Efficient grooving device for PE corrugated pipe

A technology of slotting equipment and bellows, which is applied in the field of PE polymer pipe processing, can solve the problems of manual slotting, large operating labor force, rough production, etc., to ensure drainage permeability indicators, save labor costs, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

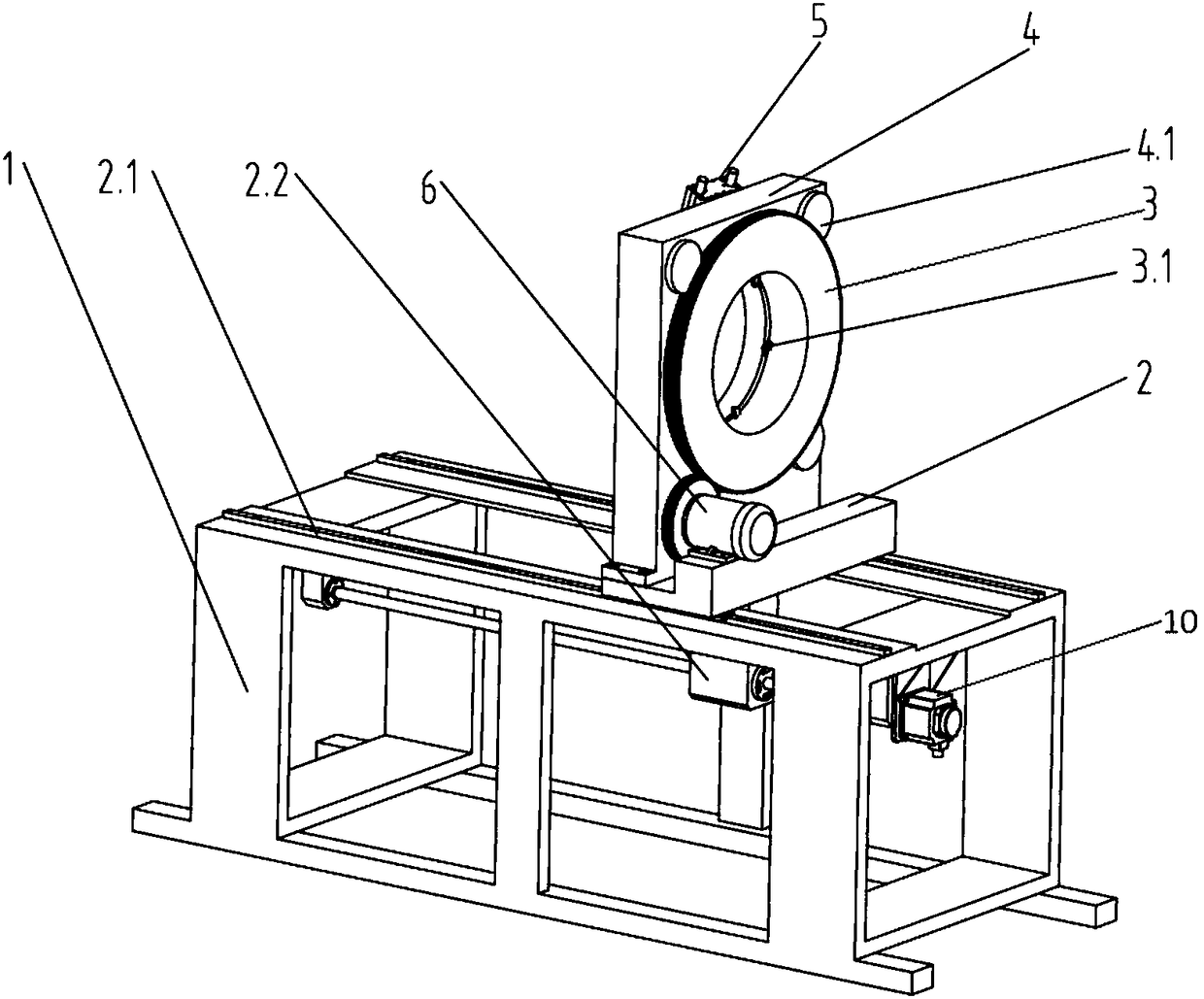

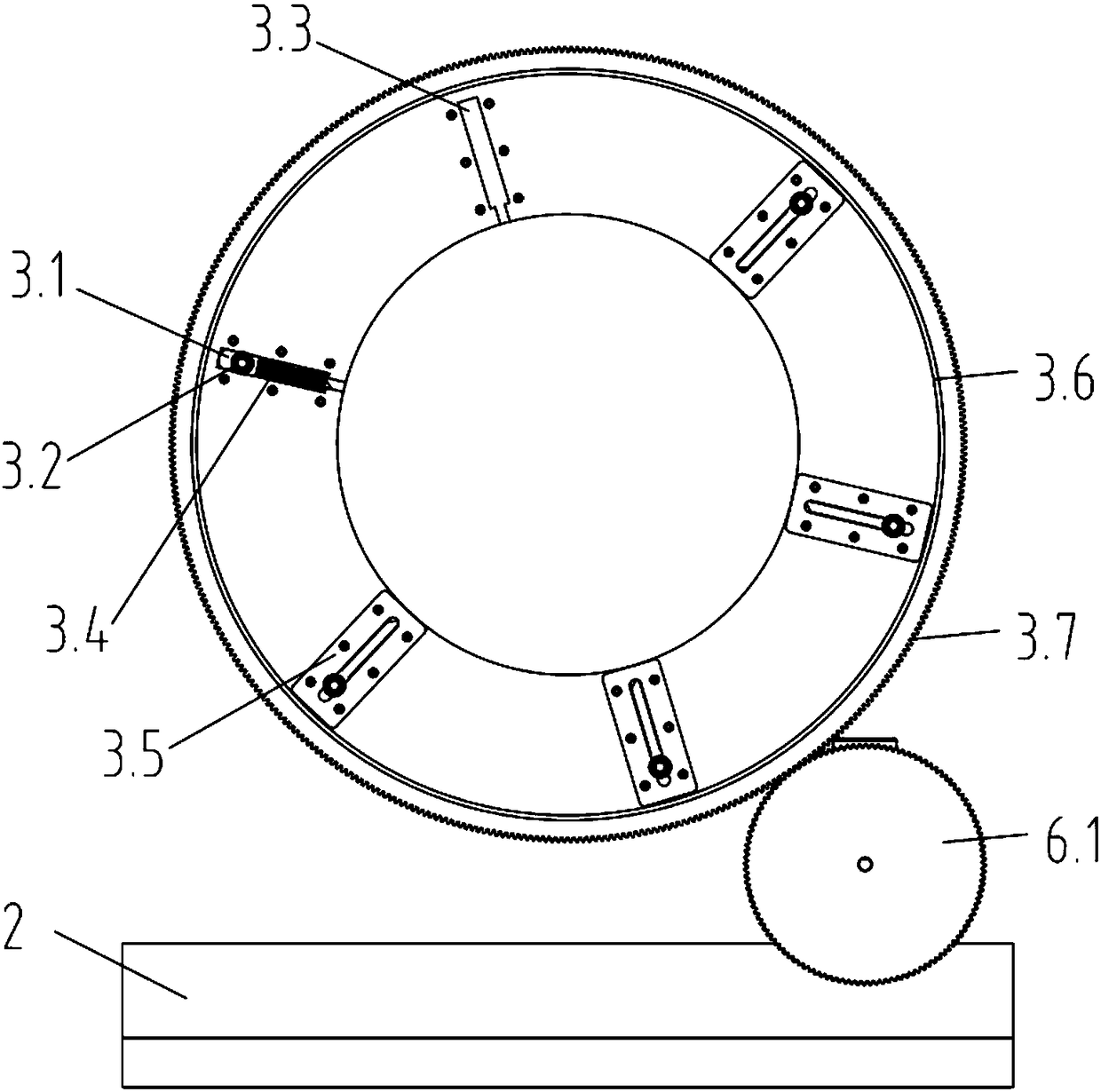

