Fully automatic battery code spaying grouping device

A fully automatic, coding technology, applied in typewriters, printing, etc., can solve the problems of large area occupied by equipment, precious space in the workshop, and prone to defective products, so as to save labor, maintain consistency, and realize automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the specific implementations described here are only used to illustrate and explain the description, and are not intended to limit the present invention.

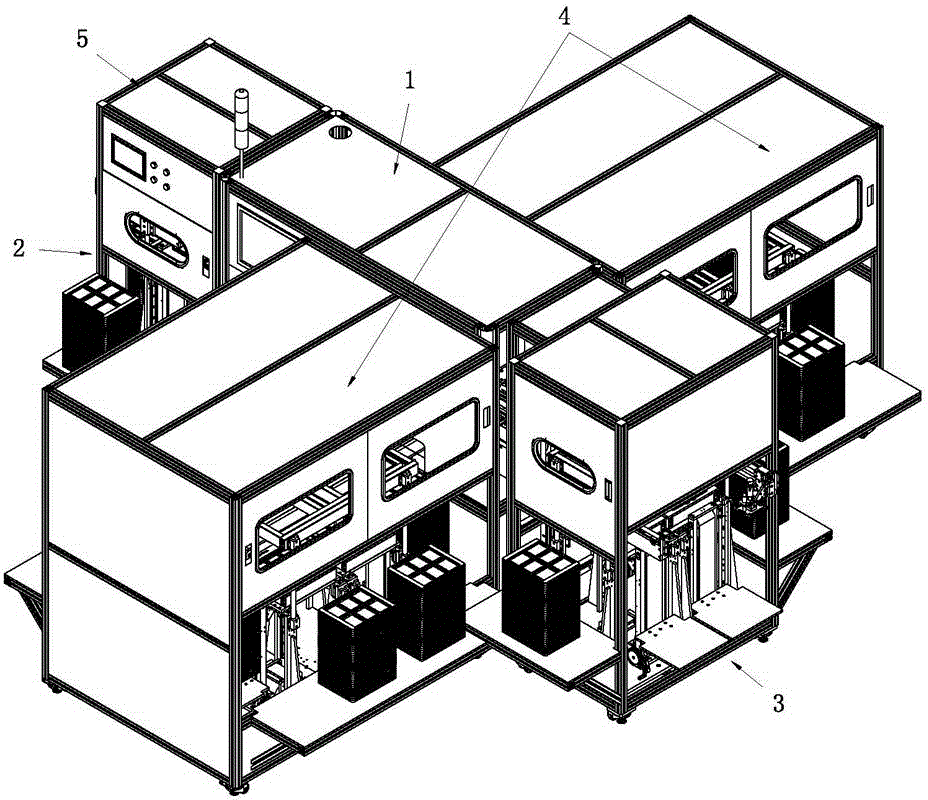

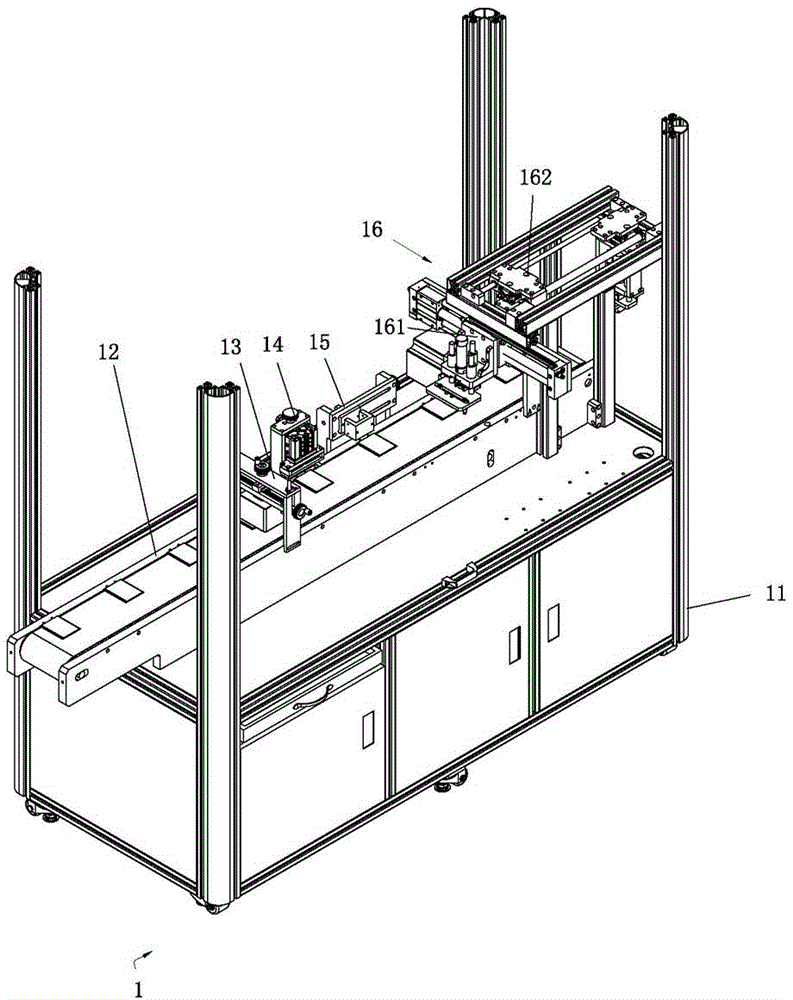

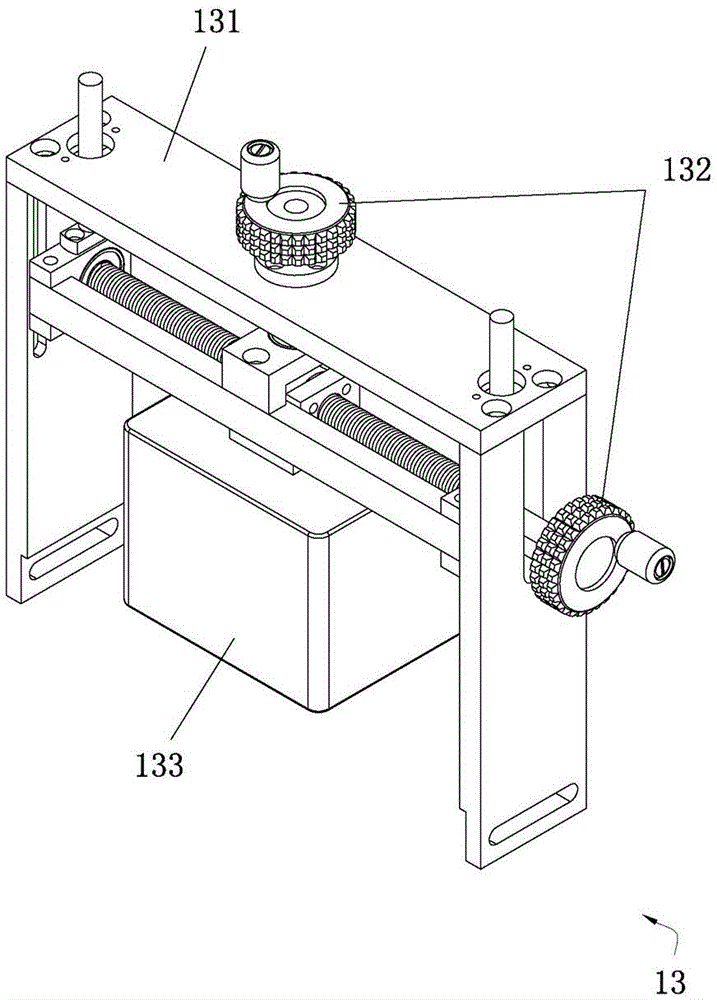

[0045] figure 1 A schematic diagram of the assembly structure according to an embodiment of the present invention is shown. Among them, there are three groups of group receiving mechanisms, which are used to accurately sort and classify semi-finished batteries of different parameter levels.

[0046] The semi-finished battery in this embodiment is a sheet-shaped polymer battery, and the electrodes of the battery are located on one side of the battery.

[0047] The coding information in this embodiment includes Arabic numerals, one-dimensional barcodes, and two-dimensional barcodes.

[0048] see figure 1 , a fully automatic battery coding grouping device provided in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com