Preparation method for transparent conductive metal network

A metal network, transparent and conductive technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as insoluble resin, damage, nanowire substrate detachment, etc., to achieve online production and avoid engraving The effect of eclipse, active connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

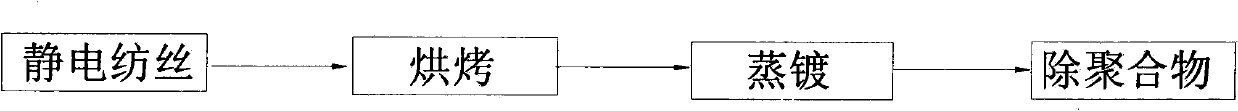

Method used

Image

Examples

Embodiment 1

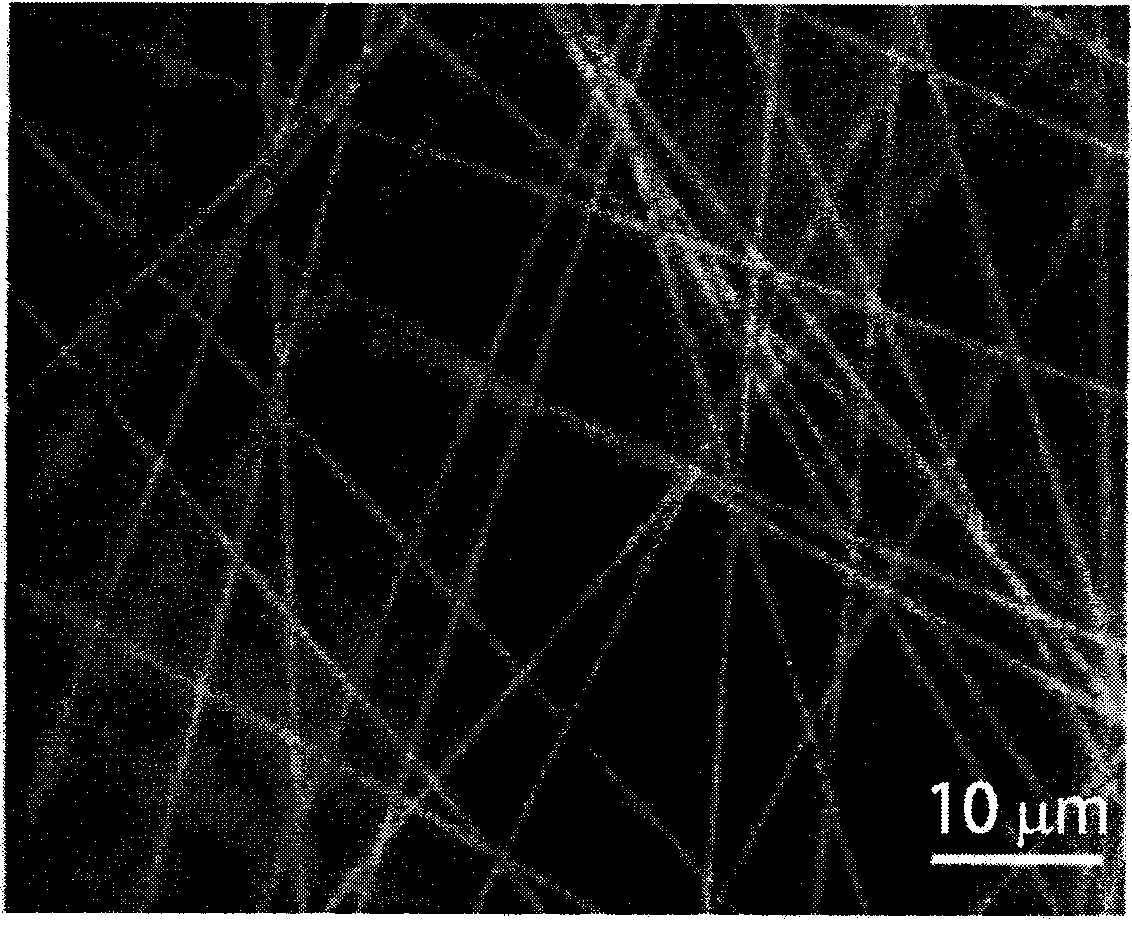

[0031] Preparation of polyvinyl alcohol nanofiber network:

[0032] First, take 2 grams of polyvinyl alcohol in 20 grams of water, heat and stir to dissolve until uniform, transfer it to a 30 ml syringe after it is completely dissolved, place it under 15kV high voltage, perform electrospinning, and arrange it in an orderly manner according to the required pattern A polyvinyl alcohol nanofiber network with a diameter of about 200 nm and a length of about 2 cm was obtained; the obtained polymer fiber network was then baked at 80° C. for 20 minutes to obtain a dried fiber network.

