Vacuum paint drawing and vacuum fast drying paint device and process for inner cavity of cooler for transformer

A technology for radiators and transformers, which is applied to the device for coating liquid on the surface, pretreatment of the surface, coating, etc. It can solve the problems of exhaust gas emission pollution, no guarantee of inner cavity quality, and time-consuming, so as to improve production efficiency and protect the environment. Improve the effect and protect the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

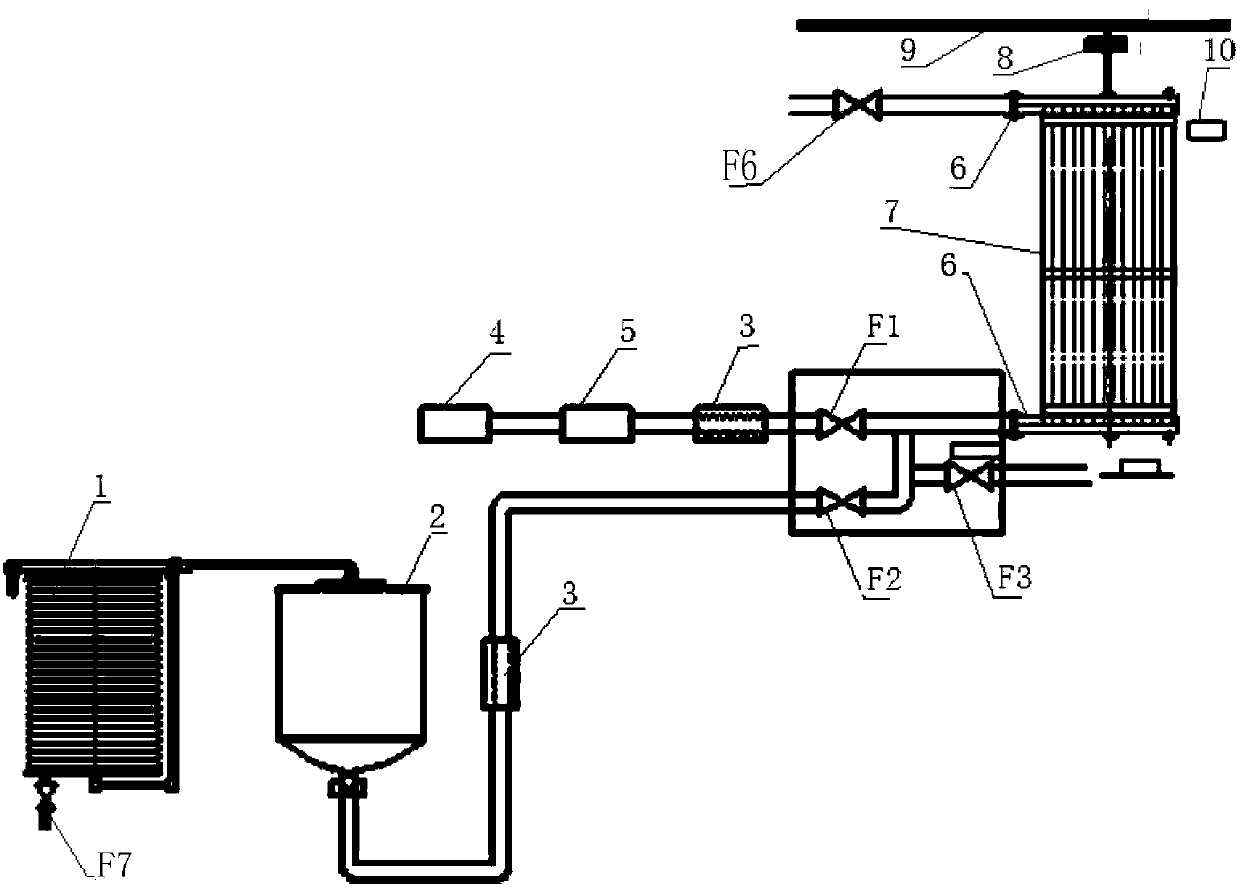

