A self-circulating automatic wheel hub pressure maintaining oil system for a large bulb tubular unit

A light bulb through-flow and fully automatic technology, which is applied in the direction of machines/engines, mechanical equipment, safety devices, etc., can solve the problems of short service life of equipment, high power consumption, and heavy operation and maintenance workload, so as to reduce plant consumption. The effect of improving the power utilization rate, improving the reliability of safe operation, and reducing the workload of operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

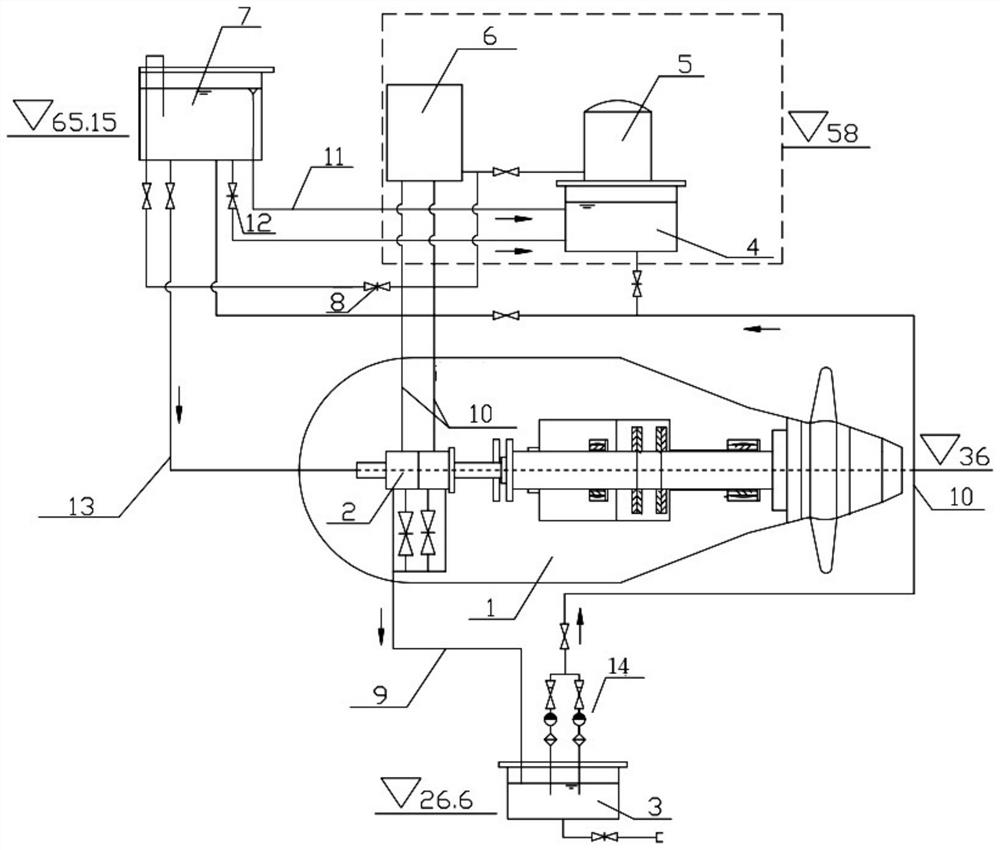

[0020] like figure 1 As shown in the figure, a self-circulating automatic wheel hub pressure maintaining oil system of a large-scale light bulb tubular unit is mainly composed of the self-circulating automatic wheel hub pressure maintaining oil system, which consists of a bulb tubular unit 1, an oil receiver 2, and an oil collecting device 3. , return oil tank 4, high pressure oil tank 5, governor 6, hub high level fuel tank 7, oil filling valve 8, oil receiver oil leakage pipe 9, high pressure oil pipe 10, oil spill pipe 11, wheel hub high level fuel tank manual oil drain valve 12 , the hub pressure maintaining oil pipe 13 and the oil leakage pump 14 and so on.

[0021] The bulb tubular unit 1 is arranged in the flow channel, the oil receiver 2 and the oil leakage pipe 9 of the oil receiver are located in the bulb head of the unit, and the oil collecting device 3 is located in the 26.6m corridor at the lower part of the runner room of the unit. 8. High-pressure oil tank 5, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com