Labeling device

A transfer device and labeling technology, which is applied to labeling machines, labels, packaging, etc., can solve the problems that high-speed material webs cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

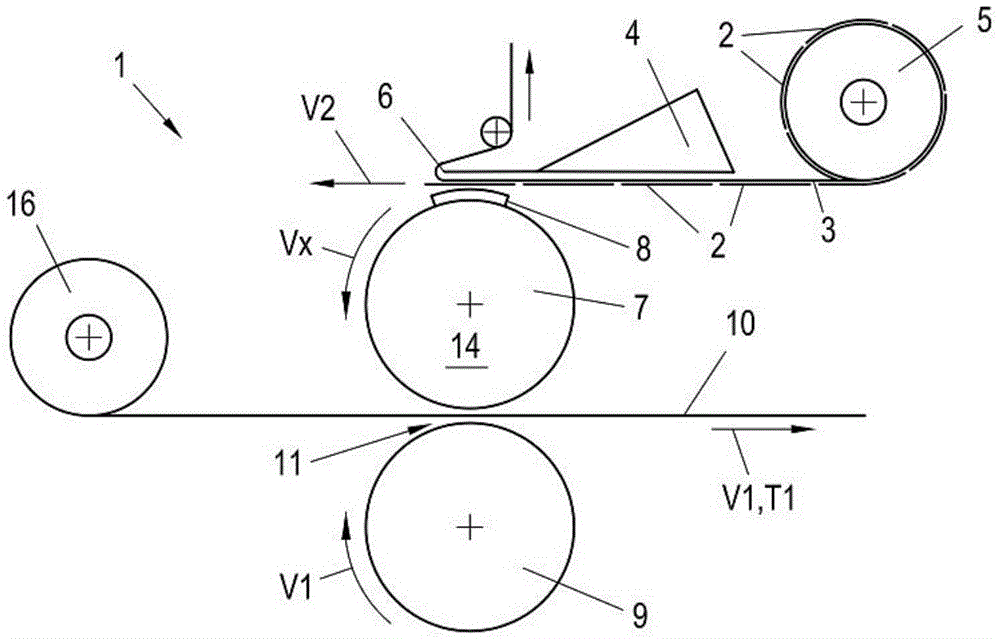

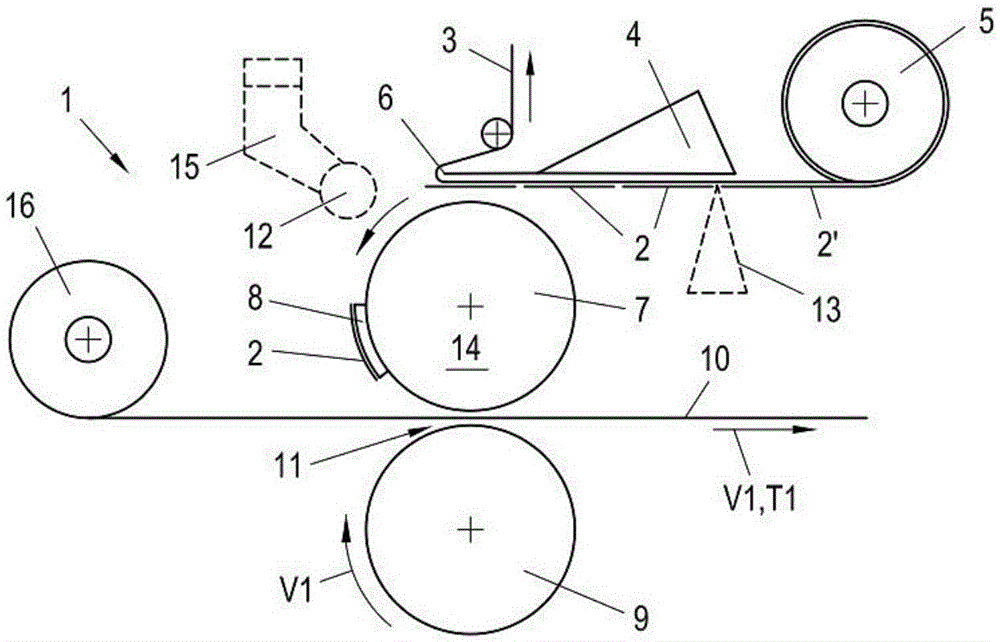

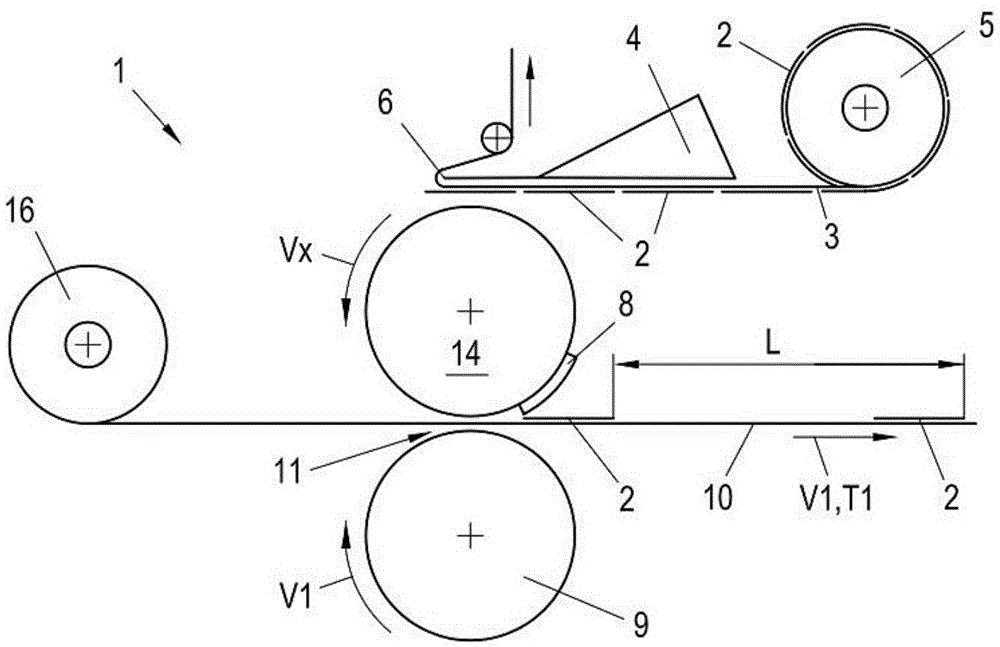

[0024] now refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 A labeling device 1 according to the invention is shown schematically. The labeling device 1 serves to apply a label 2 onto a material web 10 which is moved in a transport direction T1 at a web speed V1. In order to perform this task, the labeling device 1 comprises a label dispenser 4 and a transfer device 7 which transfers the labels 2 from the label dispenser 4 to the material web 10 via holding means 8 and transfers the labels 2 at a transfer station 11. 2 is applied to the material web 10. The holding means 8 of the transfer device 7 are able to circulate in the circulation path at a variable circulation speed V X is moved along the transport direction T1 and the opposite direction of the transport direction, the cycle speed V X Controlled by a not-depicted mechanical controller such that the holding means 8 are moved in the transport direction T1 at the web speed V1 when the holding means 8 is in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com