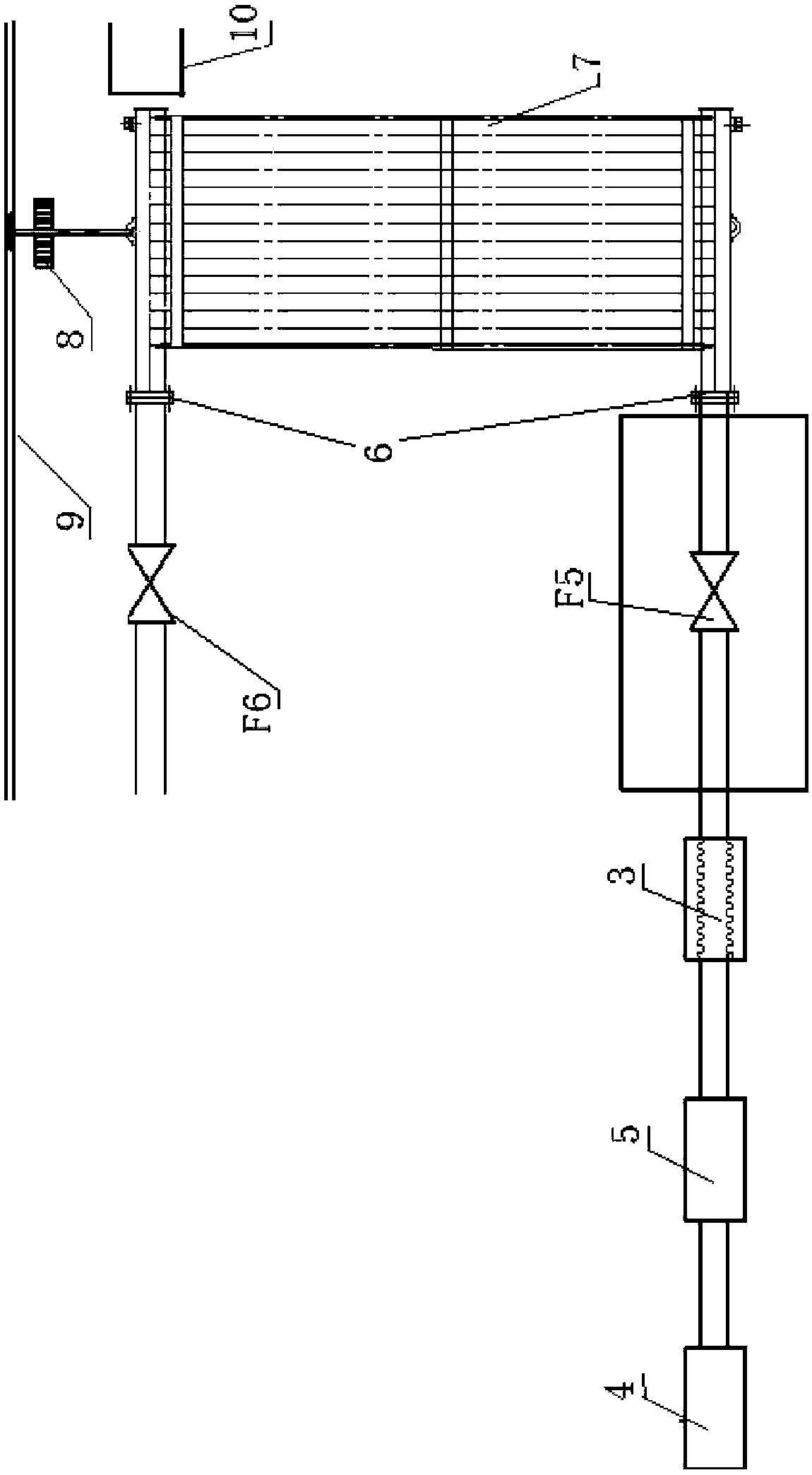

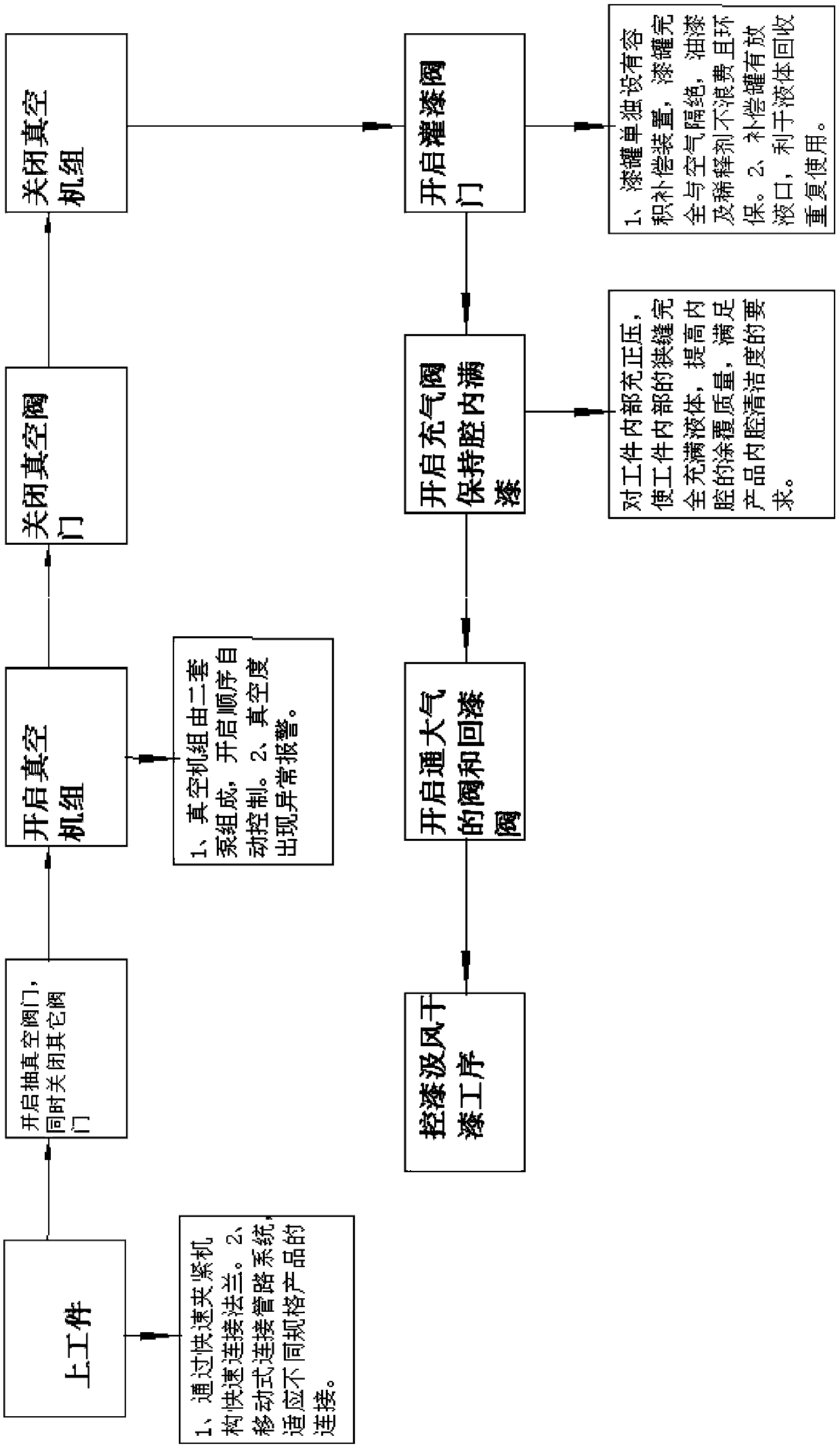

[0014] The arrangement sequence of the equipment of the present invention: including paint storage tank, vacuum system, process control system, exhaust gas recovery and treatment system, track, transmission chain and its motor unit, air duct, workpiece vehicle 9 hanging on the transmission line and control system are arranged on the top of the workshop. The lifting electric hoist 8 is characterized in that the equipment is arranged in the order along the transmission line: the vacuum paint extraction equipment 2, the exhaust fan unit 10, and then the equipment connected to the vacuum quick-drying paint process, all have air ducts connected to the tail gas recovery treatment system; the vacuum method paint extraction equipment , add an exhaust fan unit, and then connect the equipment for the quick-drying paint process; and there is an air duct connected to the exhaust gas recovery treatment system.

[0015] Vacuum pumping equipment: see figure 1 , the vacuum pumping equipment 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com