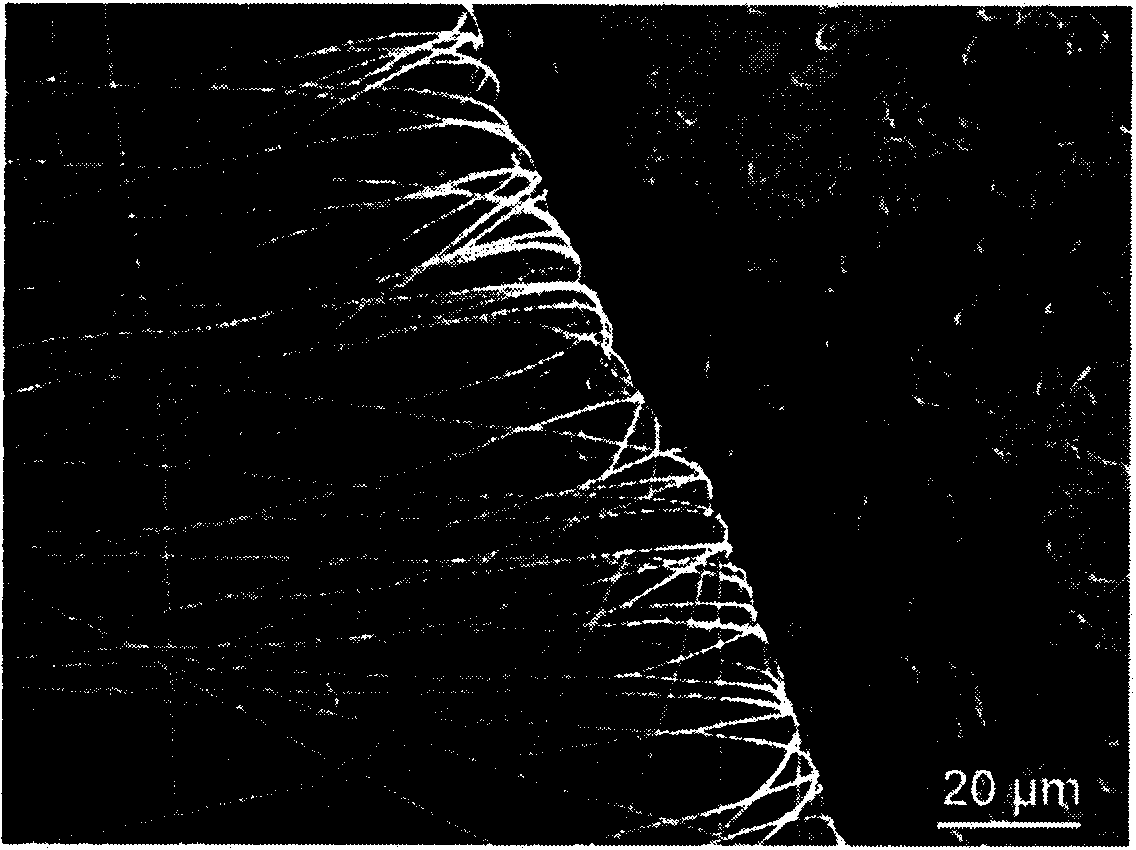

[0033] Preparation of metal conductive network:

[0034]The obtained dried polyvinyl alcohol nanofiber network is placed in a magnetron sputtering furnace, and a silver layer with a thickness of 40 nanometers is sputtered on the surface of the polyvinyl alcohol nanofiber network at a temperature of 60 ° C to obtain a silver-polyvinyl alcohol nanofiber network. fiber composite network. Then put this ...

Embodiment 2

[0040] Firstly, take 2.4 grams of polyvinylpyrrolidone, heat and stir it in 20 grams of water to dissolve until uniform, transfer it to a 30 ml syringe after it is completely dissolved, place it under 15kV high voltage, conduct electrospinning, and arrange it in an orderly manner according to the required pattern A polyvinylpyrrolidone nanofiber network with a diameter of about 150 nm and a length of about 3 cm was obtained; the obtained polymer fiber network was then baked at 60° C. for 30 minutes to obtain a dried fiber network.

[0041] Preparation of metal conductive network:

[0042] The obtained dried polyvinylpyrrolidone nanofiber network is placed in a magnetron sputtering furnace, and a gold layer with a thickness of 20 nanometers is sputtered on the surface of the polyvinylpyrrolidone nanofiber network at a temperature of 60 ° C to obtain gold-polyvinylpyrrolidone nanofiber network. fiber composite network. Then put this composite network structure in an ethanol sol...

Embodiment 3

[0046] First, take 1.5 grams of hydroxypropyl methylcellulose in 20 grams of water, heat and stir to dissolve until uniform, transfer it to a 30 ml syringe after it is completely dissolved, place it under a high voltage of 15kV, and carry out electrospinning, and carry out organic spinning according to the required pattern. A hydroxypropyl methylcellulose nanofiber network with a diameter of about 250 nanometers and a length of about 5 cm can be obtained by sequential arrangement; then the obtained polymer fiber network is baked at 60°C for 30 minutes to obtain a dried fiber network .

[0047] Preparation of metal conductive network:

[0048] The obtained dried hydroxypropyl methylcellulose nanofiber network is placed in a magnetron sputtering furnace, and a copper coating with a thickness of 50 nanometers is sputtered on the surface of the polyvinylpyrrolidone nanofiber network at a temperature of 60 ° C to obtain copper- Hydroxypropyl methylcellulose nanofiber composite net...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com