Control process for producing non-woven fabric

A non-woven fabric and process technology, applied in the field of control process of non-woven fabric production, can solve the problems of dependence on imports, late start of spunlace non-woven industry, etc., to achieve reduced floor space, good mixing effect, and hot air penetration strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

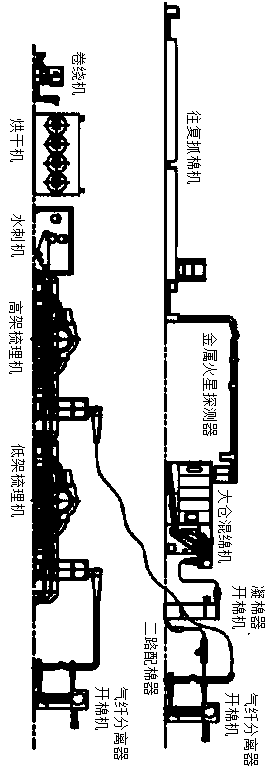

Image

Examples

Embodiment 1

[0034] A control process for the production of nonwovens, characterized in that:

[0035] (1) grabbing step;

[0036] (3) Pre-opening step

[0037] The main function of the pre-opening step is to decompose the larger fiber bundles into smaller fiber bundles, which is beneficial to the removal of impurities and lays the foundation for the mixing equipment to improve the mixing effect;

[0038] (3) Mixing step

[0039] In the processing flow of non-woven fabrics, there are two commonly used mixing equipments: large bin blender and multi bin blender, and users can choose the appropriate model according to actual needs;

[0040] (4) Fine opening and loosening steps

[0041] The main function of the fine opening equipment is to decompose the fiber bundles into small and uniform fiber bundles suitable for the feeding requirements of the carding machine, and remove part of the impurities according to the impurities in the fibers;

[0042] (5) Finishing cotton box steps

[0043] ...

Embodiment 2

[0059] A control process for the production of nonwovens, characterized in that:

[0060] (1) grabbing step;

[0061] (4) Pre-opening step

[0062] The main function of the pre-opening step is to decompose the larger fiber bundles into smaller fiber bundles, which is beneficial to the removal of impurities and lays the foundation for the mixing equipment to improve the mixing effect;

[0063] (3) Mixing step

[0064] In the processing flow of non-woven fabrics, there are two commonly used mixing equipments: large bin blender and multi bin blender, and users can choose the appropriate model according to actual needs;

[0065] (4) Fine opening and loosening steps

[0066] The main function of the fine opening equipment is to decompose the fiber bundles into small and uniform fiber bundles suitable for the feeding requirements of the carding machine, and remove part of the impurities according to the impurities in the fibers;

[0067] (5) Finishing cotton box steps

[0068] ...

Embodiment 3

[0084] A control process for the production of nonwovens, characterized in that:

[0085] (1) grabbing step;

[0086] (5) Pre-opening step

[0087] The main function of the pre-opening step is to decompose the larger fiber bundles into smaller fiber bundles, which is beneficial to the removal of impurities and lays the foundation for the mixing equipment to improve the mixing effect;

[0088] (3) Mixing step

[0089] In the processing flow of non-woven fabrics, there are two commonly used mixing equipments: large bin blender and multi bin blender, and users can choose the appropriate model according to actual needs;

[0090] (4) Fine opening and loosening steps

[0091] The main function of the fine opening equipment is to decompose the fiber bundles into small and uniform fiber bundles suitable for the feeding requirements of the carding machine, and remove part of the impurities according to the impurities in the fibers;

[0092] (5) Finishing cotton box steps

[0093] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com