will not be specifically emphasized later.

[0038] The inv...

Embodiment 1

[0048] (1) Dissolve 56.5 kilograms of nickel nitrate hexahydrate and 25 kilograms of ferric nitrate nonahydrate in deionized water to prepare 500 liters of solution, and add 320 kilograms of sodium silicate aqueous solution with a concentration of 10% by weight to the above mixed salt solution , mix uniformly to obtain the slurry, the pH value of the slurry is adjusted to 6 with a sodium hydroxide aqueous solution with a concentration of 5% by weight; 43 kilograms of anhydrous sodium carbonate are dissolved with 400 liters of deionized water to obtain an aqueous solution of sodium carbonate;

[0049] (2) Add the above-mentioned sodium carbonate aqueous solution and the slurry into a 2000-liter reactor for contacting, the contacting temperature is 80° C., and the pH is adjusted with a concentration of 5% by weight aqueous sodium hydroxide solution so that the contacting pH value is 7, and the contacting temperature is 7. After 4 hours, the solid was obtained by filtration, dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com