Method for preparing silicon tetrachloride for optical fiber

A silicon tetrachloride and optical fiber technology, applied in the direction of halogenated silicon compounds, etc., can solve the problems of difficult removal, clogging of the reaction device, increase in content, etc., and achieve the effect that the degree of completeness is easier to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

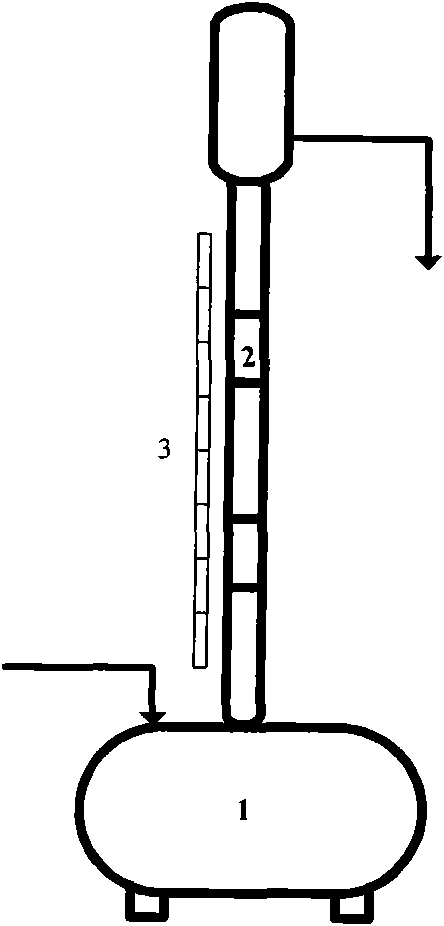

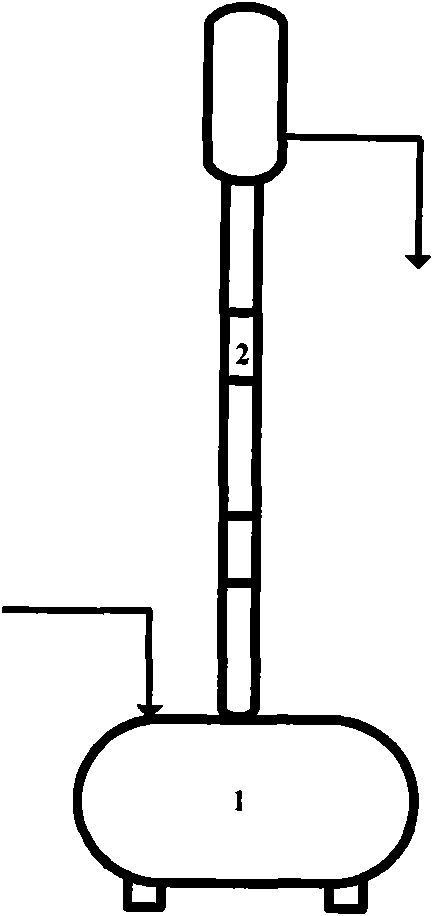

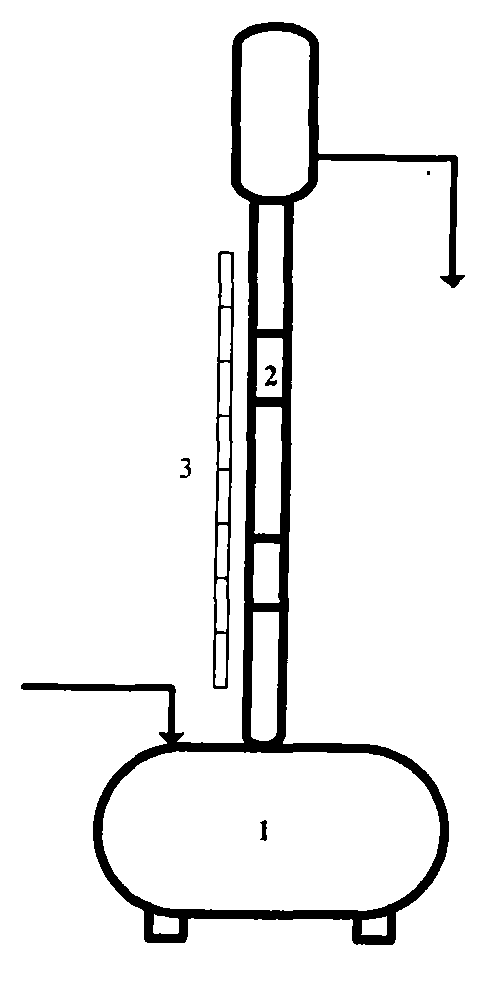

Image

Examples

Embodiment 1

[0035] Introduce nitrogen into the system as a protective atmosphere, the material in the tower is heated, the silicon tetrachloride liquid is converted into gas, and condensed by the top condenser. During the period, when the material on the tower column is irradiated by a 4kw mercury lamp, chlorine gas corresponding to the amount of raw material (50L) is introduced into the tower kettle, and after reflux for 5 hours, the material is taken, and the set reflux ratio is 3:1. According to the amount of raw materials, take out the low boiling point and middle distillate according to the corresponding proportion, the taking out speed is 1~3 kg / hour, and keep 1 / 3 of the high boiling point.

[0036] Press the middle distillate into a 3-meter-high, 80-mm-diameter quartz plate rectification tower, pass inert or inert gas into the rectification tower, control the temperature of the tower kettle and tower column between 55 and 70°C, and complete the process after 5 hours After reflux, s...

Embodiment 2

[0038]Introduce argon gas into the system as a protective atmosphere, the material in the tower kettle is heated, the silicon tetrachloride liquid is converted into gas, and condensed by the top condenser, the temperature of the tower kettle is between 55 and 70°C, and the temperature at the top of the tower is between 55 and 70°C between. When the material on the tower column is irradiated by a 2kw mercury lamp, chlorine gas of a corresponding ratio to the raw material amount (30L) is introduced into the tower kettle, and after reflux for 1 hour, the material is taken, and the set reflux ratio is 5:1. According to the amount of raw materials, the low boiling point and intermediate products are taken out in corresponding proportions, the taking out speed is 1-2 kg / hour, and 1 / 4 of the high boiling point is reserved.

[0039] Press the intermediate product into a 3-meter-high, 60-mm-diameter quartz plate rectification tower, pass inert or inert gas into the rectification tower,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com