Arsine and chlorine combined electrolysis device and arsine and chlorine combined electrolysis method using same

An electrolysis device, chlorine technology, applied in the electrolysis process, electrolysis components, electrodes and other directions, can solve the problems of high cost, difficult operation, cumbersome process, etc., and achieve the effect of improving the reliability of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

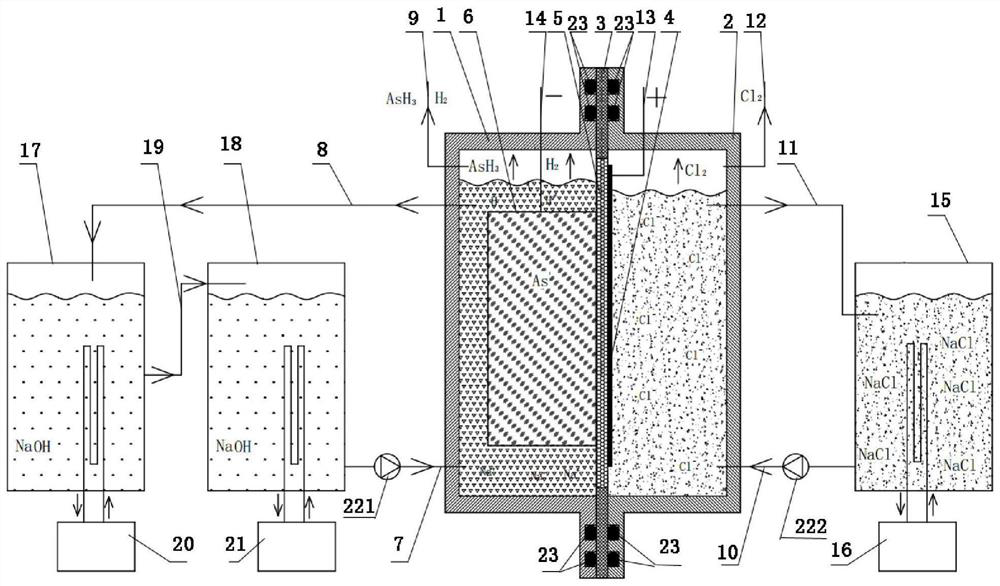

[0097] This embodiment provides an arsenic and chlorine combined electrolysis device, the structural schematic diagram of which is as follows figure 1 shown. The device comprises a cathode electrolyzer 1, an anode electrolyzer 2, a membrane fixing frame 3, an anode membrane electrode 4, a cationic semipermeable membrane 5, an arsenic cathode 6, a catholyte feed pipe 7, a catholyte outlet pipe 8, an arsenic Alkane discharge pipe 9, anolyte feed pipe 10, anolyte discharge pipe 11, chlorine gas discharge pipe 12, anode cable 13, cathode cable 14, anolyte storage tank 15, anolyte constant temperature cooler 16 , catholyte crystallization tank 17, catholyte storage tank 18, crystallization liquid outlet pipe 19, crystallization out cooling machine 20, catholyte constant temperature cooling machine 21, first circulation pump 221 and second circulation pump 222 and seal twenty three.

[0098] An anodic membrane electrode 4 is arranged in the anode electrolysis cell 2 , and the anod...

Embodiment 2

[0116] The arsine and chlorine combined electrolysis device provided in this embodiment are all the same as the arsine and chlorine combined electrolysis device provided in Example 1 except that the anode membrane electrode 4 is a titanium mesh electrode coated with an iridium oxide catalyst on the surface. same.

[0117] This embodiment also provides a method for using the device to perform combined electrolysis of arsenic and chlorine gas. In this method, except that the anolyte solution is a high-purity sodium chloride solution with a concentration of 15 wt%, the temperature of the anode electrolysis is 75° C., and the temperature of the cathode electrolysis is also It is 75 ℃, correspondingly adjust the anolyte in the anolyte storage tank 15 and the catholyte temperature in the catholyte storage tank 18 to be 75 ℃, adjust the crystallization temperature of the catholyte crystallization tank 17 to be outside 5 ℃ , other operations are the same as the method of embodiment 1....

Embodiment 3

[0120] This embodiment provides a method for utilizing the device of Embodiment 1 to carry out combined electrolysis of arsenic and chlorine gas. In this method, except that the anolyte solution is a high-purity sodium chloride solution with a concentration of 25 wt%, the temperature of the anode electrolysis is 85°C, and the temperature of the cathode electrolysis is 85°C. The temperature of the temperature is also 85 ℃, correspondingly adjust the anolyte in the anolyte storage tank 15 and the catholyte temperature in the catholyte storage tank 18 to be 85 ℃, adjust the crystallization temperature of the catholyte crystallization tank 17 to be 15 Except ℃, other operations are all the same as the method of embodiment 1.

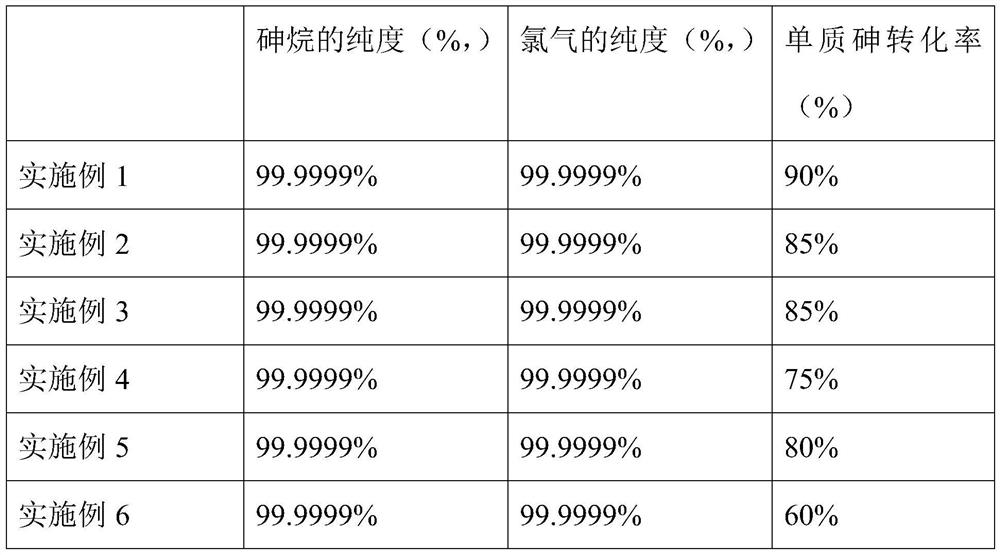

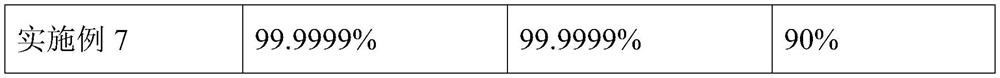

[0121] The purity of arsine, the purity of chlorine and the conversion rate of elemental arsenic in the arsenic electrode obtained by the method of this embodiment are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com