Photovoltaic module and manufacturing process thereof

A technology for photovoltaic modules and manufacturing processes, applied in photovoltaic power generation, sustainable manufacturing/processing, electrical components, etc., can solve problems such as technical bottlenecks, limitations, and failure to achieve large-scale mass production, to eliminate current loss and reduce debris the effect of the possibility of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

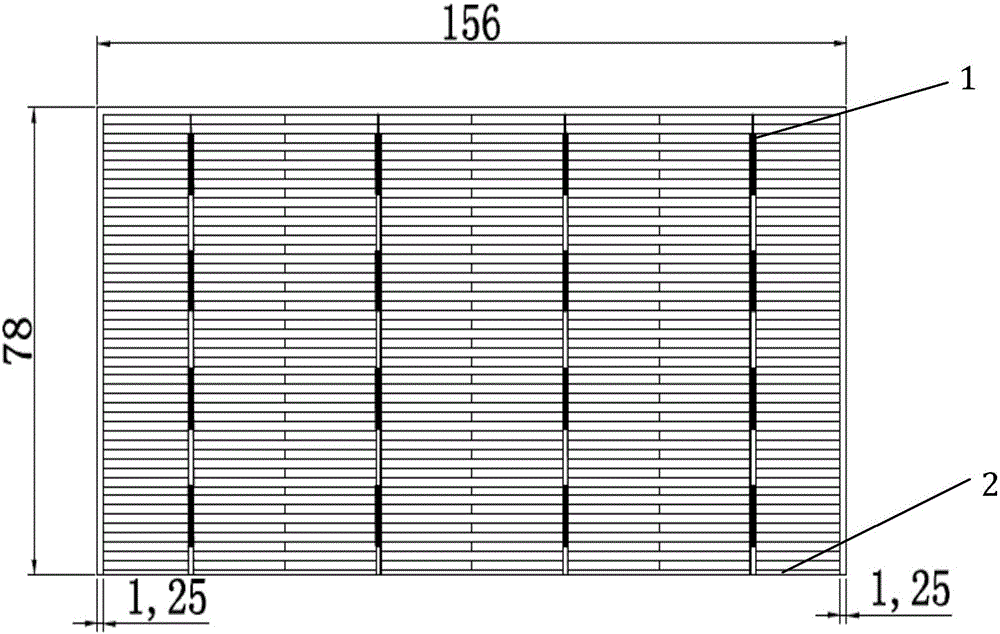

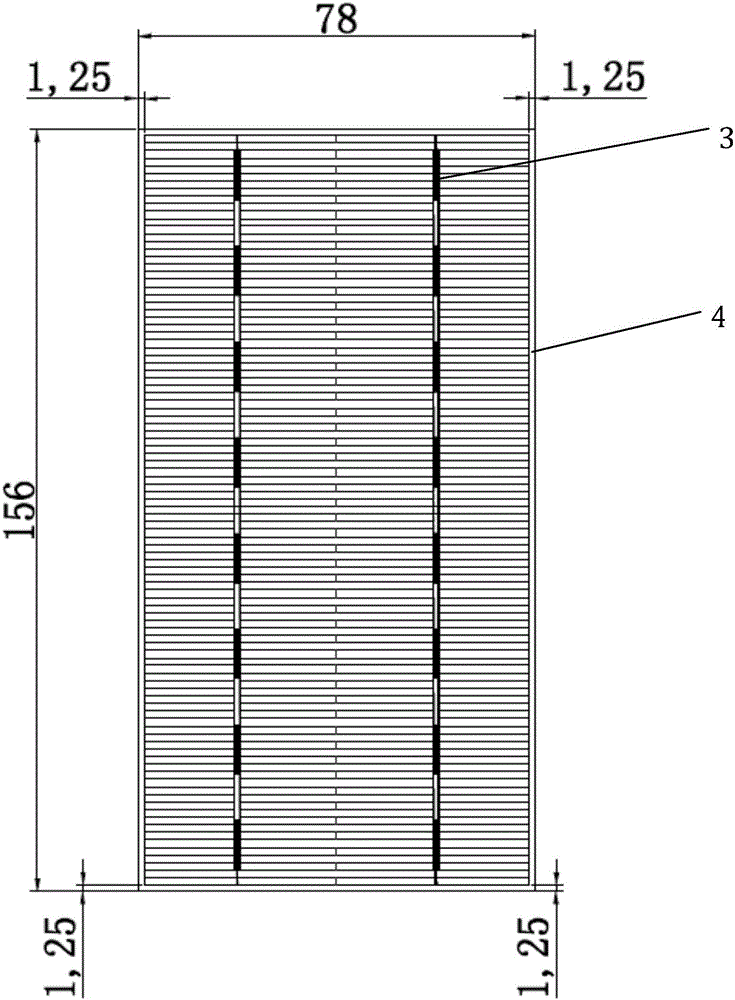

[0027] Embodiment 1: as figure 2 The photovoltaic module shown includes several slices of solar cells. The slices of solar cells are formed by cutting the solar cells. , this effect will be reduced due to the position parallel to the laser sliced lobes during welding.

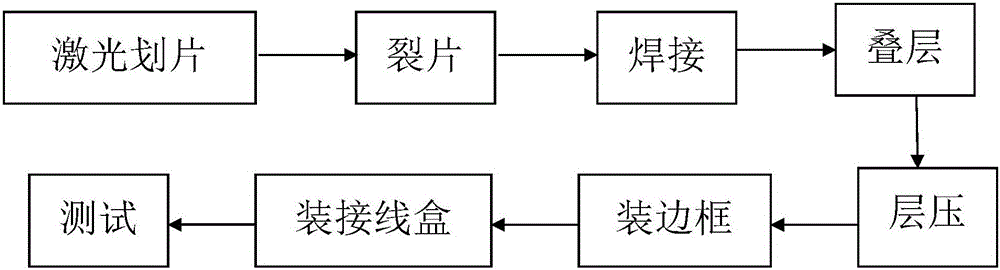

[0028] Since the present invention performs laser slicing in a direction parallel to the main grid, if the image 3 The production process of the conventional half-cell module shown is a series of steps of laser scribing, splitting, welding, lamination, lamination, frame installation, junction box installation, and testing. The welding volume of the battery sheet is double that of the original production line , additional welding equipment needs to be added and modified.

[0029] In order to adapt to laser slicing parallel to the direction of the main grid, the present invention changes the sequence of welding, laser scribing, and slivers. Figure 4 The component preparation process shown is carried out, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com