Online automatic counterpoint method and device for inner tube transferring mould and delay element screening mould

An automatic alignment and delay technology, applied to detonators, offensive equipment, etc., can solve problems such as ignition delay, safety accidents, failure to meet product delay requirements, etc., achieve simple structure, realize on-line production, and avoid multiple The effect of the transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

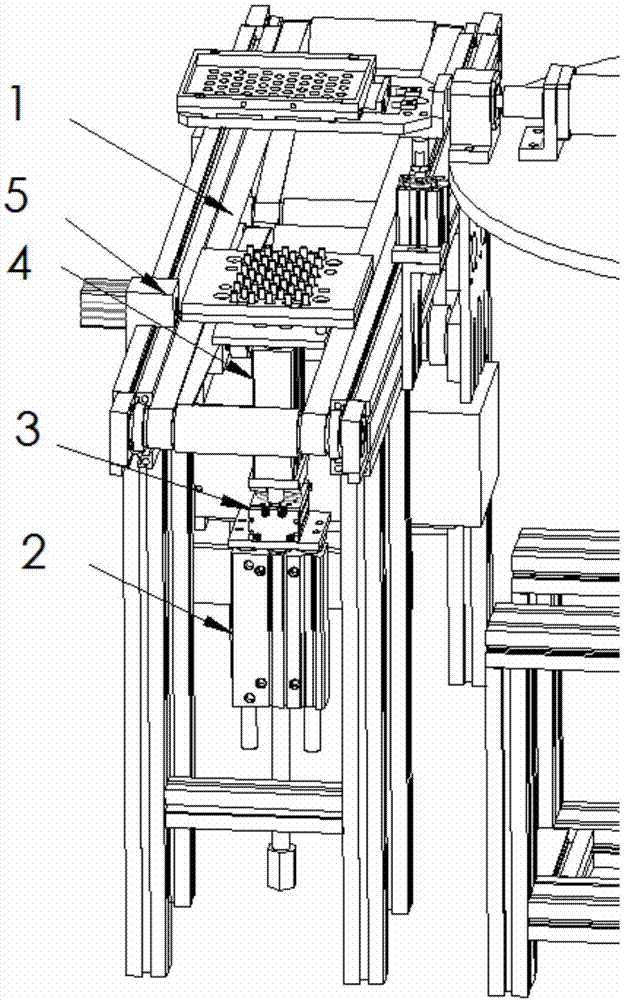

[0009] Embodiment of the present invention: the online automatic alignment method between the inner pipe transfer mold and the delay body sieve row mold, so that the delay body sieve row mold of the sieved delay body is at the top of the conveying line, and the width direction of the delay body sieve row mold is parallel to the conveying line The conveying direction of the line, the transfer mold equipped with the inner pipe is conveyed through the conveying line, the length direction of the transfer mold is parallel to the conveying direction of the conveying line, and the conveying is stopped when the transfer mold is conveyed to the bottom of the delay screen row mold, and the mold is used Alignment device, first lift the transfer mold by one stroke, and then rotate it, so that the position of the transfer mold and the delayed body screen row mold are completely corresponding, and then lift up the second stroke, so that the transfer mold is completely aligned and fit on the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com