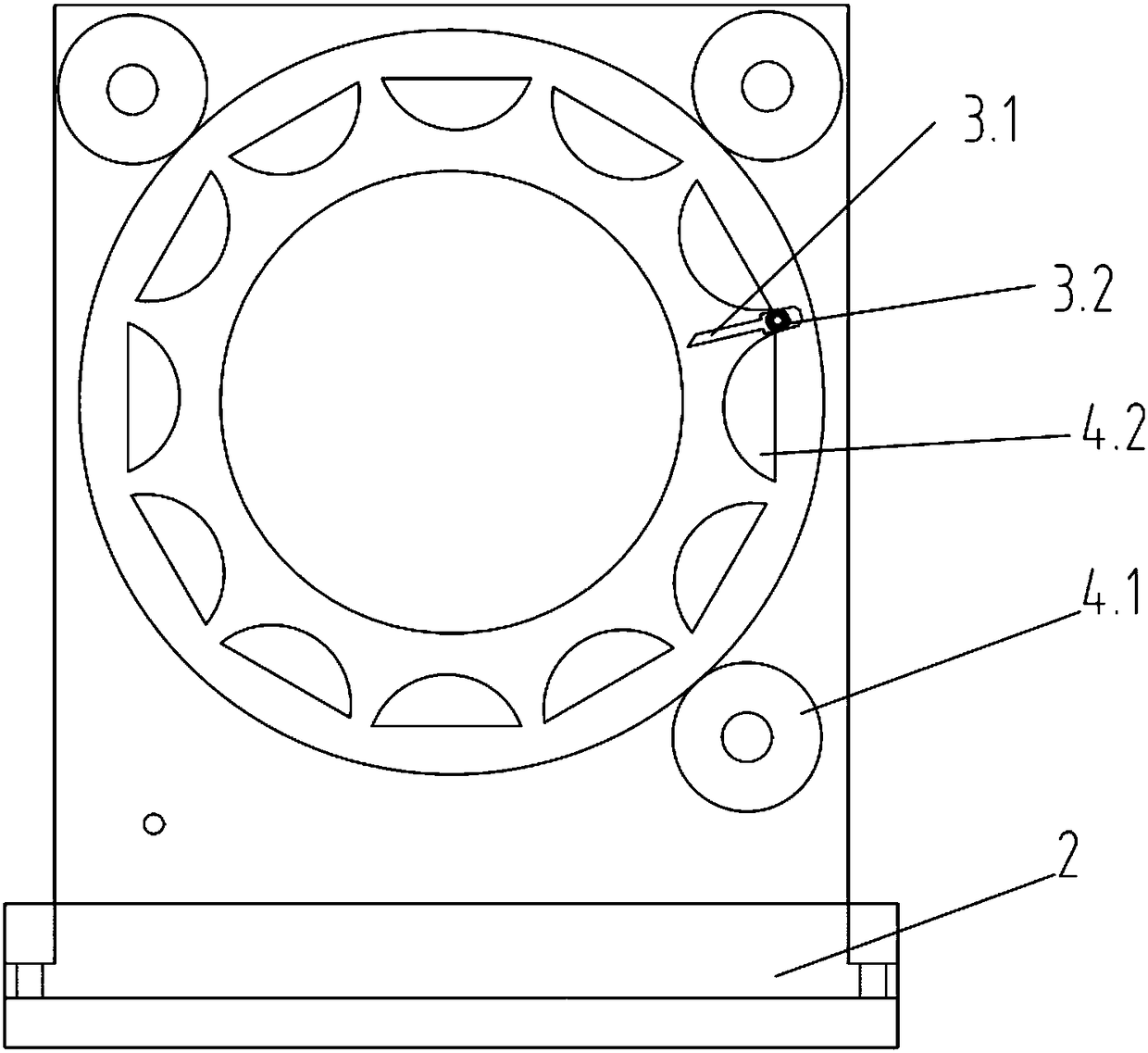

[0025] Such as figure 1 , figure 2 As shown, a high-efficiency slotting equipment for PE corrugated pipes includes a frame 1, a synchronous slide table 2, a rotary cutter head 3, a cam frame 4, a clamping cylinder 5 and a power motor 6, and the frame 1 is There is a pair of linear slide rail group 2.1, and a synchronous sliding table 2 is installed on the linear sliding rail group 2.1. The bottom of the synchronous sliding table 2 is provided with a screw seat 2.2, and a screw is inserted into the screw seat to rotate. The shaft of the servo motor is connected, and the servo motor can drive the synchronous slide table 2 to move forward and backward for a certain distance through the screw mandrel. The power motor 6 and the cam frame 4 are arranged on the describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com