Production method of pre-hardened high-speed steel products and production device thereof

A production method and technology of a production device, which are applied in the field of high-speed steel pre-hardened material production methods and production devices, can solve the problems of difficult temperature control, uneven performance of workpieces, easy overheating or overburning of workpieces, etc., and achieve stable structure and performance. , the effect of reducing inventory and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

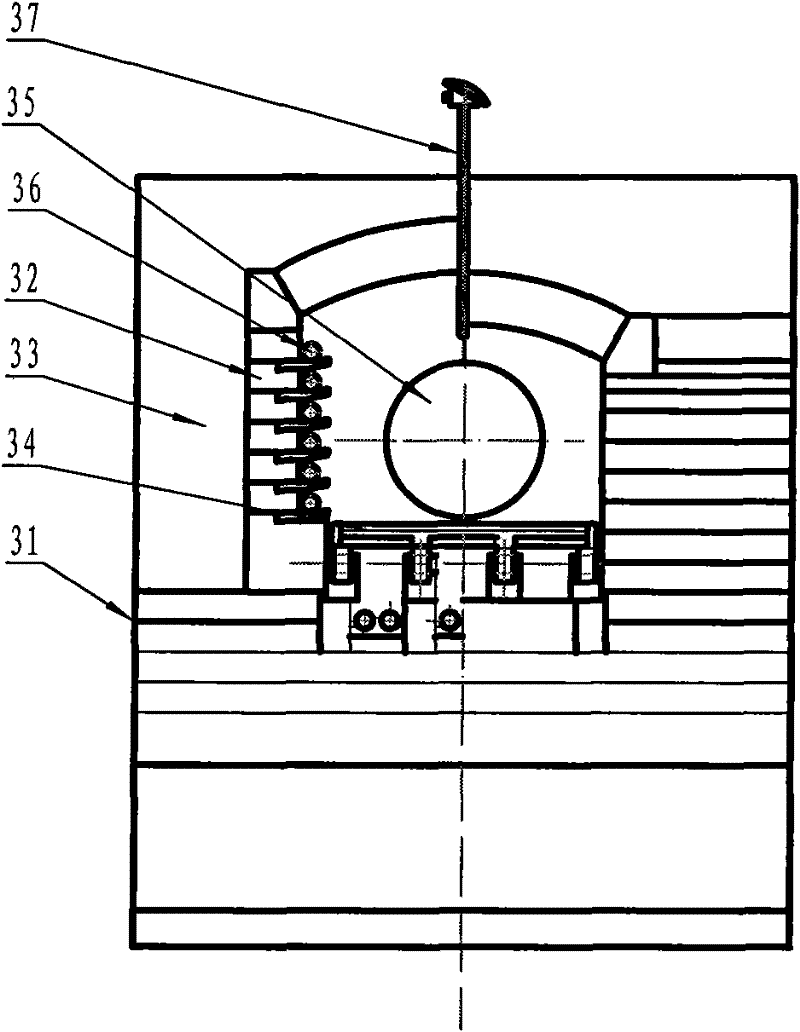

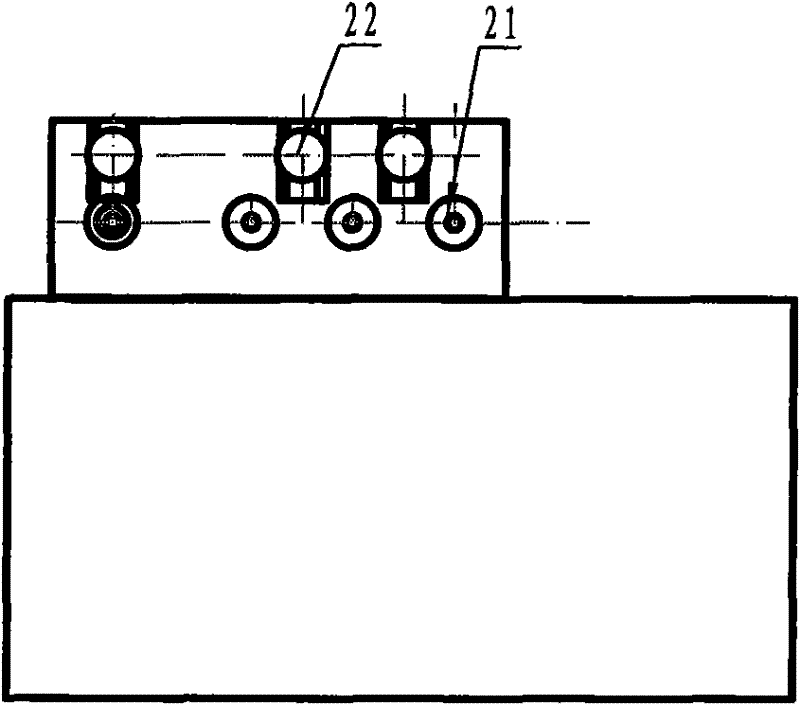

[0054] Example, a high-speed steel pre-hardened material production method. The production method uses high-speed steel wire as the raw material, and each process is continuously produced without interruption. The raw material is pre-straightened by a straightening machine first, and the damping roller of the straightening machine is used. Apply pre-stress, quench and heat the pre-straightened raw material in a controlled atmosphere or in a salt bath furnace or induction furnace. The heating temperature is 1120-1260℃, and the operating speed is 50-2000mm / min. After quenching, use a wire drawing die to The high-speed steel wire undergoes a small amount of deformation, the deformation is 0-0.1mm, and then is quenched. The steel wire is press-cooled with a straightening machine and a water cooling jacket to reduce cooling deformation. At the same time, the quenched steel wire is straightened. Perform the first tempering at 460℃-660℃ to transform the retained austenite into martensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com